|

|||

|

|

|||

|

Page Title:

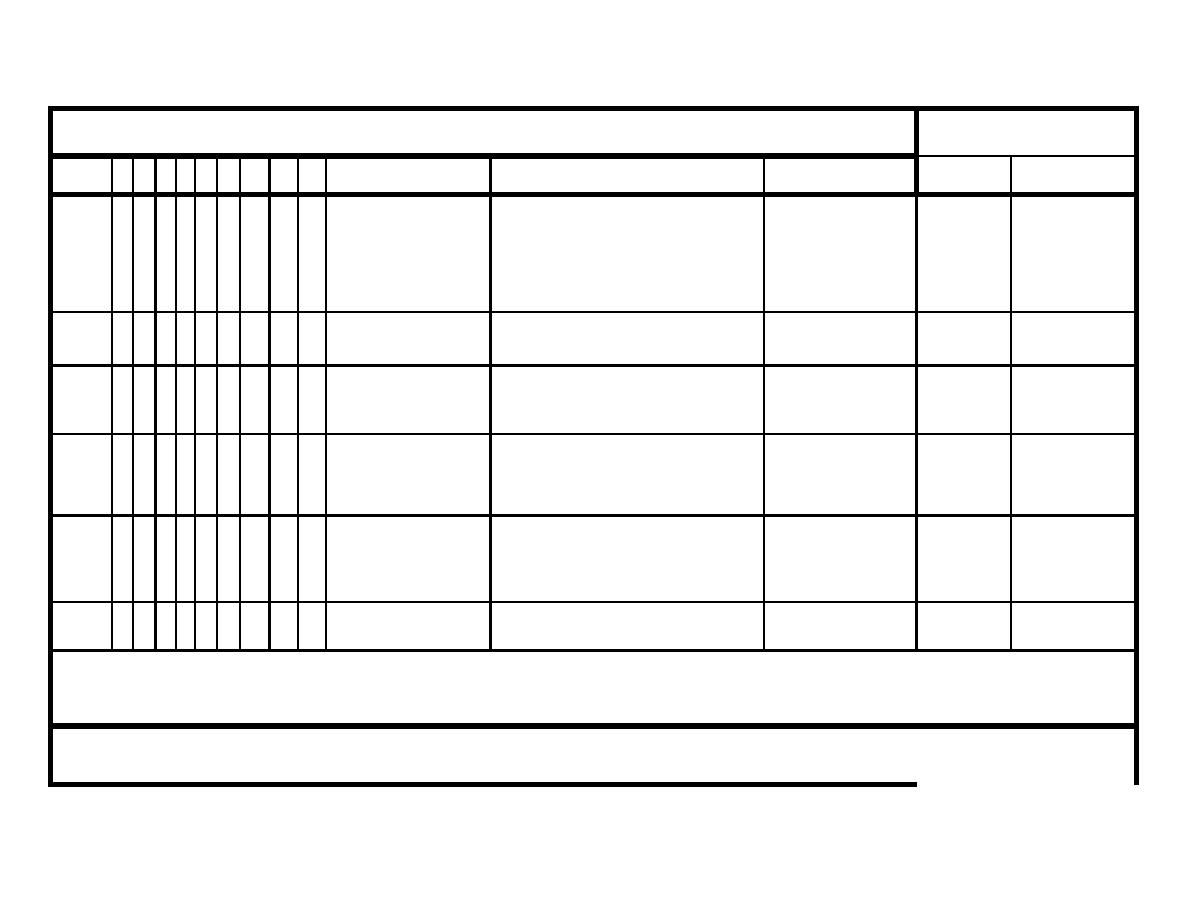

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

21

FM-200 Fixed Fire

Suppression System in the

Engine Room, Bowthruster

Room, Paint Locker, and

IF EQUIPPED

Emergency Generator

Room

X

FM-200 Cylinder Pressure

Check pressure gauges for proper operating

Refer to general support

Cylinder pressure

pressure. For proper operating pressure, the

(GS) maintenance to have

gauge indicator not in

gauge should be in the GREEN area.

cylinder recharged.

the GREEN area

Cylinder liquid level

X

FM-200 Cylinder Liquid Level Ensure liquid level readings are taken IAW

If liquid level is low, refer to

general support

low.

appropriate manufacturer's manual supplied

maintenance to have

with as-built manuals/drawings.

cylinder recharged

X

Complete FM-200 System

Refer to general support

Damaged components

Inspect system components IAW appropriate

maintenance for repair or

to extent to prevent

manufacturer's manual supplied with as- built

service of damaged

FM-200 system

manuals/drawings.

components

activation

X

Ventilation Dampers and

Operate and remove access covers and service Repair/replace dampers as

Dampers not

Closures.

engine room supply air dampers (Port and

necessary.

operating to extent to

prevent area closure

Starboard) and engine room exhaust air dampers

for function of FM-200

(Port and Starboard).

system.

X

Steering Gear Compartment Operate door to verify operation IAW

Perform maintenance IAW

Sliding Watertight Door

manufacturer's manual.

manufacturer's manual

LSV PMCS

Change 12

2-261

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |