|

|||

|

|

|||

|

Page Title:

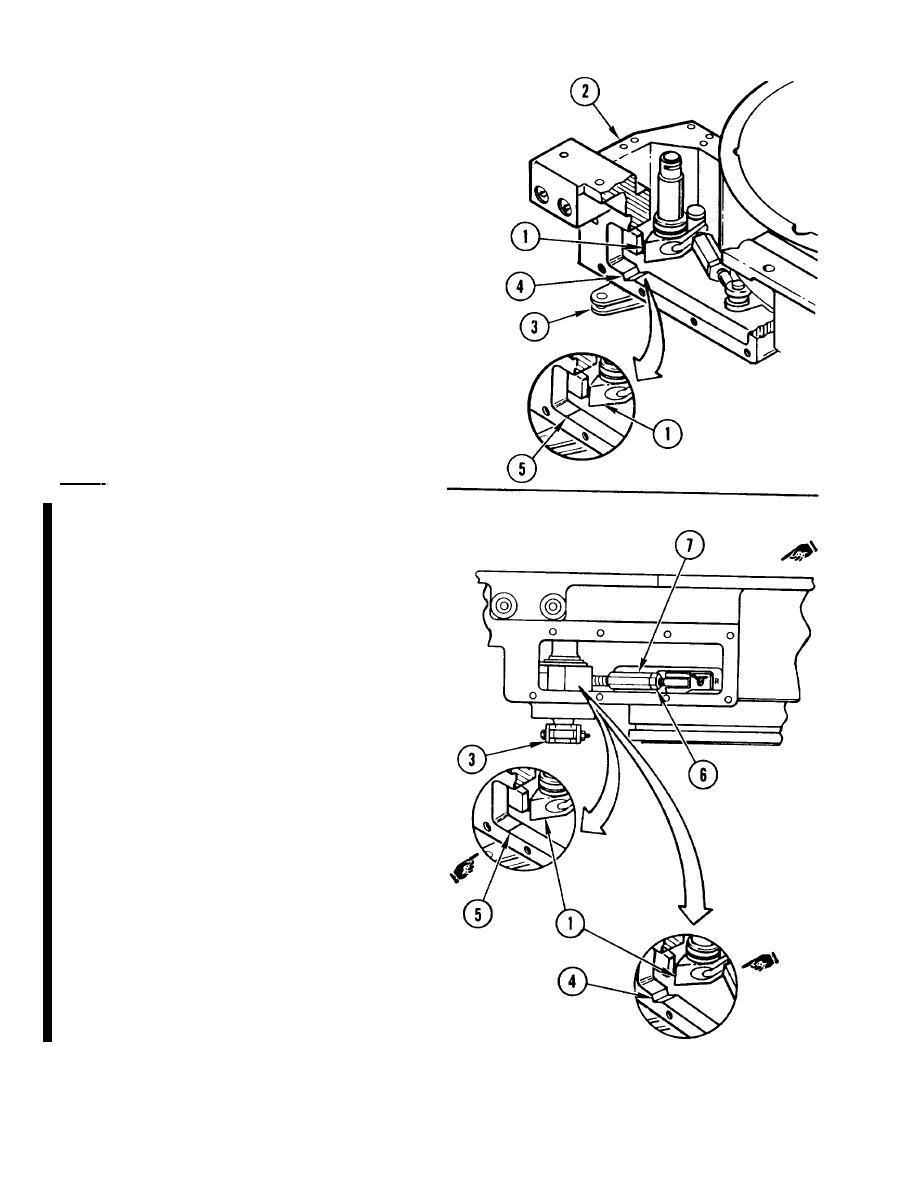

CHECK ALINEMENT OF SHOULDERED SHAFT POINTER |

|

||

| ||||||||||

|

|

TM 9-2520-270-34

NOTE

Two different alinement indicators are used

in the output assemblies.

17. CHECK ALINEMENT OF SHOULDERED

SHAFT POINTER (1).

a. Repairer and helper turn right-hand

output housing (2) over.

b. Rotate lever arm (3) and apply firm

pressure.

c. Check that pointer (1) alines with

v-groove indicator (4) or scribe mark

indicator (5).

d. If pointer (1) does not aline with

indicator (4) or (5), go to step 18. If

pointer does aline with indicator,

go to step 19.

NOTE

Two different alinement indicators are used

in the output assemblies.

This procedure contains only a coarse pointer

adjustment. The fine pointer adjustment is

done in the vehicle.

18. ADJUST POINTER (1).

a.

Release lever arm (3). Loosen jam

nut (6).

b.

Adjust pointer (1) by rotating adjuster

nut (7). Tighten jam nut (6).

c.

Rotate lever arm (3) and apply firm

pressure.

d.

Check that pointer (1) alines with

v-groove indicator (4) or scribe mark

indicator (5).

e.

If pointer (1) does aline, go to

step 18.1. If after repeated adjustments

pointer (1) will not aline, go to

step 20.

18.1 U S I N G 1/2-lNCH DRIVE TORQUE

WRENCH WITH ADAPTER AND

9 / 1 6 - l N C H CROWFOOT, TORQUE

NUT (6) TO 17-20 ft-lb (2-3 mkg).

4-274

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |