|

|||

|

|

|||

|

Page Title:

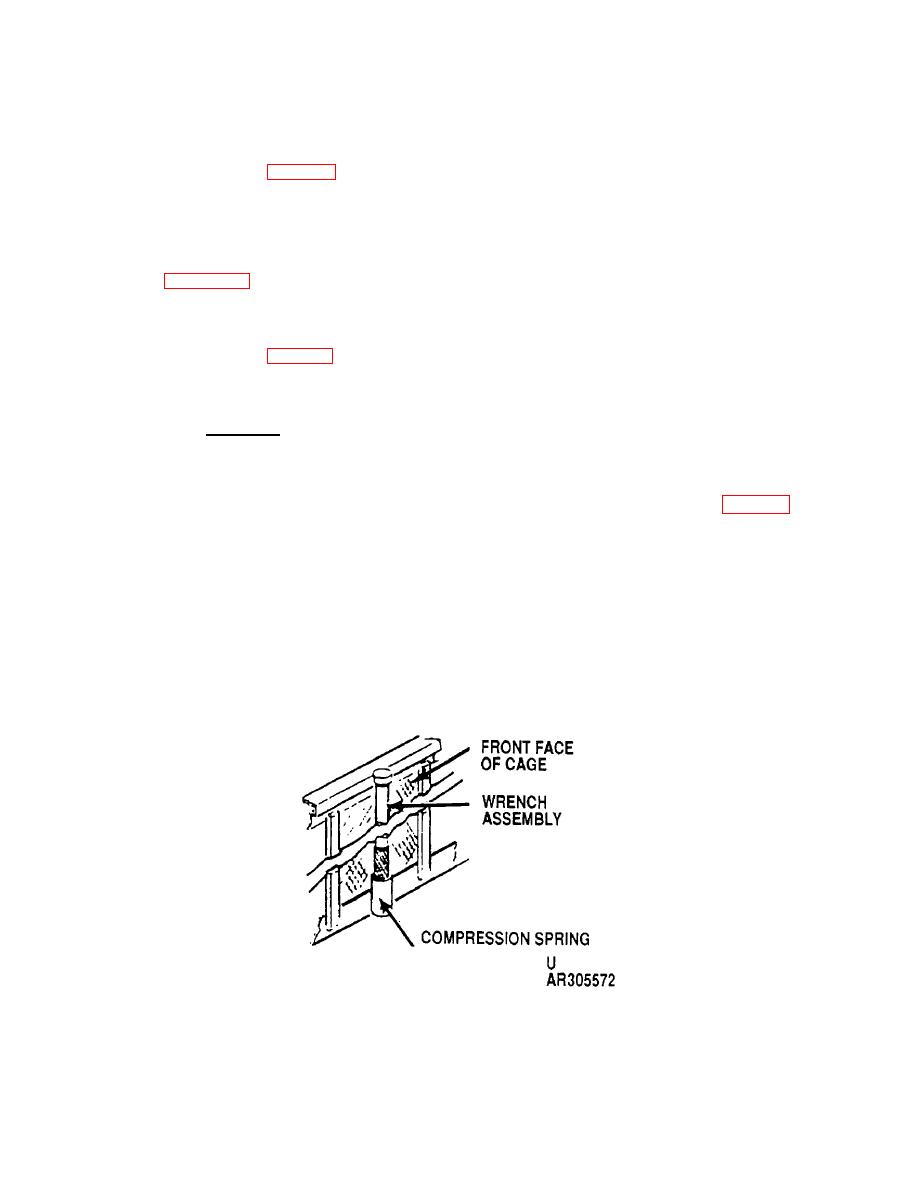

Figure 1-3. Wrench Retaining Assembly |

|

||

| ||||||||||

|

|

TM 9-8140-381-14&P

tow bar length and the other two casters should be free

1-5.3. All casters may be swiveled to position the wheel

in the desired direction as follows:

to swivel (unlocked).

1-5.4.2. Towing on site with a tow bar shall be limited to

a. Unlock swivel mechanism by pulling outward on

distances not greater than 2 miles at speeds not to

spring-loaded wire ring (fig. 1-2) until it is clear

exceed 5 miles per hour. Towing may be performed

of the deep recess in the swivel lock housing

with or without contents installed. There is a tow hitch

and rotate ring a quarter-turn until it snaps into

on each side with the tow bar attached with a quick

the shallow recess of the housing.

release pin.

b. Rotate caster using caster fork assembled to T-

1-5.4.3. When moving the WSC up or down an incline,

handle (par. 1-5.5). Caster fork is placed

the two casters on the opposite side from the direction

around caster wheel.

of travel should have their swivels locked with the

wheels parallel to the travel direction; the other two

c. Lock swivel mechanism by pulling outward on

caster swivels should be unlocked.

spring-loaded wire ring (fig. 1-2) and rotate ring

a quarter-turn until it snaps completely into the

1-5.5. Caster Fork Wrench Assembly

deep recess of the swivel lock housing.

Instructions.

WARNING

a. Remove caster fork from its storage bracket by

DO NOT FORK LIFT WSC FROM

removing quick release pin.

FRONT SIDE.

b. Push T-handle with clamp tool toward bottom

1-5.4. The WSC may be moved with or without

edge of front face of cage (fig. 1-3) until top of

contents installed for short distances by pushing it using

T-handle clears the upper retaining cap. This

four persons, or between structures within a single

will be caused by the force of the spring that is

storage area by means of a forklift using the designated

captured in the lower retaining cap. Lift and

forklift points, or by means of the tow bar.

remove T-handle from lower retaining cap. The

clamp should remain assembled.

1-5.4.1. When moving the WSC with the tow bar, the

swivel locks of the two casters on the side opposite the

c. Slip caster fork over T-handle and secure with

tow bar should be locked with the wheels parallel to the

quick release pin.

Figure 1-3. Wrench Retaining Assembly

1-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |