|

|||

|

|

|||

|

Page Title:

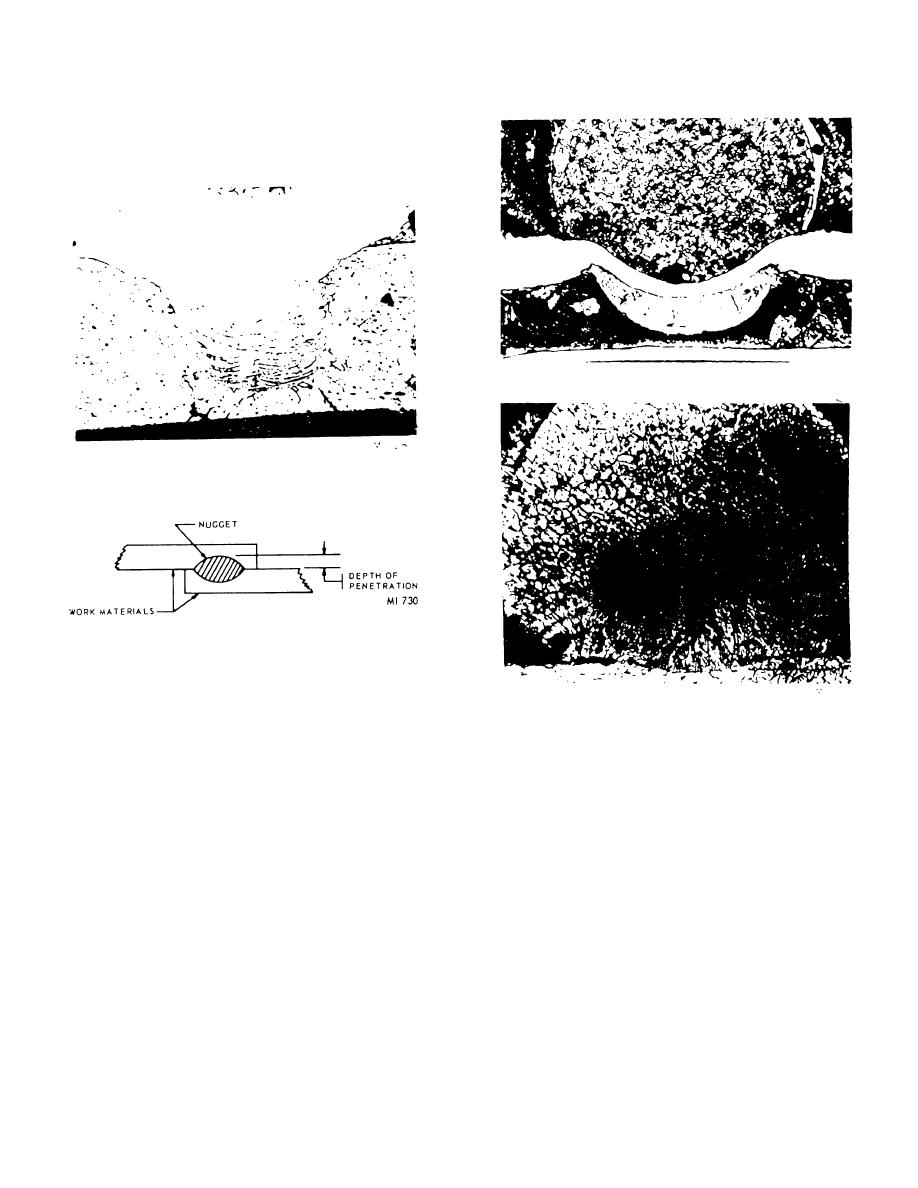

Figure 8-15. Improper heat balance. |

|

||

| ||||||||||

|

|

TM 750-245-4

that is contained within the clad of an interconnecting

material. Improper heat balance can be solved by

methods discussed previously.

Figure 8-13. Excessive heat and pressure resulting

in shrinkage cavities.

Figure 8-14. Proper penetration.

j. A sound weld is accomplished when the clad

has been broken through and proper heat balance has

Figure 8-15. Improper heat balance.

been attained.

k. It has been found, in certain cases involving

I. The value of metallographic analysis is obvious

welding of solder coated leads, that resistance solder

and should be performed on welds produced at machine

joint was produced by the weld process, rather than a

settings to verify the adequacy of the weld parameters

true weld. A similar situation exists when welding dumet

to produce reliable welds.

to an interconnecting material. Here, the copper sheath

However, metallographic analysis and interpretation

melts and forms a brazed joint. Both of these conditions

should be performed by a qualified metallographeror

have been detected by metallographic analysis.

metallurgist.

8-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |