|

|||

|

|

|||

|

Page Title:

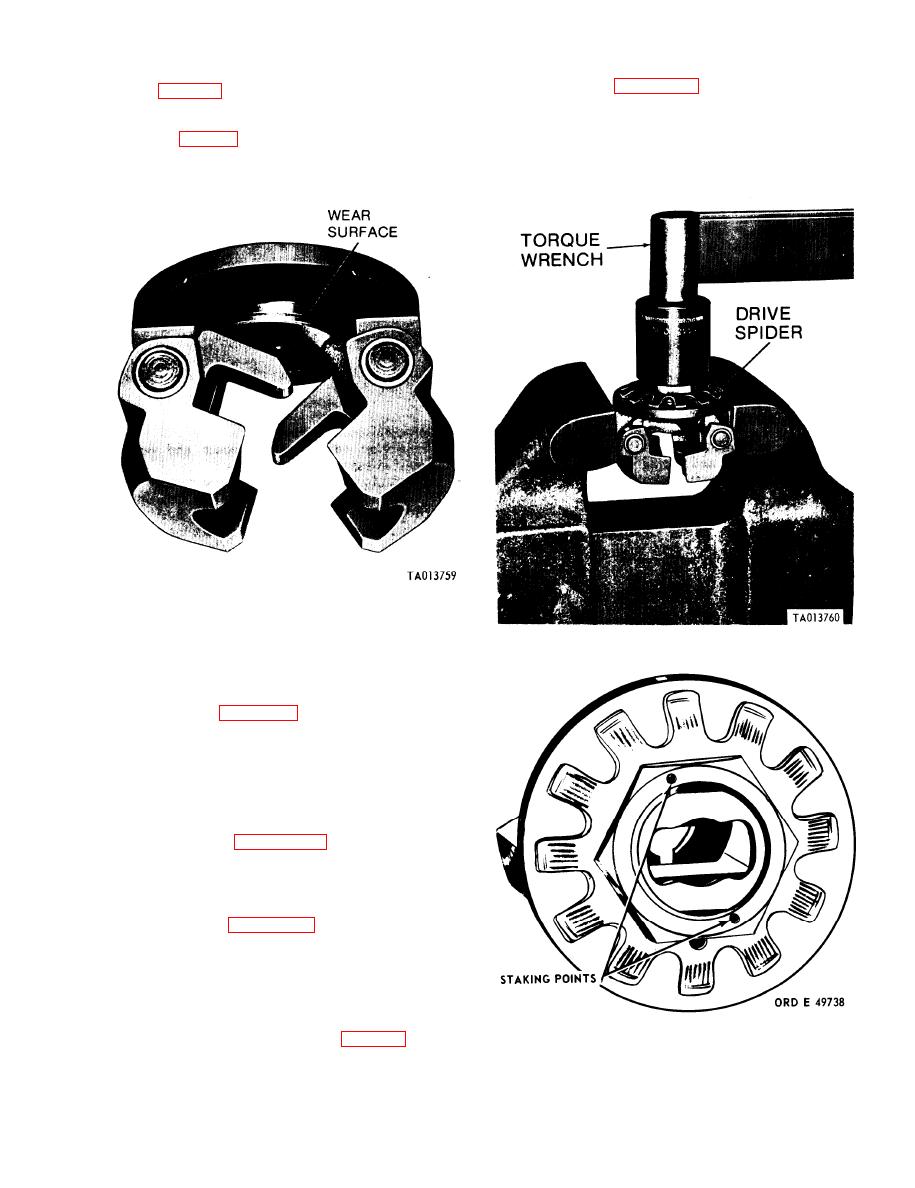

Figure 3-92. Inspecting friction drive spider wear surface. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

(4) Refer to figure 3-94. Using a center punch,

and D, fig. 3-91) and the mating surface on the

stake spring disk adjusting nut at two points in-

friction drive spider for evidence of wear or damage.

dicated to prevent nut from loosening.

(2) Carefully inspect the mating surface of the

(5) Remove friction drive spider and governor

drive hub (fig. 3-92) and spider for evidence of wear

assembly from vise.

or damage.

Figure 3-92. Inspecting friction drive spider wear surface.

(3) If damage or wear is evident on any part,

replace the complete assembly. Retain the weight

Figure 3-93. Checking friction drive spider slippage.

and spider assembly for possible repair.

c. Assembly. Assemble the governor weight and

spider assembly as follows:

(1) Refer to figure 3-91. Install retainer (if used),

0.035-inch spring disk spacer (E), inner spring disk

(D), 0.035-inch spring disk spacer (C), outer spring

disk (B) and nut (A).

NOTE

The outer spring disk contains an iden-

tification hole to distinguish it from the inner

disk.

(2) Refer to figure 3-90. Position governor

weight assembly in vise using 3/8 x 3/4-inch steel

bar stock as shown. Tighten hub nut to 80-85

foot-pounds. Remove friction drive spider and

governor weight assembly and bar stock from vise.

(3) Refer to figure 3-93. Install friction drive

spider and governor weight assembly in vise

equipped with soft metal jaws as shown. Lubricate

the spring disk bearing surface with engine oil and

take a running torque reading. Torque reading

should be between 48 and 72 inch-pounds. If the

torque reading falls below these limits, install a

thinner spring disk spacer (E, fig. 3-91). If the

Figure 3-94. Staking spring disk adjusting nut.

torque reading exceeds these limits, replace the

governor weight and spider assembly.

3-59

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |