|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

is less than "10" seconds valve seat is unsatis- factory. (7)

If valve seat seal is unsatisfactory:

(a) Check for leaking connections on tester.

(b) Operate tester with suction cup against

clean glass plate.

(c) Check for dirt on valve and seat.

(8) If necessary regrind valve seat (para. 3-

68.e.).

NOTE

It is possible to mistake leakage around the

valve seat insert for valve seat leakage. If

this is suspected, apply grease to the

outside edge of the insert to make a grease

seal.

Perform vacuum test and insert grease

seal for a "break" indicating air leakage

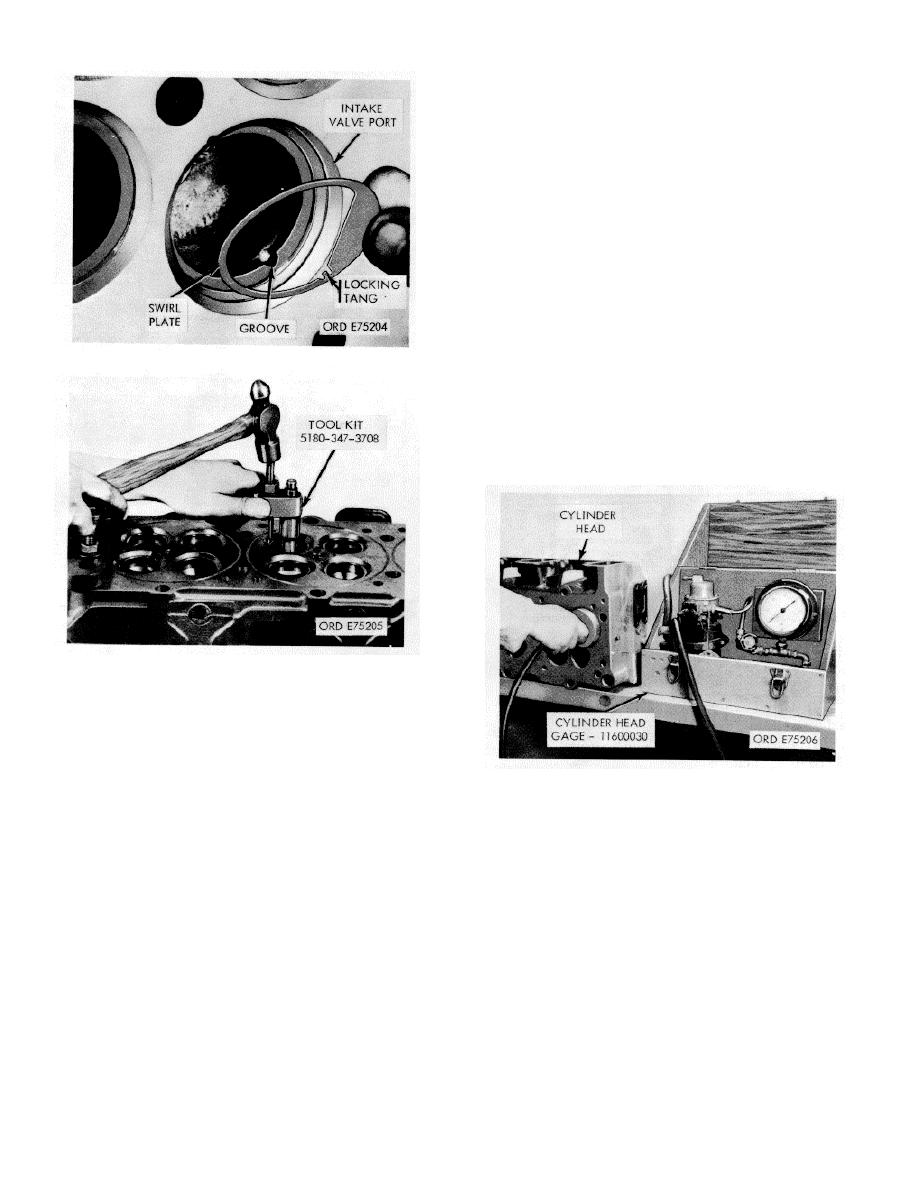

Figure 3-45. Intake valve port swirl plate-installation

between wall of counterbore and valve seat

insert. If leak around insert is detected,

correction is required before continuing with

test

b. Head Assembly. Perform a water test on the

rebuilt head assembly (para. 366.c.).

Figure 3-46. Valve seat insert peening.

(2) Valve and seats must be dry and clean.

Place suction cup over valve head. O-Ring on cup

should seat on flat surface of head surrounding

valve. Grease area lightly with GAA for a better seal.

(3) Turn hand shut-off valve to open

Figure 3-47. Valve seat test.

position. Hold push button down to operate vacuum

pump.

3-70. Installation

(4) Operate vacuum pump until hand on

vacuum gage stops climbing at 15/25 inches of

a. Make certain pipe plugs are installed and

mercury on the dial.

secure.

(5) Close shut-off valve; release push button

b. Clean mating surfaces of cylinder block and

to stop pump.

cylinder heads. Make certain cylinder walls are

(6) Time vacuum pressure decrease on

clean and well lubricated with OE-10 engine oil.

gage

c. Place grommet retainers in water passages

to test valve seat.

in block, small end up.

(a) "Start" timing as soon as hand

d. Lay gasket on flat surface. Press grommets

reaches "15" inches of mercury on dial.

in place by hand.

(b) "Stop" timing when hand reaches

e. Install head gaskets over ring dowels so that

"12" inches of mercury on dial, if elapsed time

3-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |