|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

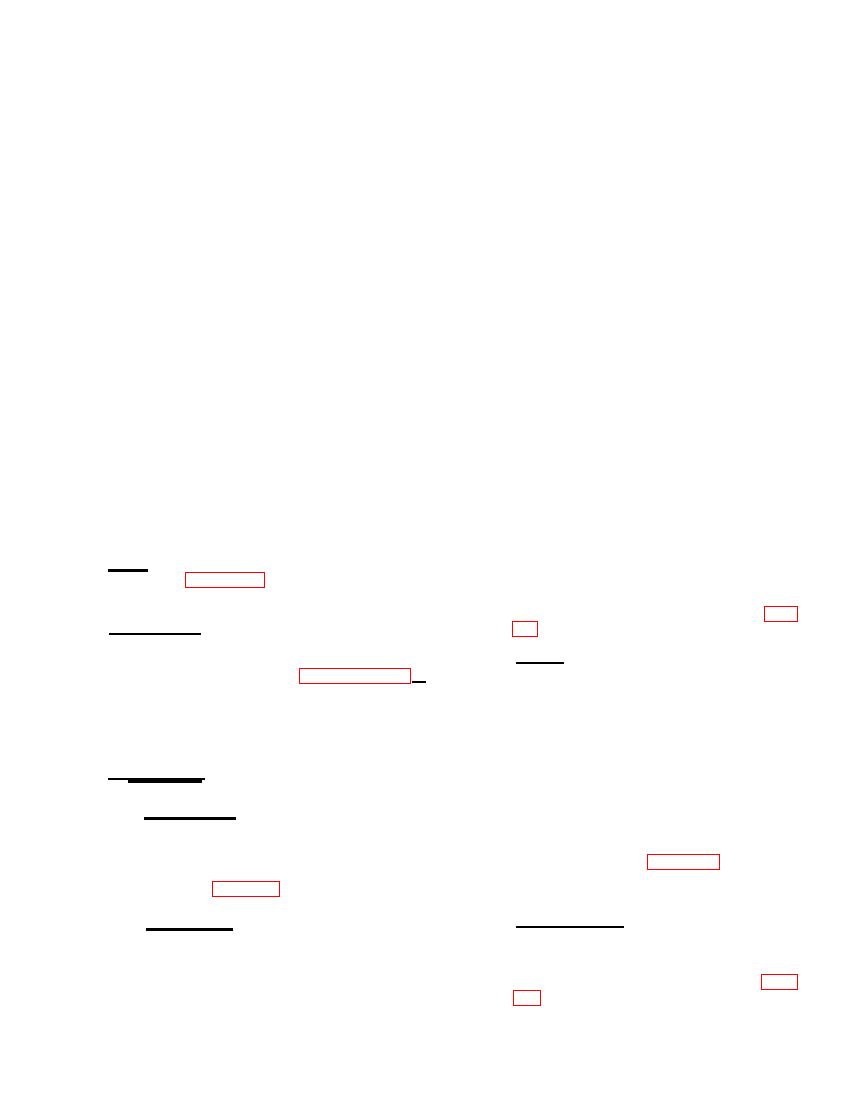

A - Retaining ring

9 - Intake and exhaust valve guide

B - Thrust washer

1 0 - l/8-in. pipe plug

c - Valve rocker arm assembly

1 1 - Core hole plug

1- Lock nut

1 2 - Exhaust valve seat

2- Rocker arm

1 3 - Exhaust valve

3- Rocker arm adjusting screw

1 4 - Intake valve

D - Core hole plug

1 5 - Intake valve seat

E - Rocker arm shaft

1 6 - Cylinder head

F - Rocker arm support

1 7 - 7/16 x 1-7/8 plain stud

G - 3/8 x 2- 1/2 cap screw

1 8 - 5/16 x 1- 1/2 plain stud

H - 3/8- in. lock washer

L - 9/16-in. plain cylider head nut

J - Thrust spring

M - 9/16 x 1/8 thk cylinder head nut spacer

K - Cylinder head assembly

N - Front engine lifting bracket

1 - Valve spring retainer lock

P - 7/16-in. ljock washer

2 - Valve spring retainer

Q - 7/16 x 7/8 cap screw

3 - Intake and exhaust valve inner spring

R - Cylinder head gasket

4 - Intake and exhaust valve outer spring

S - Valve tappet

5 - Valve rotator

T - Valve rocker arm push rod

6 - 5/16 x 3 plain stud

U - 9/16 x 3/8 thk cylinder head nut flat washer

7 - Coolant transfer tube

V - Locating pin

8 - Core hole plug

FIGURE 385. CYLINDER HEAD ASSEMBLY AND RELATED PARTS - EXPLODED

VIEW - CONTINUED.

the seat. Rotate the valve one- half turn

and check valve contact area. Identify

Note. The key letters shown below in paren-

valve seats that do not show perfect

these refer to figure 385 except where other-

contact for future repair. Replace valve

wise indicated.

seats that are damaged beyond repair

or when they are cracked or loose (par.

a. Cleaning. Clean front cylinder head as-

20 a (2)).

sembly (K), valve springs (K-3 and K-4), intake

(3) Valves. Check intake valve (K-14) and

valves (K- 14), exhaust valves (K- 13), and valve

exhaust valves (K-13) for evidence of

rotators (K- 5) as directed in paragraph 152 c.

pitting, imperfect seating, or warpage

Remove heavy carbon deposits with a scraper

on valve head. Heavy discoloration,

or a wire brush. Do not nick or scratch the

burning, erosion, or a heavy carbon de-

gasket and valve seat surfaces. Remove carbon

posit on valve face indicates a warped

from injector nozzle and holder seats.

valve. A light frosted appearance or

minor discoloration on valve face does

b. Inspection.

not indicate a warped or unserviceable

valve. Inspect valve stems and locking

(1) Valve guides. Inspect valve guides (K- 9)

grooves in stems for pitting, scoring,

for cracks, galling, erosion, and scuf-

cracks, or damaged tips. Check valves

fing. Check guides for secure fit in cyl-

against limits specified in repair and

inder head. Check valve guides against

rebuild standards (par. 294). Replace

limits specified in repair and rebuild

valves that are cracked, warped, or

standards (par. 294).

otherwise unserviceable.

(4) Valve springs. Inspect inner spring

(2) Valve seats. Check intake valve seats

K- 3 and outer spring (K- 4) for wear,

(K-15) and exhaust valve seats (K-12)

cracks, set, or other evidence of failure.

for secure fit and for burned or pitted

Check springs against limits specified

condition. Check valve contact on seat

in repair and rebuild standards (par.

by coating the face with Prussian blue

and placing a new valve in position on

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |