|

|||

|

|

|||

|

Page Title:

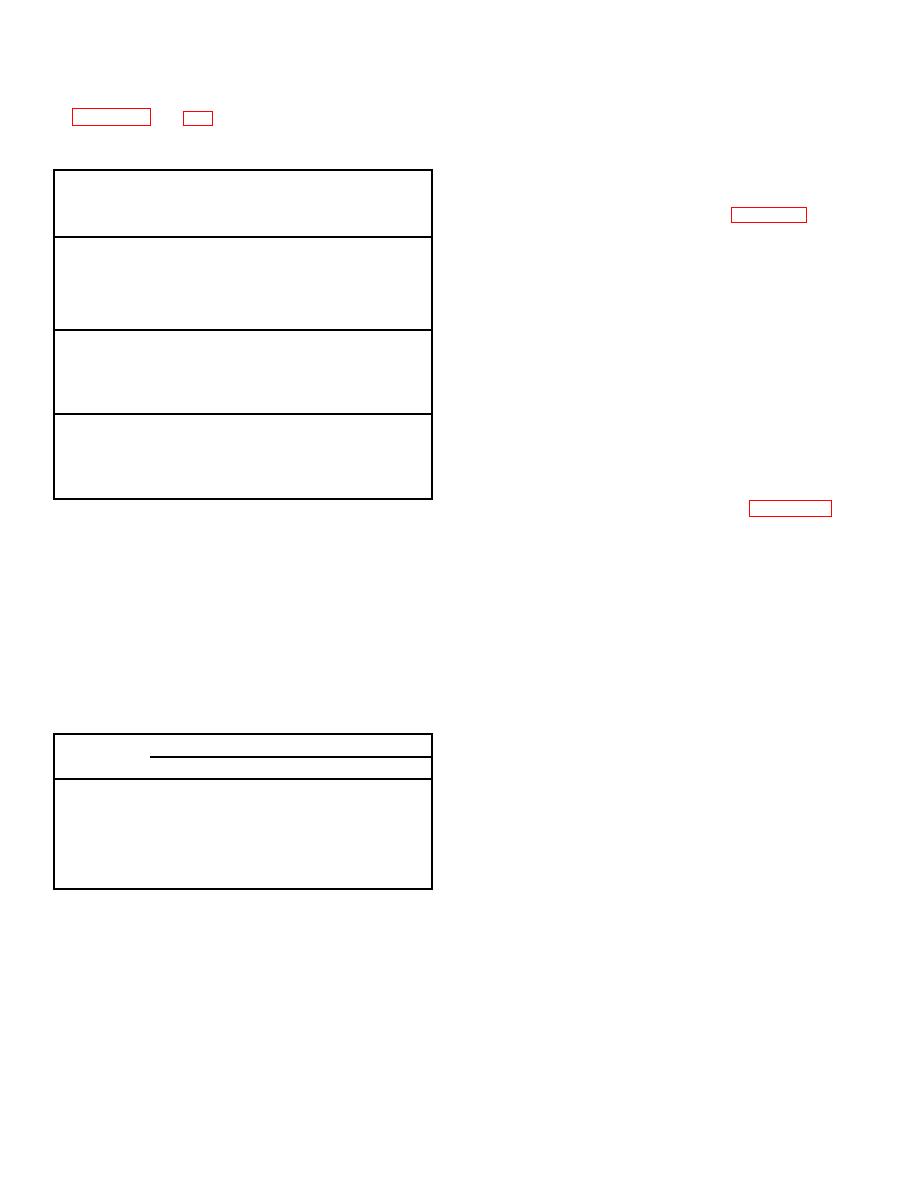

Table 3-1. Foam-in-Place Application (General) |

|

||

| ||||||||||

|

|

TM 746-10

Note

Note

Cushion thicknesses listed are recommended

as minimum thicknesses. Foam selection may

Table 3-1. Foam-in-Place Application (General)

be determined by availability of classes of

foam. The most rigid foam should be selected,

Item

Technique

when feasible, to reduce cube.

weight

(Listed in order

Recommended

(2) Split pack, inverted (fig 3-22).

This

(lbs)

of preference)

foam

class

technique is used for items weighing between 50 and

150 pounds that can be inverted without difficulty and

To 50

Split pack, alternate

* Flexible / semirigid

are not susceptible to damage in the inverted position.

Split pack, standard

"

"

Split pack standard instructions are not furnished in this

Split pack, inverted

"

"

section because of their similarity to split pack inverted

Preformed molding

"

"

instructions. The split pack standard procedures are the

Foamed container

"

"

same except that the item or the box is inverted and the

51-150

Split pack, inverted

Semirigid / rigid

support blocks are not removed. Instead, they become

Split pack, standard

"

"

a part of the cushioning, blocking, and bracing.

Foamed container

"

"

(a) Clean and preserve the item per the

Foam in bag

"

"

appropriate packaging instructions for the individual

Preformed molding

"

"

item. Wrap the sharp corners and projections of the

151-

Split pack, standard

*Semirigid / rigid

item with a suitable cushioning material and secure with

Encapsulated

"

"

tape. Wrap the complete item with polyethylene film

Foamed container

"

"

and secure with tape.

Foam in bag

"

"

Preformed molding

"

"

(b) Measure and weigh the item and select

the appropriate size box, as specified in figure 3-26.

* Items weighing over 200 pounds shall be packed

(c) Close and tape the top flaps of the box,

with rigid class foam. Items weighing over 50

invert the box, and open the bottom flaps.

pounds shall not be packed in flexible class foam.

(d) Select two pieces of blocking from rigid

foam, wood, or any other suitable material that will

Note

temporarily support the item. Cut the blocking to

Recommended techniques and foam classes

dimensions which will allow the item to rest inside the

are listed for normal field packaging

center of the box.

operations. Technique preference may vary

(e) Place the inverted item on the blocks.

according to types of foaming equipment and

availability of packaging materials.

CAUTION

Items that must stay in an upright position to

Table 3-2. Foam-in-Place Cushion Thickness Application

prevent internal damage should not be packed

Item weight

Cushion Thickness (inches) For

using this inverted technique.

(Ibs)

Flexible

Semirigid

Rigid

(f) Drape a piece of polyethylene film over

1-25

3

2

--

the top half of the item covering the item, sides, and

26-50

4

3

2

ends of the box. Secure the top of the sheet to the box

51-75

--

4

3

flaps with tape. The sheet should be secured so the film

76-100

--

5

4

will not sag below the horizontal center of the item while

101-200

--

6

5

the foam is expanding.

201-

--

--

6

(g) Dispense foam. The amount of foam to

dispense is normally predetermined by the equipment

Note

supplier, but the foam should surround the item and fill

the container.

Cushion thicknesses listed are recommended

(h) After the foam has completely

for normal field packaging operations for items

expanded, allow appropriately 15 minutes curing time.

with fragility factors from medium to high.

Trim excess foam (if necessary), fold the polyethylene

Items with known low-fragility factors shall be

sheet over the foam, close the bottom flaps, and secure

packed per the Army Packaging Data

with tape.

Microform File.

(i) Turn the box upright, remove the

temporary blocking, and repeat (X)(f), (g), and (h)

above.

3-37

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |