|

|||

|

|

|||

|

Page Title:

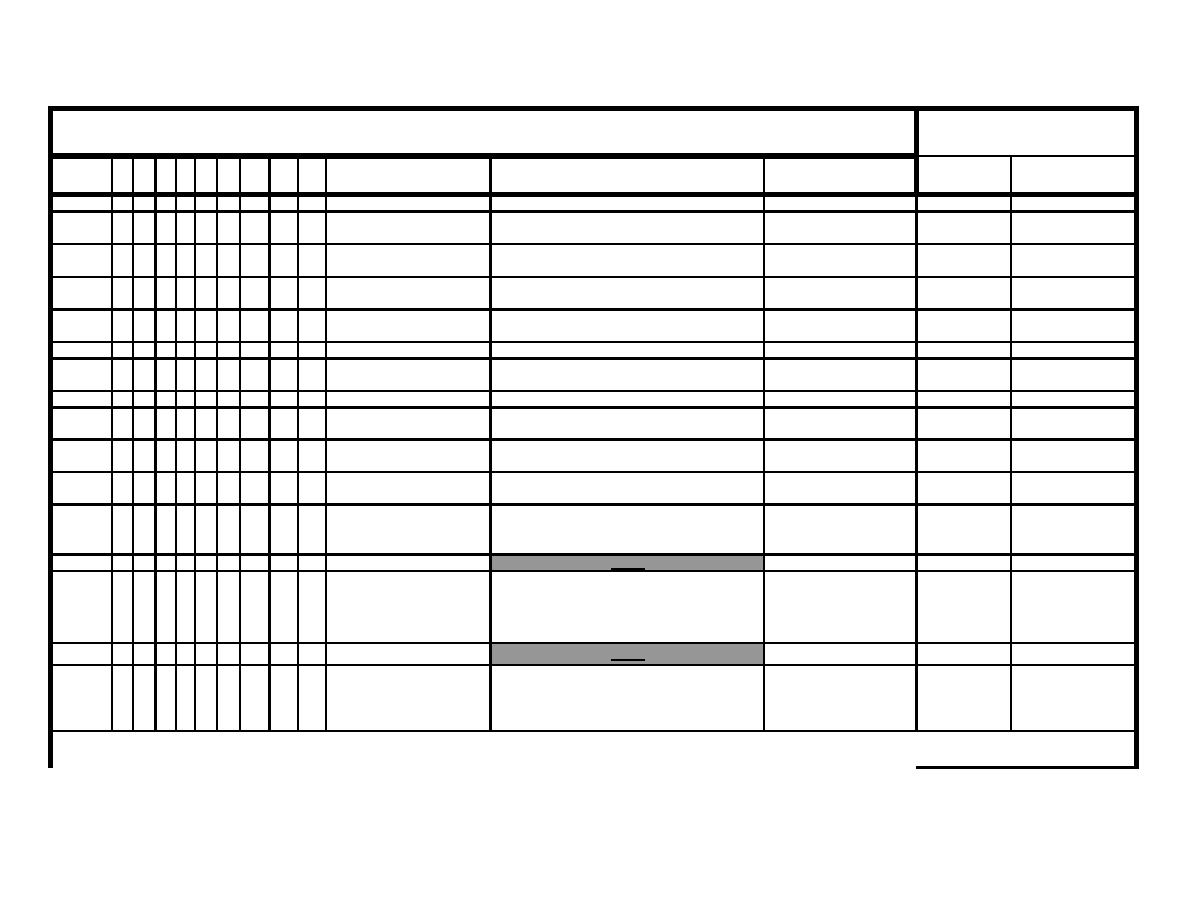

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

65

Gyro Compass

X

Follow-up Alarm Lamp

Check that light is off.

Troubleshoot, repair as

Power loss to

necessary.

compass.

X

Caged Lamp

Check that light is off.

Troubleshoot, repair as

necessary.

X

Latitude Control

Check that control is set at local latitude.

Set control in proper

position.

X

North-South (N-S) Switch

Check that switch is set is set at proper latitude.

Set switch in proper

latitude.

X

Level Meter

Normal settled tilt indication.

X

Azimuth Card Reading

Check that azimuth reading is within two degrees

Refer to unit maintenance

when settled.

for repair.

X

Card Window

Check for cleanliness

Clean as necessary.

X

Fluid Level Viewed in Window Check that fluid has no bubbles present.

Troubleshoot and repair as

Bubbles are present.

required.

X

Master Compass

Check for oil seepage around any seam or seal.

Troubleshoot and repair as

Oil Seepage.

required.

X

Shock Mounts

Check that binnacle moves freely in its shock

Free mounts.

mounts.

X

Check spare parts and equipment belonging to

Clean as necessary.

66

Tools, Spare Parts and

the craft are clean, serviceable and properly

Properly stow.

Equipment

mounted and/or stowed.

NOTE

Before performing preventive maintenance checks

and services, review appropriate procedures to

ensure that necessary tools, spare parts and

equipment are available.

NOTE

Upon the completion of preventive maintenance

checks and services, inventory all tools, repair

parts and equipment to ensure proper

accountability.

LSV PMCS

Change 12

2-282

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |