|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

C 1, TM 9-2815-213-34

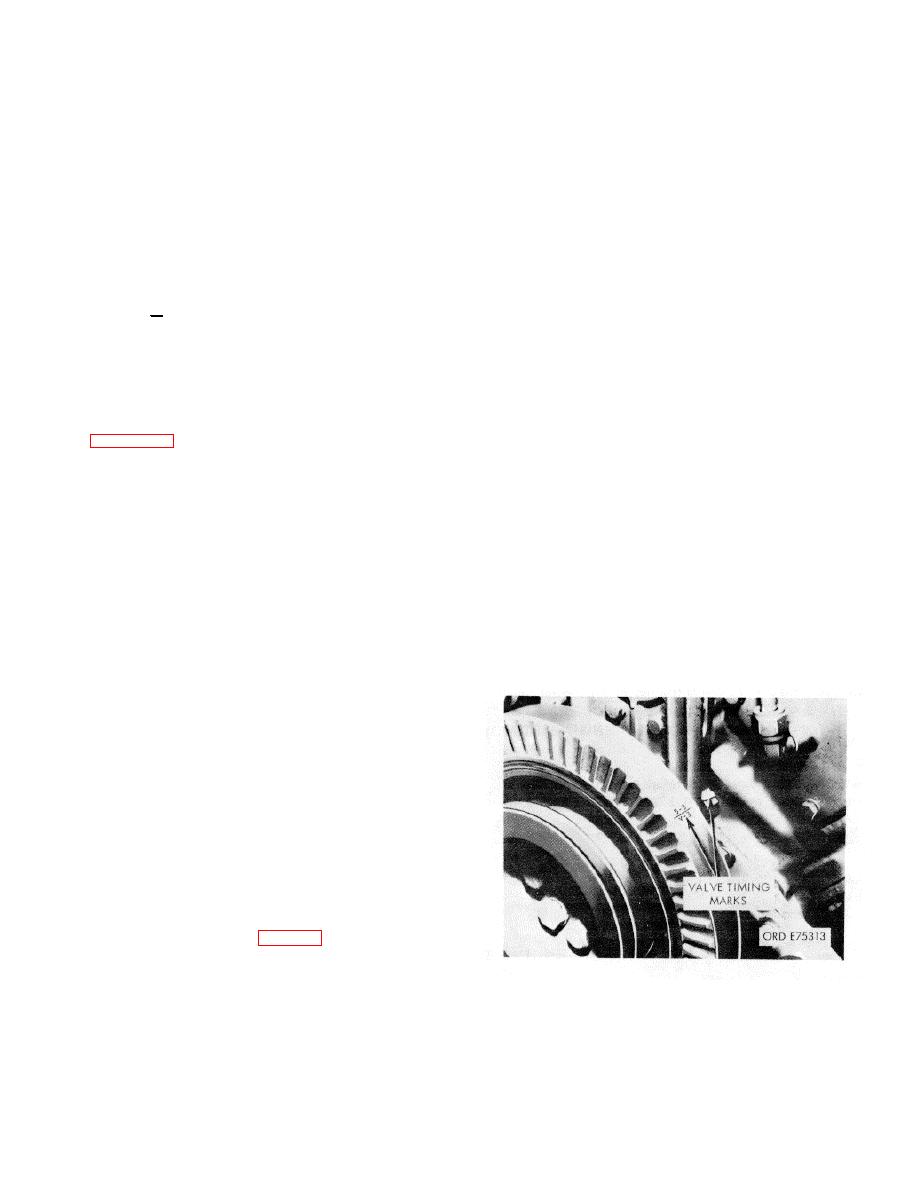

(3) Valve timing marks are located on the

(4) Advance adjusting screw slightly, then

vibration damper at the front of the engine (95).

loosen. Retighten adjusting screw until valve contact is

made.

(5) Tighten 7/16 inch high locknut 60 to 70 foot-

CAUTION

pounds torque.

Check that index marks on outer ring an

(6) Check clearance between crosshead and

hub of vibration damper aline. If no

valve spring retainer with a wire gage. There must be a

replace vibration damper.

minimum of 0.025 inch clearance at this point.

d. Value Clearance.

(4) To aline the timing marks rotate engine

manually in a counterclockwise rotation (left-hand as

viewed from flywheel low towards the fan) until one of the

NOTE

47

is in line with the "A" arrow head on the

sets of marks

The same engine position used in

vs.

In this position, both intake exhaust

front cover.

setting the injectors is used for setting

valves will be closed for one of the cylinders indicated.

the intake and exhaust valves.

Make adjustments or cylinder.

(5) Adjust injector plunger, then cross] and

(1) Loosen the locknut and back-off the

valves of each cylinder as explains succeeding

adjusting screw. Insert feeler gage between rocker lever

paragraphs. Turn crankshaft wise to the next VS mark

and top of crosshead; turn screw down until lever just

corresponding to order of the engine which is 1-5-4-8-6-

touches the gage. Lock adjusting screw in position with

3-7-2 figure 3-96 for complete sequence of adjusts

locknut.

(6) After injectors,

crossheads and v are

(2) Always make final valve adjustment after

adjusted for this cylinder, rotate crankshaft in direction of

injectors and crossheads are adjusted and with the

rotation (right-hand the next VS mark corresponding to

engine at operating temperature (140 degrees

the order of the engine and repeat the adjust

Fahrenheit). Valve clearances are as follows: Intake

procedures.

Valves: 0.016 inch at 70 degrees Fahrenheit, 0.014 inch

at 140 degrees Fahrenheit. Exhaust Valves: 0.029 inch

NOTE

at 70 degrees Fahrenheit, 0.027 inch at 140 degrees

Two complete revolutions (720 degrees)

Fahrenheit.

the crankshaft are needed to set all

(3) Position valve covers to heads with new

injector plungers,

crossheads and

gaskets. Secure with flatwashers, lockwashers, and

valve: Injectors, crossheads and valves

cap screws.

can E adjusted for only one cylinder at

any or VS setting.

3-168. Starting and Testing

b. Injector Plungers.

Engine break-in and testing are accomplished together.

(1) Turn adjusting screw down until plunger just

Break-in on a new or rebuilt engine is

contacts cup, then advance an addition degrees to

squeeze oil from cup.

(2) Loosen adjusting screw one turn.

(3) With a torque wrench calibrated in pounds

and a screwdriver adapter, tighter adjusting screw for a

cold setting (70 de Fahrenheit) at 50 inch-pounds torque.

setting 140 degrees Fahrenheit 50 inch-pounds.

c. Valve Crossheads.

(1) Loosen valve crosshead adjusting locknut

and back off screw one turn.

(2) Use light finger pressure at "A" to

crosshead in contact with valve stem at point "B" (fig 3-

97).

(3) Turn adjusting screw down until contacts its

mating valve stem at point "C' (fig. 3-97).

Figure 3-95. Valve timing marks.

3-58

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |