|

|||

|

|

|||

|

Page Title:

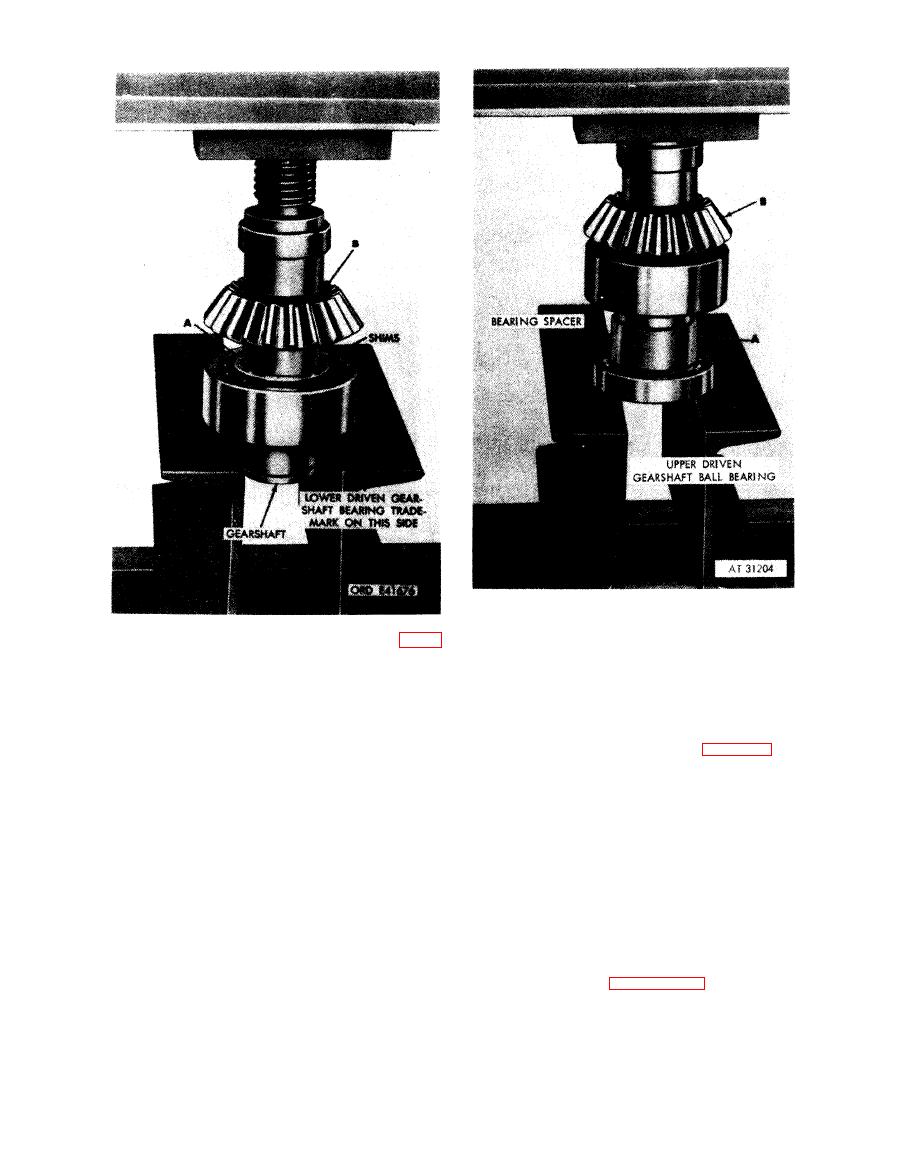

Figure 6-151. Pressing fart driven gearshaft into lower drive gearshaft ball bearing. |

|

||

| ||||||||||

|

|

1. Position bearing spacer (A) on fan driven gearshaft

and start upper driven gearshaft ball bearing on

1. Position shim (A) of predetermined thickness (fig. 6-

gearshaft

150) on inner race of lower driven gearshaft ball

2. Press gearshaft (B) into ball bearing.

bearing.

2. Press fan driven gearshaft (B) into ball bearing.

into upper driven gearshaft ball bearing.

into lower drive gearshaft ball bearing.

(b) D e t e r m i n e b a c k l a s h f o r f a n d r i v e b e v e l

e n d of inner bearing race (side opposite bearing

t r a d e mark) of front bevel gearshaft ball bearing.

Measure total thickness of bearing face and

shim. from shim on inner race to face of outer

race, with end play removed. Thickness should

be from 0.7891-inch minimum to 0.791 1-inch

maximum. When total thickness is more than

0.791 1-inch, strip 0.002-inch thick laminations

f r o m the shim pack until the correct thickness is

obtained. When total thickness is less than

0.7891-inch, add 0.002-inch thick shims

( s t r i p p e d from a new shim pack FSN 2930-678-

3 2 7 1 ) as necessary. Figure 6-150 illustrates shim

location and measuring points.

6-131

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |