|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-201-14

a. Assemble the hoist support structure except

use part no. 2769 tube assembly in place of the part

no. 2288 tube.

b. Center fixture (1, figure 4-19) on stand

table assembly (1, figure 1-13).

c. Install sleeve (2) over top of fixture (1) and

seat sleeve on upper shoulder of fixture's central

projection.

d. Install adapter (3), heavy end downward,

over top of fixture (1) and seat on top of sleeve (2).

Lock adapter in the position by tightening adapter

set screw (4) using 1/8-inch hex wrench (7A050,

7HEL054, 7HEL061 kits).

e. Carefully lower rotor hub assembly (8) over

fixture (1), aligning inside diameter of splined

trunnion with piloting diameter of adapter (3), and

insuring that cone surface of splined trunnion seats

firmly on cone surface of adapter (3).

f. Install pitch positioning locks. These are

available as manufacturer designed, Bell tool no.

T101402. Install carefully, and adjust blade grips

to symmetrical pitch positions. To accomplish this,

place a bevel (bubble) protractor on flat top surface

of rotor hub, across the grip pitch axis; adjust

protractor to center the bubble. Transfer

protractor, keeping it in same transverse position,

to bottom inside surface of either blade grip fork

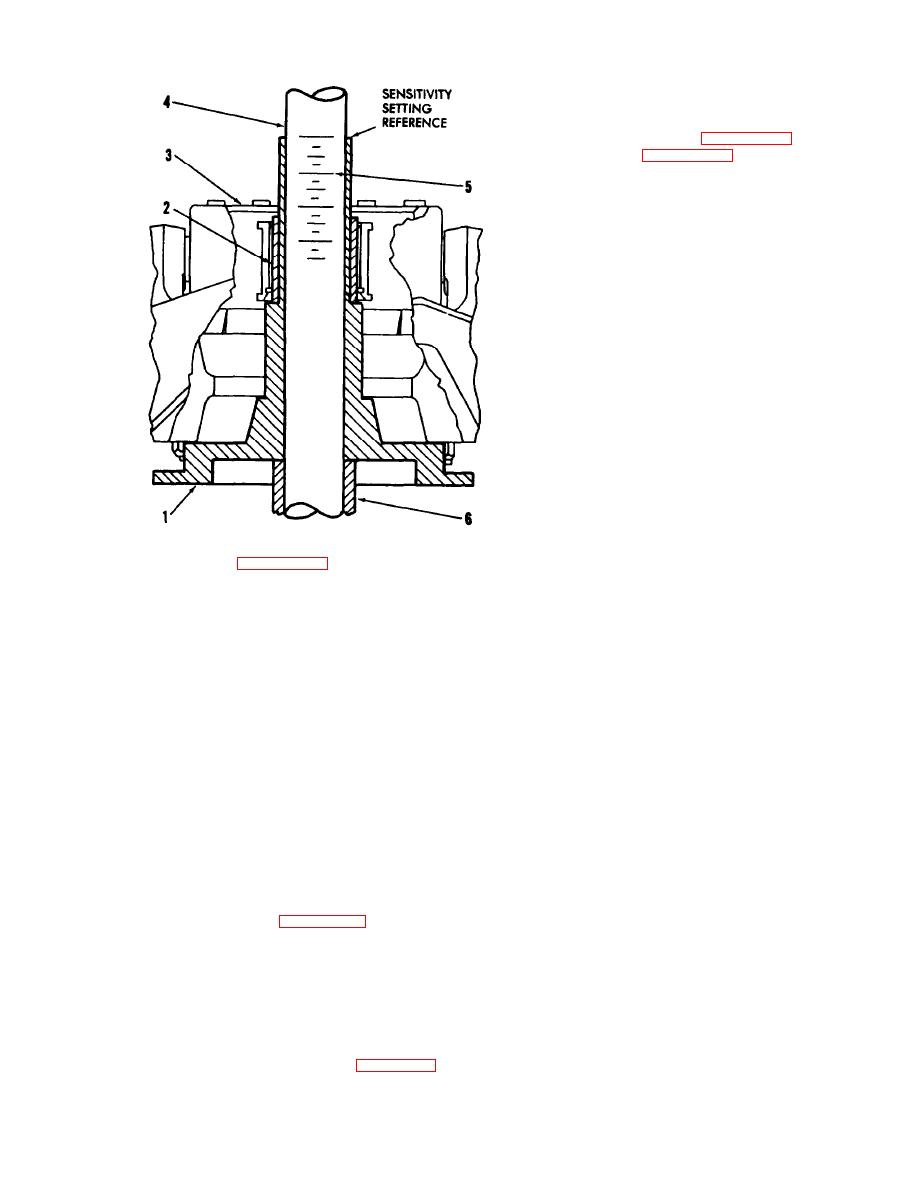

Key to figure 4-18:

and align protractor base with the transverse milled

1. Fixture (2337, 7HEL054

line in the fork surface. Adjust grip pitch only to

recenter the protractor bubble. Transfer protractor,

kit)

in same transverse position, to opposite grip fork

2. Sleeve (2467, 7HEL054

and repeat grip pitch adjustment. Repeat grip

kit)

pitch adjustment operation if necessary.

3. Rotor hub and blade

assembly

g. Using raw-hide or rubber mallet, tap heads

4. Balancing arbor (2259,

of rotor blade retention bolts in radially outward

7A050 kit)

direction to insure blade grips are fully seated in

5. Arbor scale

their radially outward positions.

6. Spacers (7A050 kit)

h. Install yoke (5), legs downward, on arbor

Figure 4-18. Balancer Installation - OH-13 and

(6) and position so that top surface of its locking

collar (sensitivity setting reference) aligns with

TH-13 Helicopter Main Rotor Hub and

arbor scale (7) listed below. Lock yoke (5) firmly in

Blade Assembly.

this position on arbor with its collar clamp screw.

using 3/16-inch hex wrench (7HEL061 kit).

4-36. UH-1

Helicopter.

(1) UH-1A:

4-37. UH-1

(Series A, B, D, F, H and N Typical

With Counterweights

15-1/2 inch

Main Rotor

Hub Assembly Balance Check (Except

(2) UH-1B, D, F, H & N:

540 Series

Hub). (See figure 4-19.)

Without Counterweights 14-3/4 inch

With Counterweights

14-1/2 inch

NOTE

i. Install arbor (6) downward through rotor

Additional hoist arm support height is

trunnion and fixture (1) assembly, seating both

required for this balance application. To

yoke (5) legs firmly on flat top surface of rotor hub,

provide this additional arm height, use

in line with blade grip pitch axis.

miscellaneous component tube assembly,

j. For UH-1A, install part no. 2202 spacer (9)

part no. 2769 in lieu of the part no. 2288

over lower end of arbor (6). For models UH-1B, D,

vertical tube (no. 4) shown in figure 3-3.

4-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |