|

|||

|

|

|||

|

Page Title:

Figure 3-56. Injector body and plunger markings. |

|

||

| ||||||||||

|

|

*TM 9-2815-213-34

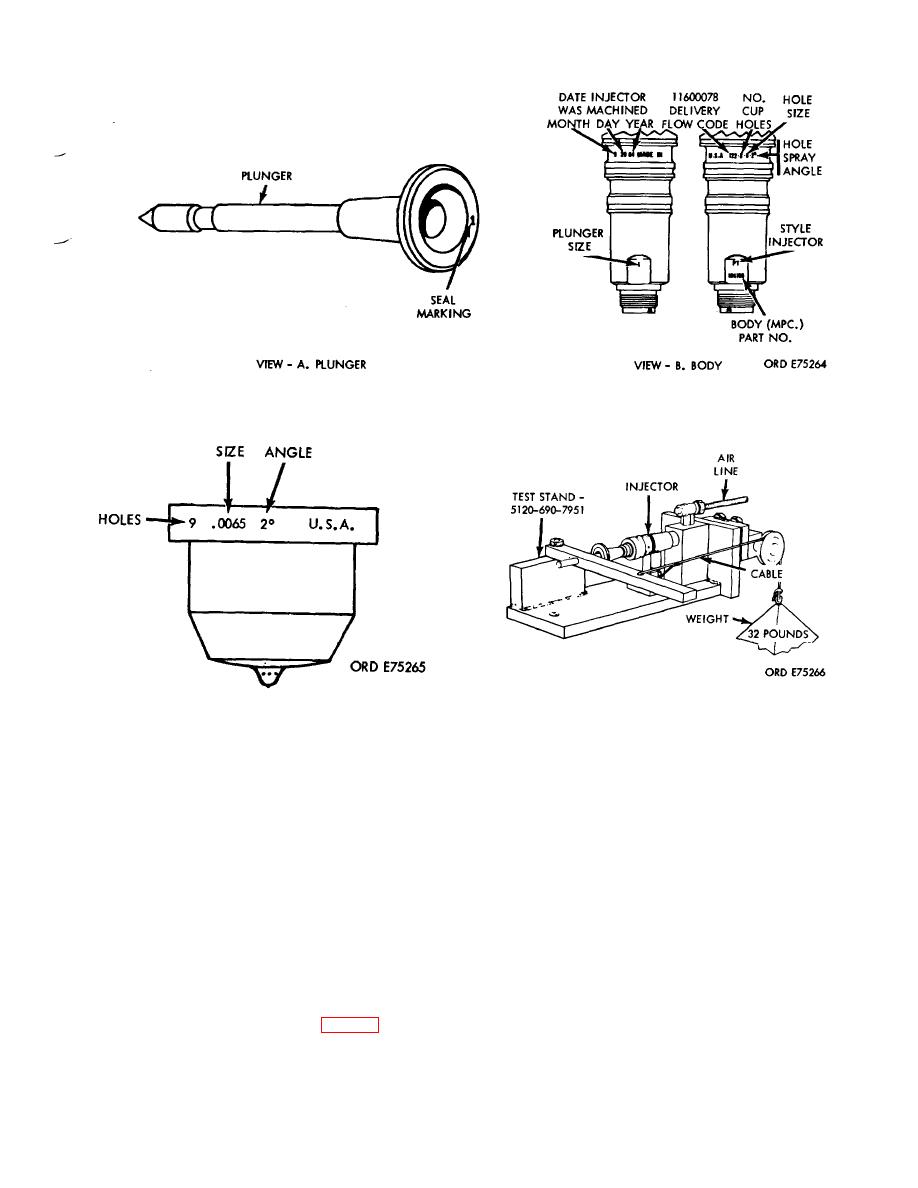

Figure 3-56. Injector body and plunger markings.

Figure 3-58. Injector plunger seat test.

Figure 3-57. Injector cup marking.

10) If the cup seat is damaged in any way and

tors.

It flow tests the complete injector assembly by

injector does not pass cup-to-plunger seat test,

measuring fuel delivery. The injector is actuated under

plunger may be lapped into cup to obtain good

controlled conditions closely simulating actual operating

seating. Use no greater than 300 grade lap- ping

conditions. The test stand counts injection strokes, supplying

compound mixed with OE30 lubricating oil. Applying

fuel at specified pressure, and measures the delivery in a

light pressure, oscillate plunger in cup back and forth

glass graduate.

The following preliminary steps and

for approximately one minute.

procedures are required prior to test stand operation.

CAUTION

CAUTION

Before operating the test stand make sure that the

After lapping, both the cup and plunger must

cam box is filled to the level of the sight glass with

be thoroughly cleaned. Lapping compound

OES-30 oil.

will damage fuel system unless removed.

The most effective cleaning process is the

NOTE

use of an ultrasonic cleaner, if available, and

an after rinse in fuel oil.

The test stand must be located near hot and cold

(11) If injector is satisfactory, remove

water connections. Water temperature, controlled by

plunger. Re-install spring and plunger.

a mixing valve, is used to maintain test fuel at an

80/100 degree Fahrenheit temperature

The injector test stand is used to test all injec.

range.

3-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |