|

|||

|

|

|||

|

Page Title:

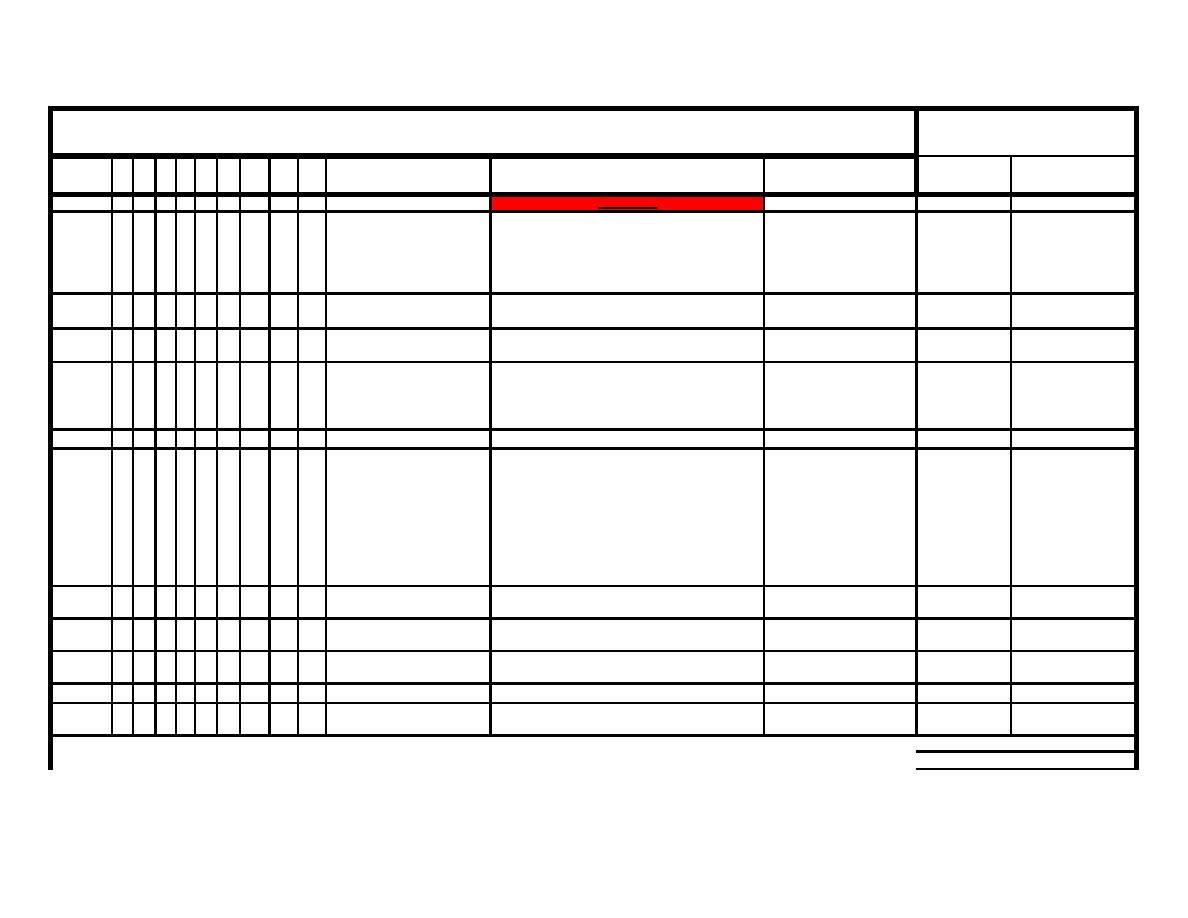

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

WARNING

DO NOT USE HAND BITS WHICH HAVE A

SCREW TIP. AT DRILL PRESS SPEEDS THEY

TURN INTO THE WOOD SO RAPIDLY AS TO

LIFT THE WORK OFF THE TABLE AND WHIRL

IT.

In changing the speed, turn off the switch and wait

until the machine has completely stopped.

Remove the chuck key before starting the motor.

Never use your hand to hold object while drilling,

always screw the object tight on the working table

or use the drill press vise to prevent an accident

or injury.

Keep your hand off the drill bit while drilling.

Do not operate

Replace worn or frayed

X

Belt and Pulley

Check for worn or frayed belts, frayed electrical

equipment if

belts, repair frayed

wiring or power cord, loose connections, missing

belts are worn,

electrical cords, loose

bits and pieces, worn or damaged pulleys, dirt

frayed, or

connections or damaged

buildup and corrosion.

electrical

pulleys. Clean as

connections and

necessary.

wiring are

unserviceable.

X

Check that spindle and motor pulleys are tight and Tighten as necessary.

secure.

X

Table/Crank

Check that table vertical travel is smooth and

Repair as necessary.

unobstructed.

X

Check that 360 degree table swing is

Remove obstructions.

unobstructed.

X

Check that table tilts in either direction.

Repair as necessary.

X

Spindle

Check that spindle vertical travel is smooth and

Remove obstructions.

unobstructed.

LSV PMCS

Change 12

2-292

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |