|

|||

|

|

|||

|

Page Title:

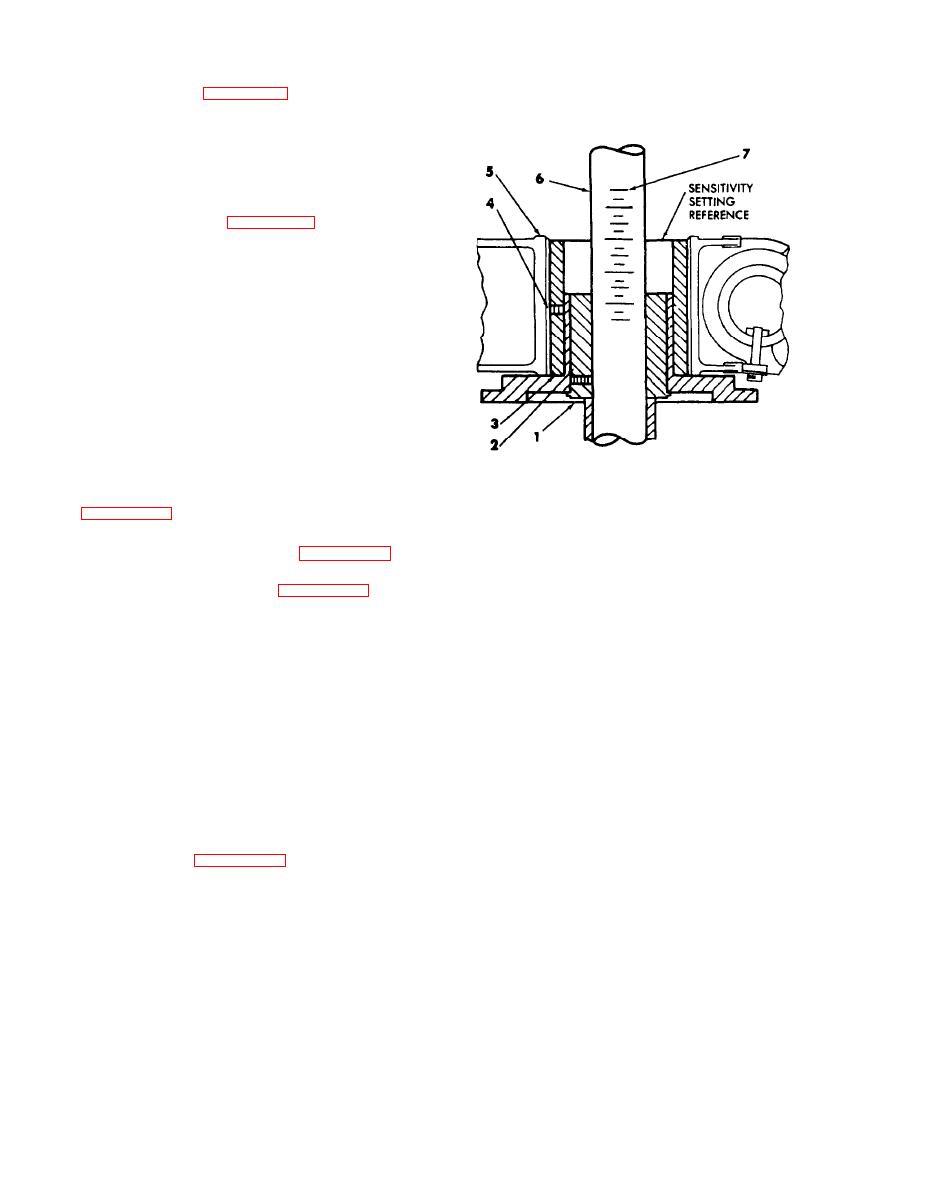

Figure 4-40. Balancer Installation - CH-47 Helicopter Rotor Head Assembly. |

|

||

| ||||||||||

|

|

TM 55-4920-201-14

diameter of sleeve (3, figure 4-40). Insure that rotor

hub seats firmly on shoulder of sleeve or base of

plug (1) as applicable. Allow rotor arms to rest

against droop stops. Position pitch bearing

housings in flat position.

d. Install balancing arbor (6) downward

through center bore of bushing (2). Install quick-

disconnect coupling (10, figure 1-13) with 3 / 16-

inch suspension cable (13) on arbor suspension rod.

Install alternate hoist eye assembly (12) with

"quickie" coupling (11) on end ball of suspension

cable, and attach alternate hoist eye assembly to

suitable shop hoist (not supplied).

NOTE

Since weight of the rotor head assembly

exceeds recommended limits for the 7A050

kit hoist arm structure, use of this hoist arm

with its hydraulic pump assembly is not

recommended in balancing of the rotor

head assembly.

e. Adjust suspended height of balancing arbor

1. Plug (2250, 7HEL054 and

(6, figure 4-40) so that 7-inch position on arbor

7HEL354 kits)

scale (7) aligns with top surface of sleeve (3).

2 . Bushing (2463, 7HEL054

and 7HEL354 kits)

f. Install hand wheel (26, figure 1-13) in

3 . Sleeve (2484, 7HEL354

bottom end of arbor, insuring that it seats firmly

kit)

against bottom of bushing (2, figure 4-40). Hoist

4 . Sleeve setscrew

entire assembly approximately inch off work

5 . Rotor hub assembly

stand. Check to insure that suspended assembly is

6. Balancing arbor (2259,

free from interference with work stand and other

7A050 kit)

objects, and note balance condition.

7 . Arbor scale

CAUTION

Figure 4-40. Balancer Installation - CH-47

In using available shop hoist for

Helicopter Rotor Head Assembly.

suspending rotor head assembly, care

should be exercised to avoid excessive

acceleration loading (jerking) of the

arbor suspension rod.

g. For balance tolerances and application of

balance corrections, refer to applicable helicopter

manual. (Refer to appendix A).

4-66

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |