|

|||

|

|

|||

|

Page Title:

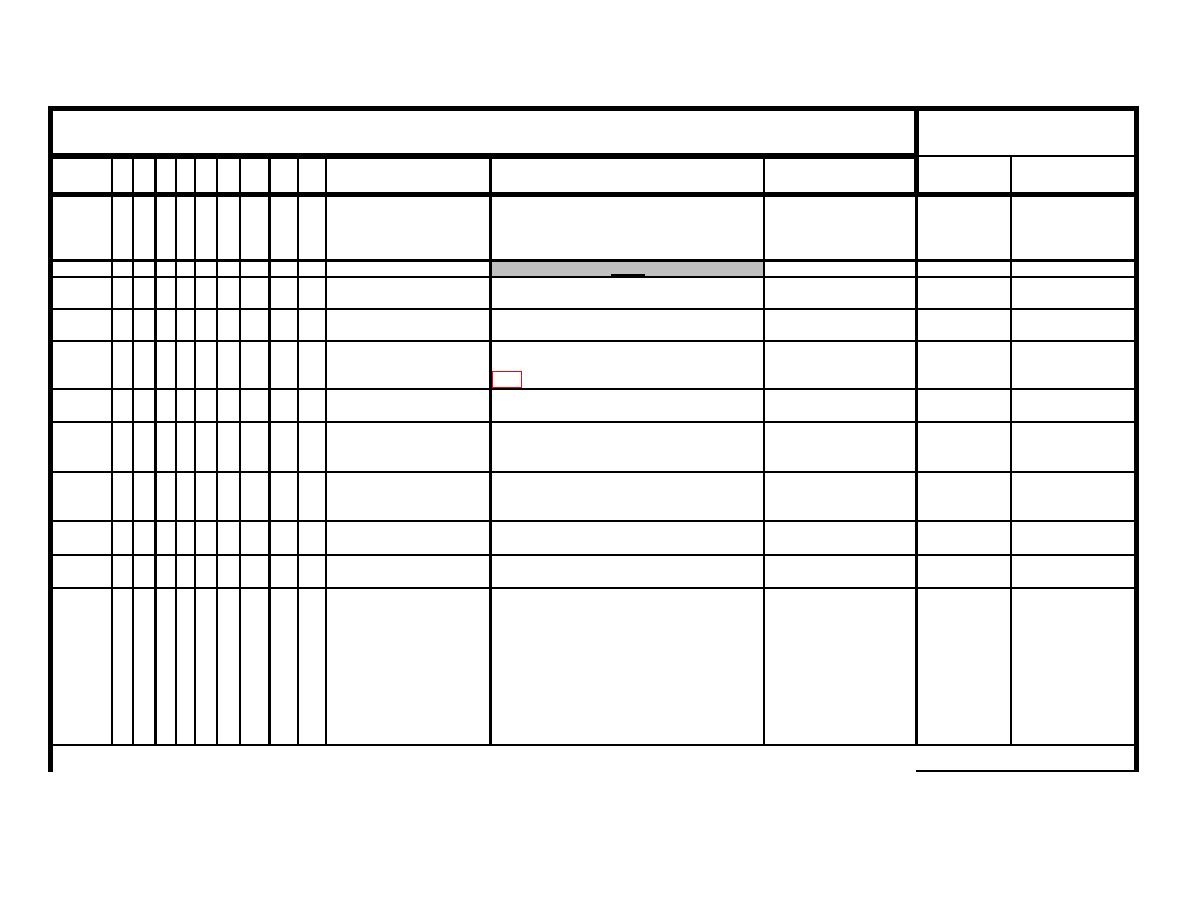

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

Check cooling water expansion tank level on tank Add coolant as necessary. Temperature

X

Cooling System

above 195

Troubleshoot, repair as

sight glass indicator. Check gauge for proper

degrees F.

necessary.

operating coolant temperature (170 to 195

Degrees F).

NOTE

Expansion tank level should be slightly less than

full to allow for expansion.

X

X

Leaks

Check for fuel leaks, oil, coolant leaks and

Repair leaks. Troubleshoot Class III leaks or

unusual noises.

and repair noise.

unusual noises.

Place switches in proper

X

Switches

Check that all switches are in proper positions.

position.

Refer to Chapter 2, Section I, Table 2-1, Figure

X

Compare tachometer indications to standard bow

Troubleshoot, repair as

thruster operations.

necessary.

Low oil level.

X

X

Check oil level in lube oil tank. Check machinery

Add oil as necessary.

62

Bow Thruster

oil for leaks.

Investigate and repair oil

leaks.

Add oil as necessary.

X

Check marine gear oil level on oil level dipstick.

Level should be between the add and full marks

on the dipstick.

X

Service Hour Meter

Check the indicated number of hours the engine

Record reading in the

has been operated.

engine historical data log.

X

Check operation of wipers.

If blades streak,

63

Clearview

repair/replace.

X

X

Check heading on two known courses. Check

Magnetic compass is

Remove bubbles in bowl,

64

Magnetic Compass

deviation whenever metal structural changes are

inoperative. Compass

update deviation card as

made to vessel; or when electronic equipment is

will not swing freely in

necessary.

gimbals.

added/removed. Check that deviation card is up to

date and annual deviation is posted. Ensure

deviation card is located in the immediate vicinity

of the compass.

LSV PMCS

Change 12

2-281

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |