|

|||

|

|

|||

|

Page Title:

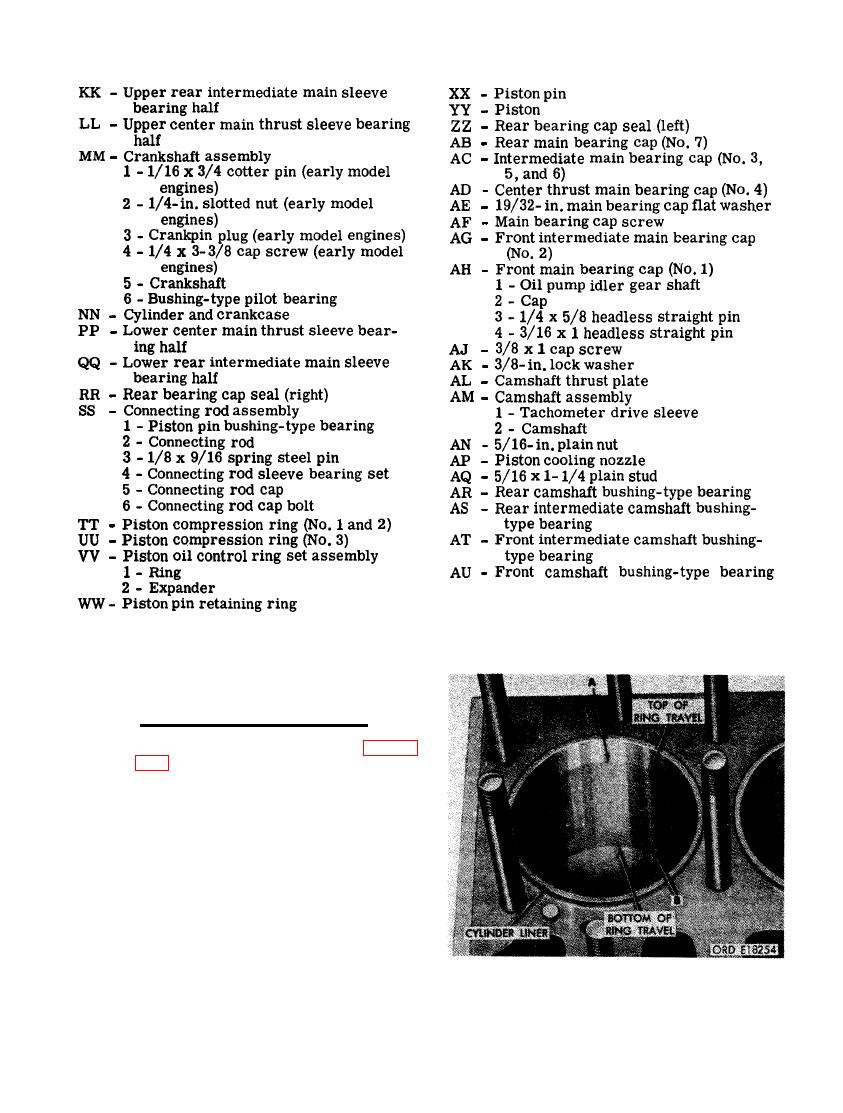

FIGURE 323. POINTS OF MEASUREMENT FOR CHECKING CYLINDER LINER BORES. |

|

||

| ||||||||||

|

|

FIGURE 322. CYLINDER AND CRANKCASE, CRANKSHAFT, PISTON, AND

RELATED PARTS - EXPLODED VIEW - CONTINUED

(3) Cylinder liner bore dimensions. Check

dimensions against limits specified in

repair and rebuild standards. Figure

take two measurements of cylinder liner

bore near top, just below ring travel.

Measure diameter approximately paral-

lel to crankshaft center line and then

take cross measurement (90 degrees) to

first measurement. Average the two

measurements. (B) Take two measure-

ments of liner diameter bore at bottom

of ring travel at lower end of liner.

Measure diameter of bore approxi-

mately parallel to crankshaft center

line, and then take cross measurement

(90 degrees) to first measurement.

Average the two measurements.

FOR CHECKING CYLINDER LINER BORES.

197

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |