|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

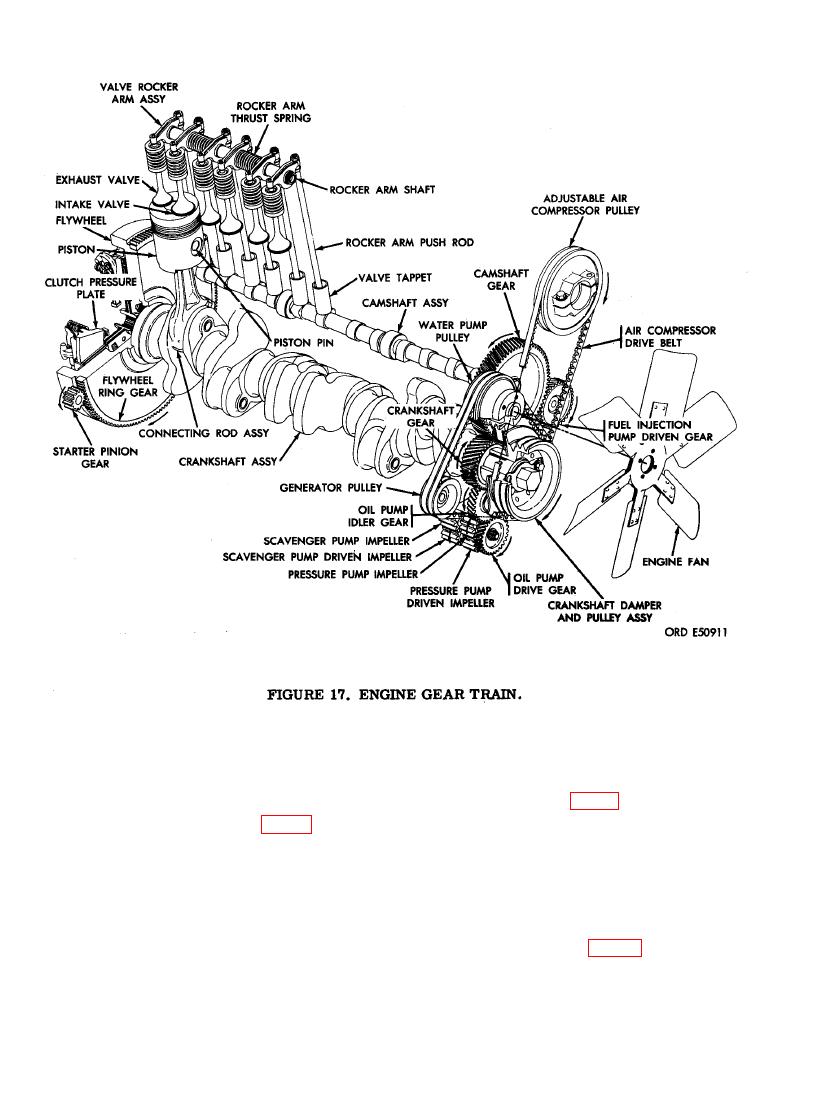

cheek and crank pin to provide a direct passage

which are cast integrally with the crankcase.

for pressurized oil to the connecting rod and

The seven main bearing caps are an integral

crankshaft main bearings. The crankshaft is

part of the cylinder and crankcase. The in-

dynamically balanced.

tegrally cast water jacket provides a uniform

transfer of heat to the engine coolant.

The seven main bearings are split, preci-

sion type and are steel backed with copper- lead

alloy bearing surfaces. The upper half of each

The crankshaft assembly is a one-piece unit

main bearing has an oil passage. The center

of forged and hardened steel. A flange is pro-

main bearing is double flanged with bearing

vided for mounting the flywheel. The other end

material to control crankshaft thrust and end

has a machined hub with a key slot to mount

play.

the crankshaft gear and crankshaft torsional

vibration damper and pulley assembly. All

crankpin journals are hollow to reduce weight.

Holes are drilled diagonally through each main

The six connecting rods are tapered, I-beam

bearing journal and extended through the crank

section, steel forgings. The connecting rod

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |