|

|||

|

|

|||

|

Page Title:

Determine thickness of laminated shims |

|

||

| ||||||||||

|

|

TM 9-2520-238-34

REPAIR TRANSFER GEARCASE F -- Continued

0019 00

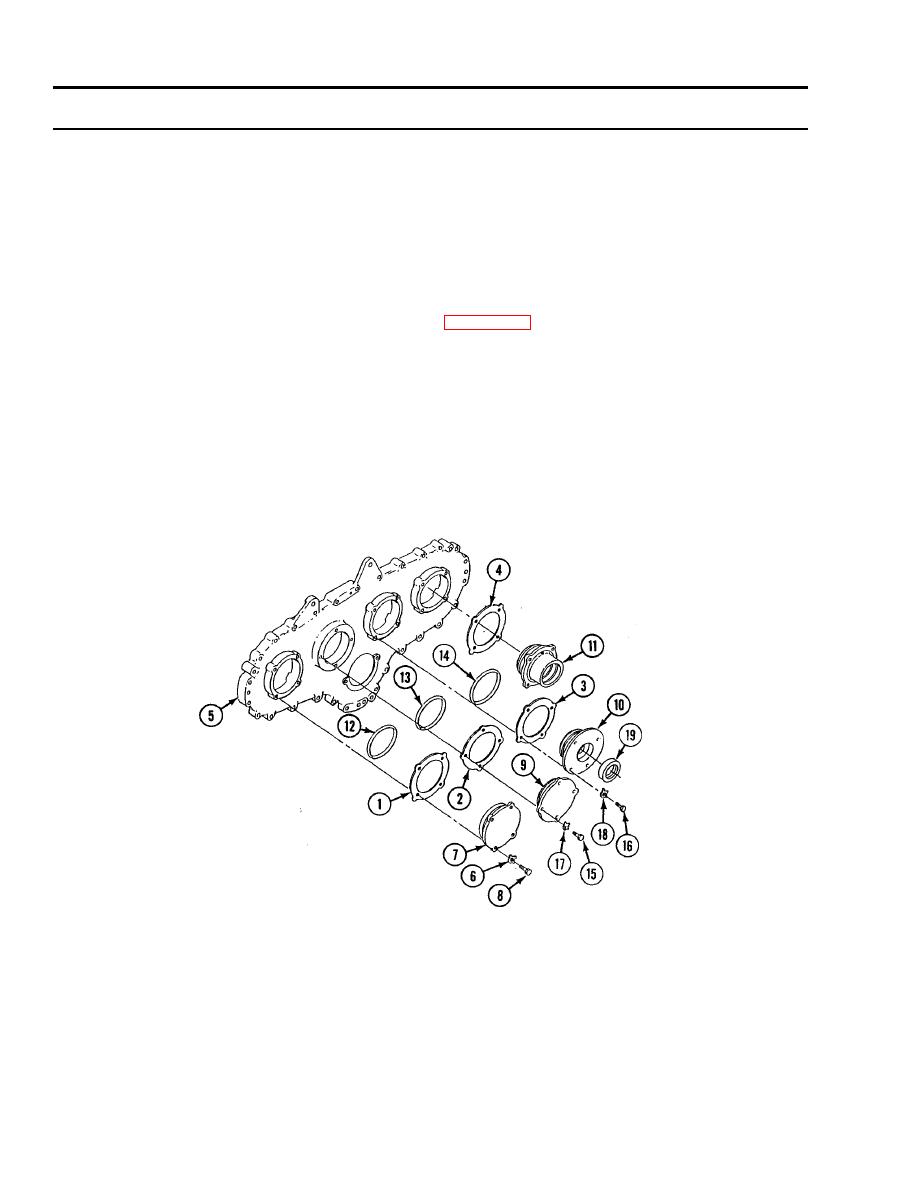

23. Determine thickness of laminated shims (1), (2), (3), and (4) for bearing preload and install shims on cover (5) as

directed in Steps 24 - 30.

NOTE

Install output bearing retaining plate with oil hole up. Most retaining plates have the word TOP

stamped in metal near oil hole.

24. Without new laminated shim (1) and four new key washers (6) installed, place output bearing retaining plate (7) on cover

(5). Lube four cap screws (8) with engine oil and secure retaining plate (7) to cover with four screws. Tighten screws

uniformly to 168-192 lb-in (19-21 N.m). Use torque wrench (WP 0033 00, Item 41).

25. Rotate gear train one revolution by hand in each direction to check freedom of movement. Recheck installation

procedures if binding is detected.

NOTE

Ensure that the secondary pump-drive gear does not interfere with gear rotation. This gear is

nonfunctional until the differential oil pump is installed.

26. Use a thickness gage to measure the gap between output bearing retaining plate (7) and cover (5) at three equal places

around cover. Take the average of these readings and record. Peel shim (1) to 0.003-0.005 inch less than the average

recorded in step above. Remove four cap screws (8) and retaining plate from cover.

0019 00-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |