|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Engine Block Maintenance Instructions (Cont)

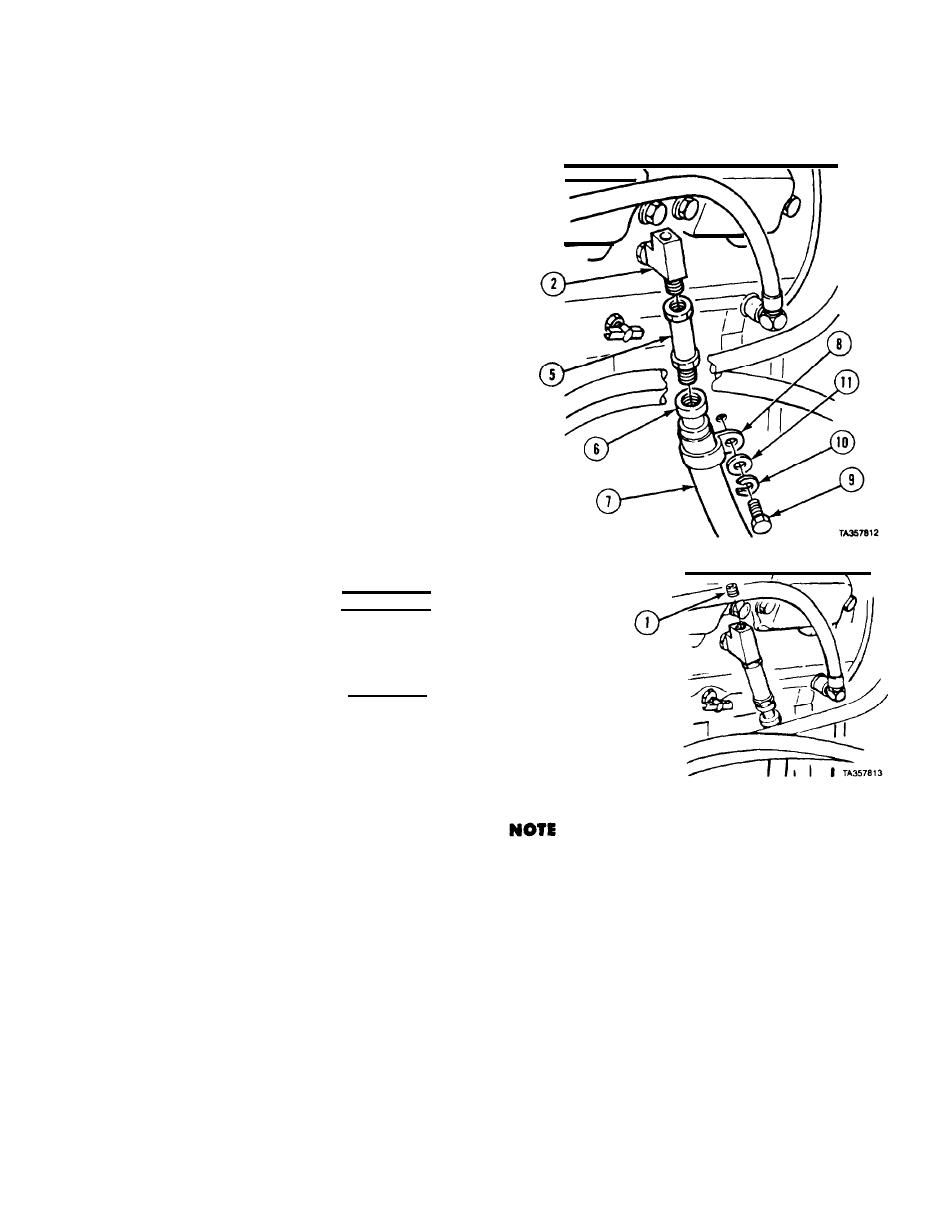

(4) Install check valve (5) on tee (2).

(5) Install fitting (6) and hose (7) on check

valve (5).

(6) Install clamp (8) with screw (9),

lockwasher (10), and washer (11).

c. Testing Air Flow.

WARNING

Do not stand in front of vehicle when testing airbox

pressure. Brake could release and vehicle could jump

forward causing personal injury or death.

CAUTION

Do not operate vehicle with transmission engaged and at

maximum rpm for more than 15 seconds at a time.

Transmission oil heats up quickly and could cause

transmission to fail.

(1) Remove plug (1) and install air pressure gage.

(2) Chock wheels, set parking brake and foot brake (TM 9-2320-279-10).

Low airbox pressure can be caused by an obstruction in the air inlet system, dirty

or damaged air cleaners, damaged blower rotors, or an air leak from the airbox

(such as leaking end plate gaskets). High airbox pressure reading can be caused

by partially plugged cylinder liner ports.

(3) When told by Soldier A, Soldier B starts engine (TM 9-2320-279-10), warms up engine for

5 minutes, then shifts transmission into Drive (D).

(4) Check airbox pressure. Pressure shall be 9 psi (62 kPa) at 1200 rpm, 16 psi (110 kPa) at 1800 rpm

and 20 psi (138 kPa) at 1950 psi.

d. Follow-on Maintenance.

(1) Stow spare tire (TM 9-2320-279-10).

(2) Connect batteries (TM 9-2320-279-20).

END OF TASK

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |