|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

CRANKSHAFT AND GEARCASE BACKPLATE REPAIR (CONTINUED)

CLEANING

NOTE

WARNING

Front and rear main bearings are available in

Dry-cleaning solvent used to clean parts is poten-

0.010- and 0.020-inch undersize.

tially dangerous to personnel and property. Do

not use near open flame or excessive heat. Flash

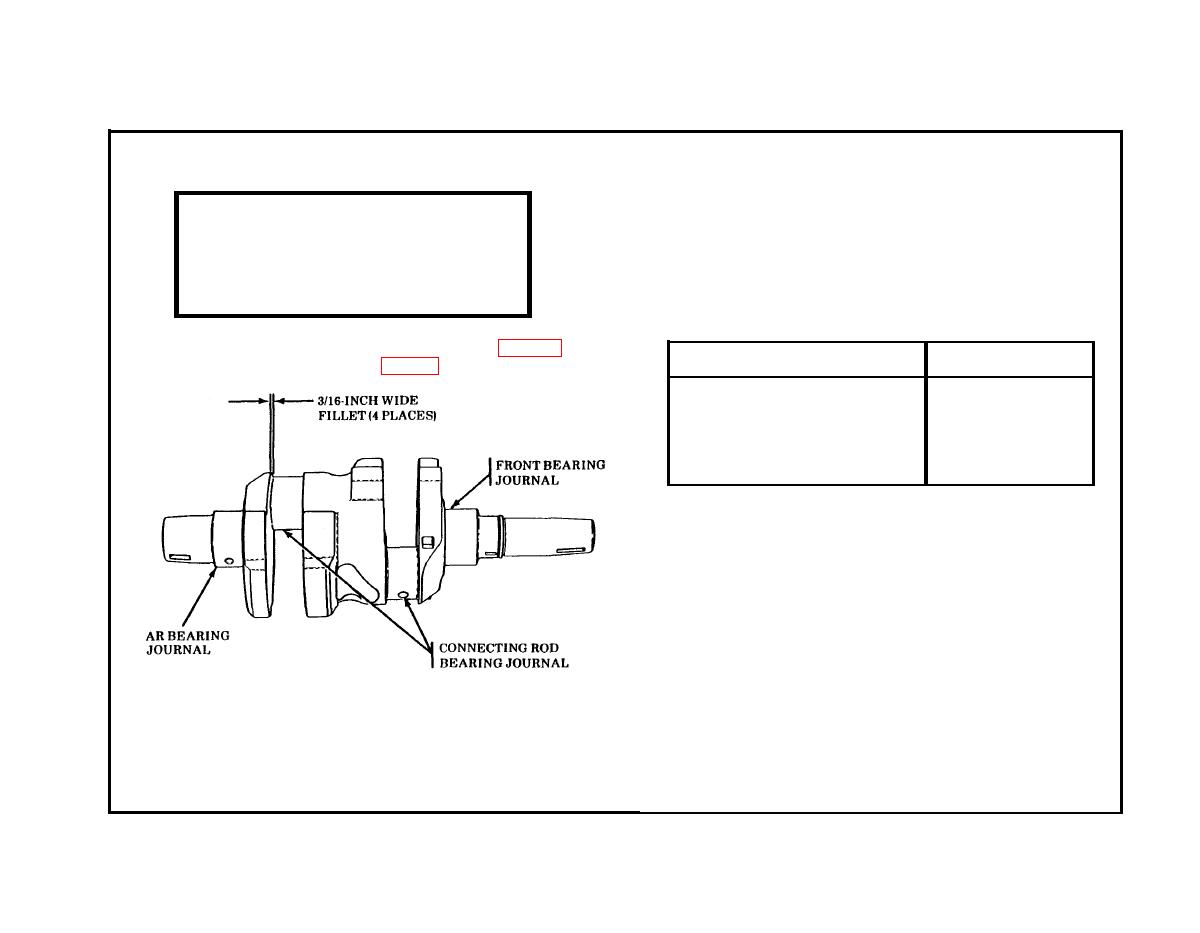

Inspect crankshaft journals for grooving, ridges, and scor-

B

point of solvent is 138F.

ing. Measure crankshaft at points listed in table below.

Clean crankshaft using dry-cleaning solvent (item 8, Appx C) or

WEAR LIMIT (Inches)

MEASUREMENT POINT

mineral spirits paint thinner (item 21, Appx C).

Connecting rod bearing journal

2.0582 min. dia.

Main bearing journal

2.2417 min. dia.

Crankshaft outer diameter

Out-of-round

0.001 max.

Taper

0.001 max.

Regrind crankshaft journals if journal diameters are not

C

within limits or if journals are scored, ridged, or grooved.

Regrind to next available undersize bearing size. Regrind or

polish to number eight finish.

If crankshaft has been reground, shot peen crankshaft

D

fillets after regrinding:

(1) Mask connecting rod bearing journals.

INSPECTION AND REPAIR

(2) Shot peen fillets for 30 seconds each, with shaft turning

at 15 rpm, using 0.019-inch diameter cast steel shot.

A

Inspect crankshaft for cracks using magnetic-particle in-

(3) Almen gage reading against shot-peened area should be

spection or dye-penetration method. Replace crankshaft if

cracked.

0.012A intensity per MIL-S-13165.

TA311233

TM 9-2815-221-34&P

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |