|

|||

|

|

|||

|

Page Title:

Section VII. Repair of Camshaft |

|

||

| ||||||||||

|

|

TM 9-2815-213-34

Section VII. Repair of Camshaft

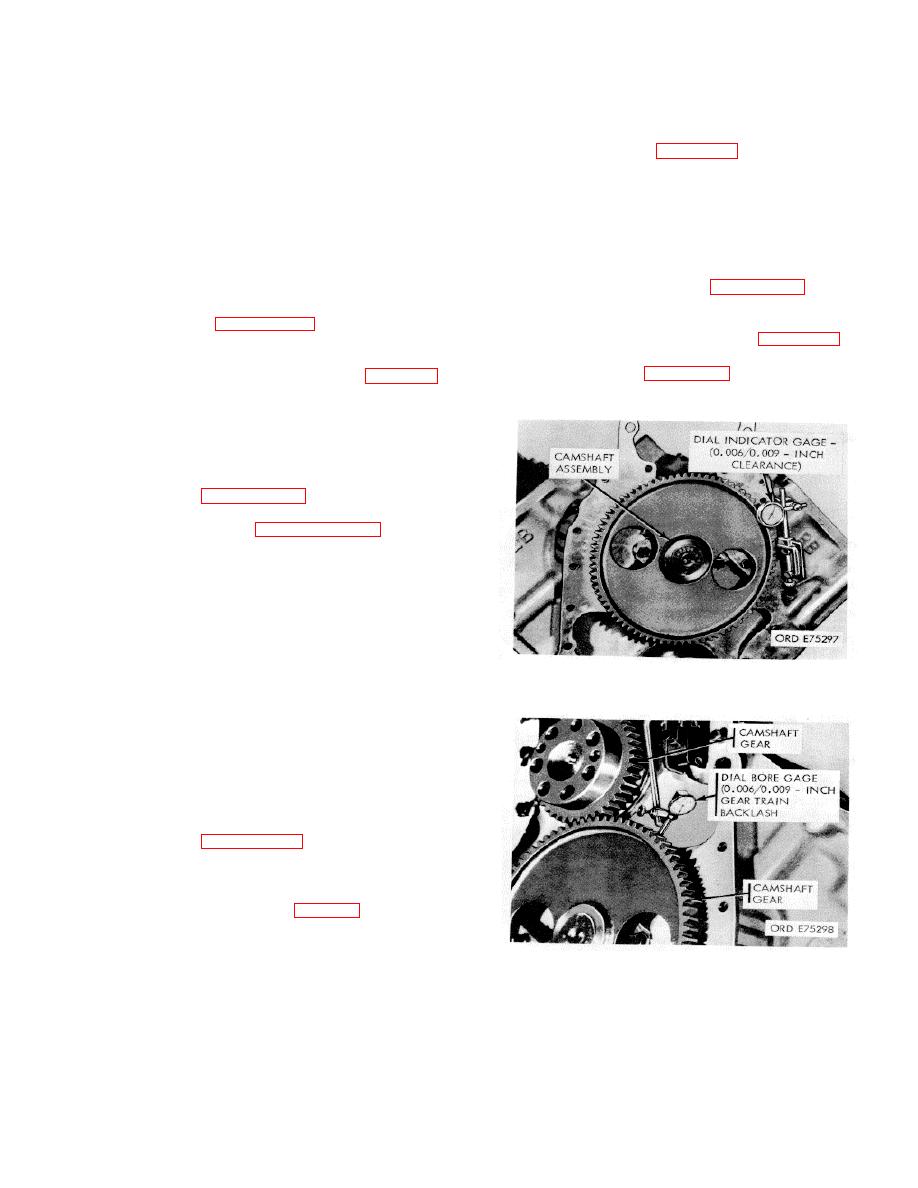

e. Check camshaft and clearance as follows:

3-30. Disassembly

(1) With a suitable holder attach a dial indicator

NOTE

to the block, as shown in figure 3-18, with indicator arm

Remove camshaft gear only if thrust

resting on face of gear teeth.

plate or gear is chipped, cracked or

(2) Push and pull on shaft several times.

visibly worn. If necessary to facilitate

(3) Push shaft in until shaft bottoms and set

removal, heat gear to 400 degrees F.

indicator to zero.

(4) Pull out oil shaft and note reading on

a. Place shaft in a suitable press between blocks and

indicator.

press off gear.

(5) Check reading against specified limits in

b. Remove key and thrust plate. Discard key.

repair and rebuild standards (para. 3-180). If end

3-31. Cleaning

clearance is not within limits specified remove camshaft

Clean camshaft and components in accordance with

and replace thrust plate.

instructions contained in paragraph 2-5

f. Attach dial indicator as shown in figure 3-19 and

3-32. Inspection

measure gear backlash against limits specified in repair

a. Check shaft journals and injector lobes against

and rebuild standards (para. 3-180). If backlash is not

specified limits in repair and rebuild standards paragraph

within specified limits replace camshaft gear.

3-180. Replace shaft if any measurement is outside limits

specified.

b. Check thrust plate against specified limits in

repair and rebuild standards, replace plate if limits are

exceeded.

c. Visibly inspect gear in accordance with general

inspection procedures, paragraph 2-6

d. Check gear diameter against specified limits in

repair and rebuild standards paragraph 3-180 Replace

gear if limits specified are exceeded

3-33. Assembly

a. Install key in place, red tip to rear of camshaft.

b. Coat camshaft thrust bearing with lubricating oil

OE10 and place thrust bearing on camshaft.

c. Coat gear hub area on camshaft with lubricating

oil OE-10.

d. Heat gear to 400 degrees Fahrenheit in oven or with

heating torch and press gear onto shaft

Figure 3-18. Camshaft end play check.

CAUTION

When using heating torch, heat gear

hub only. Do not direct flame at gear

teeth.

3-34. Repair

Repair of camshaft and gear is limited to general

procedures outlined in paragraph 2-7.

3-35. Installation

a. Lubricate lobes and journals with high pressure

grease.

b. Install camshaft in the block (fig. 2-24).

c. Index "0" mark on camshaft gear with "O" mark

on crankshaft gear to insure correct timing.

d. Secure camshaft thrust plate to block with

Figure 3-19. Crankshaft gear backlash check.

lockplates and capscrews.

3-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |