|

|||

|

|

|||

|

Page Title:

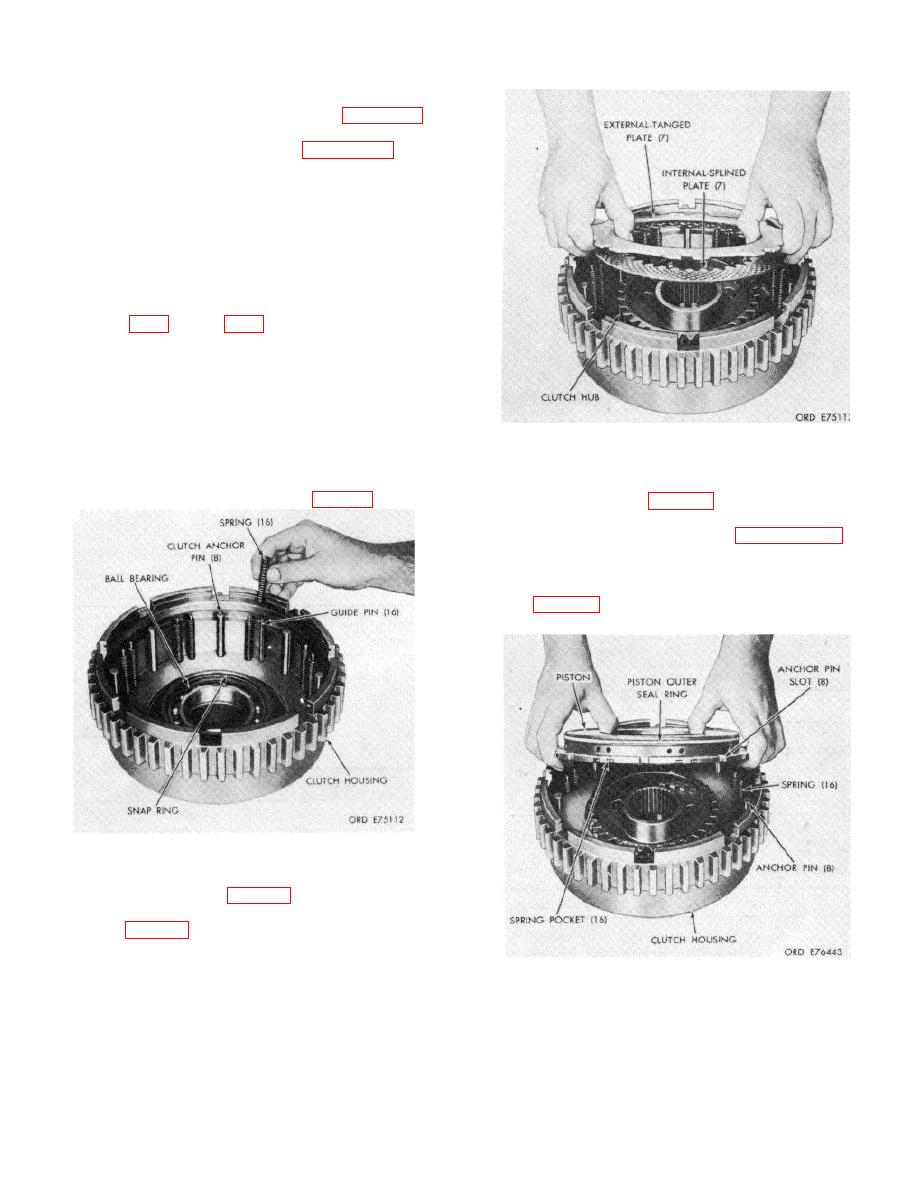

Figure 7-41. Installing output clutch piston return spring. |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

c. Place a flat, smooth plate (approximately 7

x 7 inches) on the clutch plates as shown in figure 7-40.

d. Apply a press force of 600 to 2,000 pounds

on the clutch group as shown in figure 7-40, and

measure and record dimension B.

of the snapring which retains the output clutch piston

housing. Record this as dimension C.

f.

Substitute the three dimensions recorded

for the letters in the formula A (B + C)=clutch clearance.

If the clearance is between 0.070 and 0.090 inch, the

clutch may be assembled from the parts at hand. If the

clearance is greater than 0.090 inch, select a thicker

than 0.070 inch, select a thinner piston.

NOTE

The exact thickness of the piston is etched

on the piston.

Figure 7-42. Installing output clutch plates.

g. With

the

proper

clutch

clearance

established, assemble the clutch as outlined below.

k. Install, alternately, seven internal-splined

h. Install the ball bearing into the clutch

and seven external-tanged clutch plates. beginning with

housing and retain it with the snapring (fig. 7-41).

an internal-splined plate (fig. 7-42).

l.

Install the expander and piston outer

sealring onto the piston as outlined in paragraph 7-55.

m. Install the piston, larger diameter first, into

the clutch housing. Make certain that all of the springs

seat in the counterbored spring pockets in the clutch

piston (fig. 7-43). Shaking the piston will help seat the

springs.

Figure 7-41. Installing output clutch piston return spring.

i.

Install eight clutch anchor pins, 16 spring

guide pins and 16 springs (fig. 7-41).

j.

Install the clutch hub, shorter side of hub

downward (fig. 7-42).

Figure 7-43. Installing output clutch piston.

7-35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |