|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-4940-544-14&P

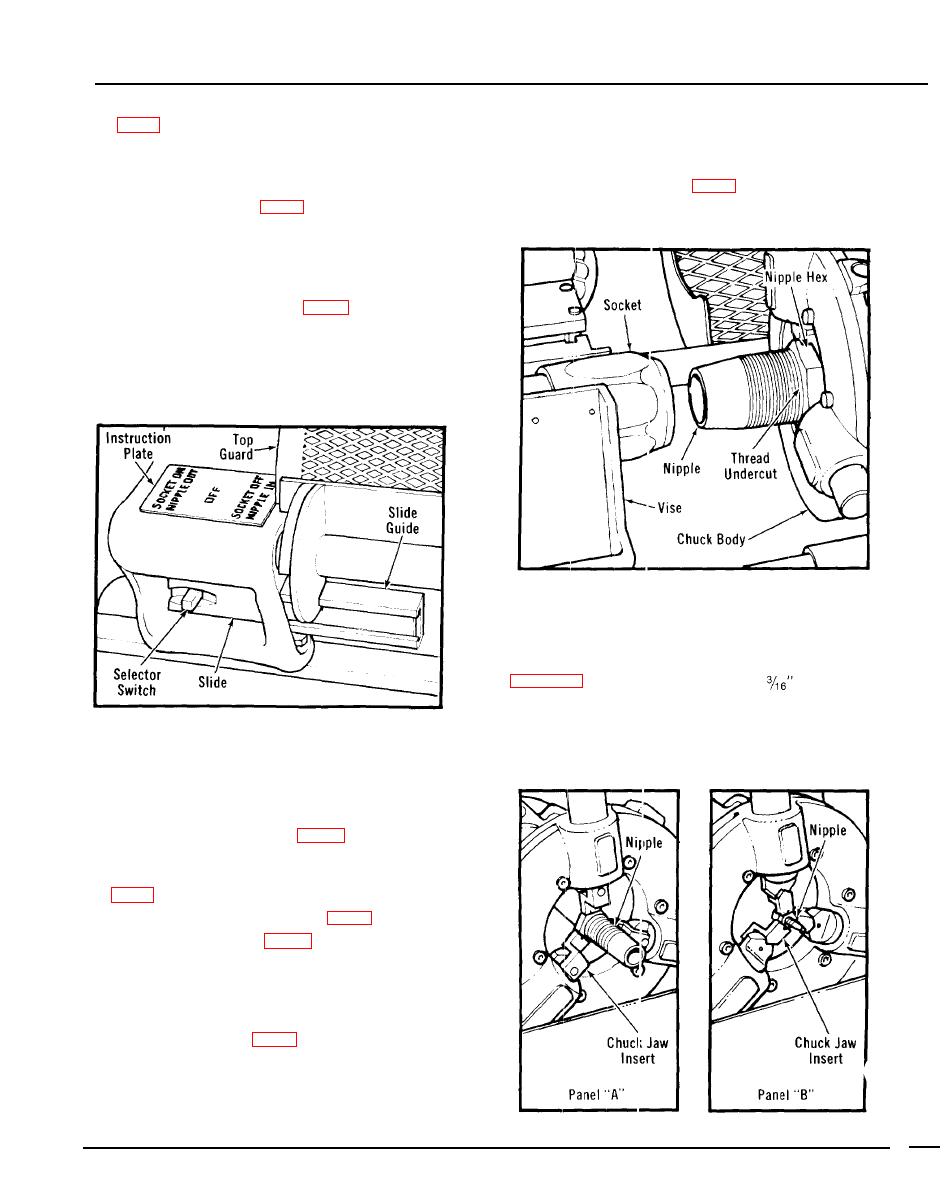

5. Flip Selector Switch to "SOCKET ON" position

8. Push on Vise Carriage to start socket on

nipple.

Note: To disassemble socket from hose move

9. Release Foot Switch when socket starts to

S e l e c t o r Switch to "SOCKET OFF"

cross thread undercut and allow socket to

position.

coast up to nipple hex (Fig. 6).

6. Step on Foot Switch (Fig. 1).

Important: Never bottom socket against nip-

ple hex with power on.

Important: Never reverse Selector Switch and

step on Foot Switch until chuck has

completely stopped to prevent dam-

age to Motor.

7. Push on Vise Carriage (Fig. 4) to start hose

into socket.

8. Release Foot Switch when hose is assembled

to socket.

9. Loosen Vise and Chuck and remove socket

with hose.

Chuck Jaw Inserts

Position Chuck Jaw Inserts as shown in Panel "B",

through 1".

For smaller size bent tube nipples position Chuck

Jaw Inserts as shown in "A" or "B" as required.

Larger bent tube ends do not require use of Chuck

Plate.

Jaw Inserts.

Assembling Nipple to Socket

1. Apply lube to end of nipple and inside of hose.

2. Install Chuck Jaw Inserts, if required.

3. Clamp nipple in chuck (Fig. 6) using Chuck

Wrench.

4. Remove Chuck Wrench and close Top Guard

5. Clamp socket with hose in vise (Fig. 6).

6. Flip Selector Switch (Fig. 5) to "NIPPLE IN"

position.

Note: To disassemble nipple from socket flip

Selector Switch to "NIPPLE OUT"

position.

7. Step on Foot Switch (Fig. 1).

Important: Never reverse Selector Switch and

step on Foot Switch until chuck has

completely stopped to prevent dam-

age to motor.

9

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |