|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-249-34&P

above the surface of input pump body (25).

b. If bearing (27) was removed from input

flat washers (10), and input pump cover assembly (6)

pump body (25), install a new replacement from the

from input pump body (25).

pump gear cavity side of the pump body. Press the

c. Do not remove bearing (7) from input pump

bearing 0.005 to 0.010 inch below the surface adjacent

cover (8) unless replacement is necessary.

to the bearing bore of the pump body.

d. Remove ball (11) from idler shaft (12).

c. Install input pump drive gear shaft (22) into

e. Remove idler shaft (12) and idler gear

input pump body (25).

assembly (13) from input pump body (25).

d. Install driven gear roller (3) and driven gear

f.

Do not remove bearings (14) and (16) from

(4) onto input pump drive gear shaft (22).

idler gear (15) unless replacement is necessary.

g. Remove retaining ring (5) from input pump

pump drive gear shaft (22).

drive gear shaft (22).

f.

Install idler gear shaft (12) into input pump

cover (8).

gear roller (3) from input pump drive gear shaft (22).

i.

Remove input pump drive gear shaft (22)

idler gear (15), install replacements.

Install each

from input pump body (25).

bearing, pressing against the numbered side of the

j.

Do not remove bearing (27) from input

cage, 0.005 to 0.010 inch below the surface on each

pump body (25) unless replacement is necessary.

side of the gear.

k. Do not remove dowel pins (24 and 26)

h. Install idler gear assembly (13) onto idler

unless replacement is necessary.

shaft (12).

i.

If bearing (7) was removed from input

7-160. Cleaning

pump cover (8), install a new replacement. Install the

Refer to

for

cleaning

bearing from the flat side of the cover, pressing against

recommendations.

the numbered side of the cage, 0.005 to 0.010 inch

below the surface of the cover.

7-161. Inspection and Repair

j.

Install ball (11, FO-11) into idler shaft (12),

Refer to paragraph 5 3 for general inspection and repair

using oil-soluble grease to retain it.

recommendations.

k. Install input pump cover assembly (6) onto

input pump body (25) and secure it with eight selflocking

7-162. Repair Standards

bolts (9) and flat washers (10). Tighten the bolts to 17 to

a. Refer to paragraph 5 4 for explanation of

20 pound feet torque.

repair standards.

l.

Install gasket (17) and input pump base

(18) onto input pump body (25).

m. Secure the base with four 3/8-16 x 2 1/2-

7-163. Assembly

inch

bolts, lockwashers, and flat washers. Refer to

a. If dowel pins (24 and 26) were removed,

install new replacements. Press the pins to 0.22 inch

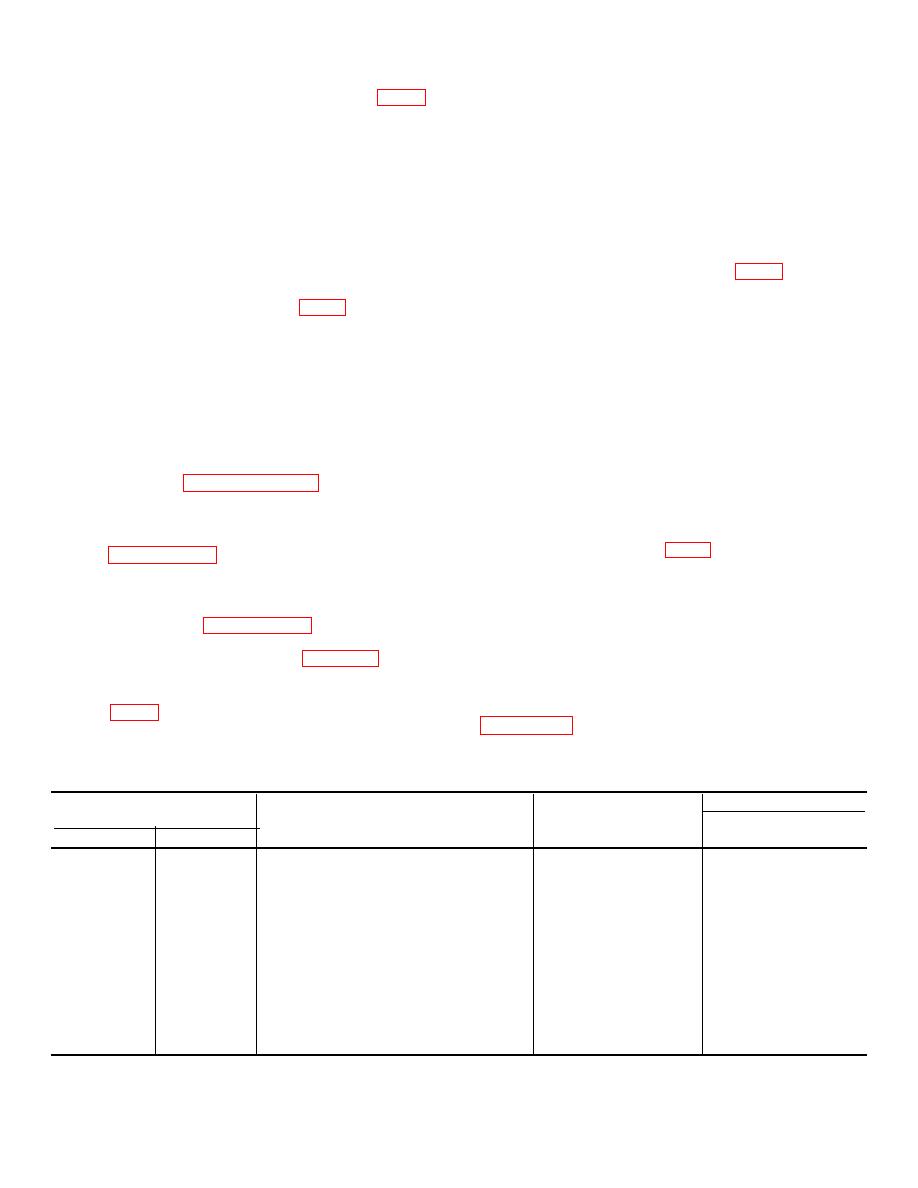

Table 7-23. Repair Standards (Input Oil Pump)

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

11

7a

Outside diameter of bearing .................

To press fit 0.8075

*

to 0.8078 bore

11

8a

Inside diameter at bearing ...................

0.8070 to 0.8075 0.8080

11

7a,

Fit of bearing in cover ..........................

0.0000 to 0.0008T

8a

11

12a

Outside diameter of shaft .....................

0.6245 to 0.6250

0.6242

11

14a,

Outside diameter of bearing To press fit

0.8075

*

16a

............................................................

to 0.8078 bore

11

15a

Inside diameter of gear .......................

0.8075 to 0.8080

0.8085

11

14a,

Fit of bearings in gear ..........................

0.0005L to 0.0003T

15a,

16a

7-50

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |