|

|||

|

|

|||

|

Page Title:

Needle Valve Tip Test-continued |

|

||

| ||||||||||

|

|

TM 9-2815-224-34&P

Fuel Injector Maintenance Instructions (Cont)

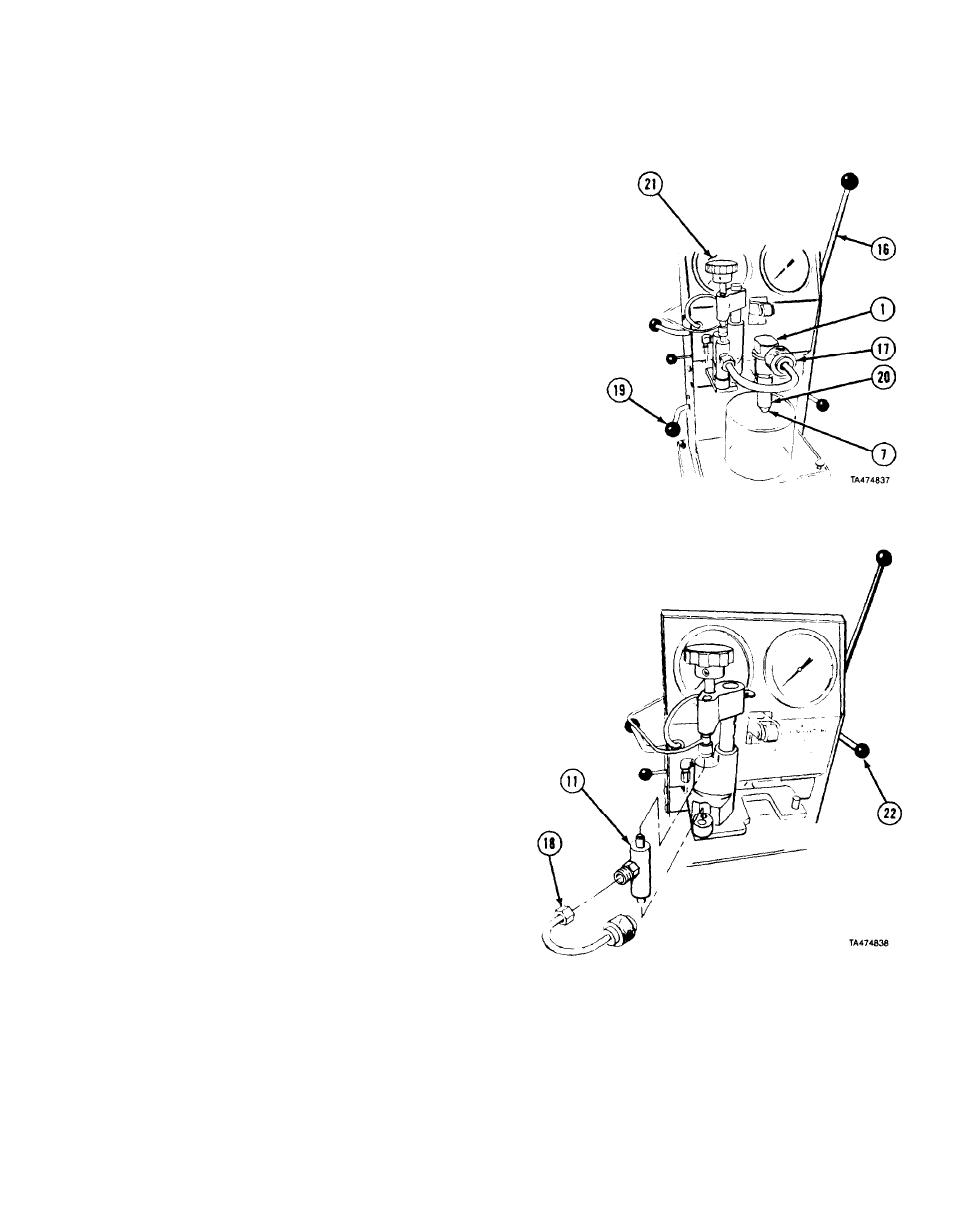

(15) Position valve lever (19) so it points down.

(16) Pull pump lever (16) forward 40 to 80 times a

minute with steady strokes and watch oil spray

pattern from tip of injector (20).

( 1 7 ) If injector (20) does not spray oil evenly in a fine

mist, disassemble injector and inspect for

( 1 8 ) Check left gage (21) to find pressure that causes

injector (20) to spray. If injector spray pressure is

less than 2200 psi (15 169 kPa) or more than

3300 psi (22 753 kPa), disassemble injector and

inspect for contamination or damage.

(19) Move pump lever (16) forward several times slowly

to let pressure build up to 1500 psi (10 335 kPa) on

left gage (2 1). Keep moving lever (16) as needed to

keep pressure at 1500 psi (10 335 kPa) for

15 seconds.

(20) Check injector tip (7) for signs of leakage or oil

droplets. Slight wetting of tip is all right, but if tip

leaks or if there are drops of oil present,

disassemble injector, clean and reassemble.

(21) Loosen coupling nut (17) slowly to allow release of pressure and remove tip test adapter (1).

(22) Move clamp release lever (22) down.

(23) Remove oil flow adapter (11) and

tube (18). Disconnect adapter from tube.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |