|

|||

|

|

|||

|

Page Title:

Section XV. STEER COOLANT CHECK VALVE RETAINER ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

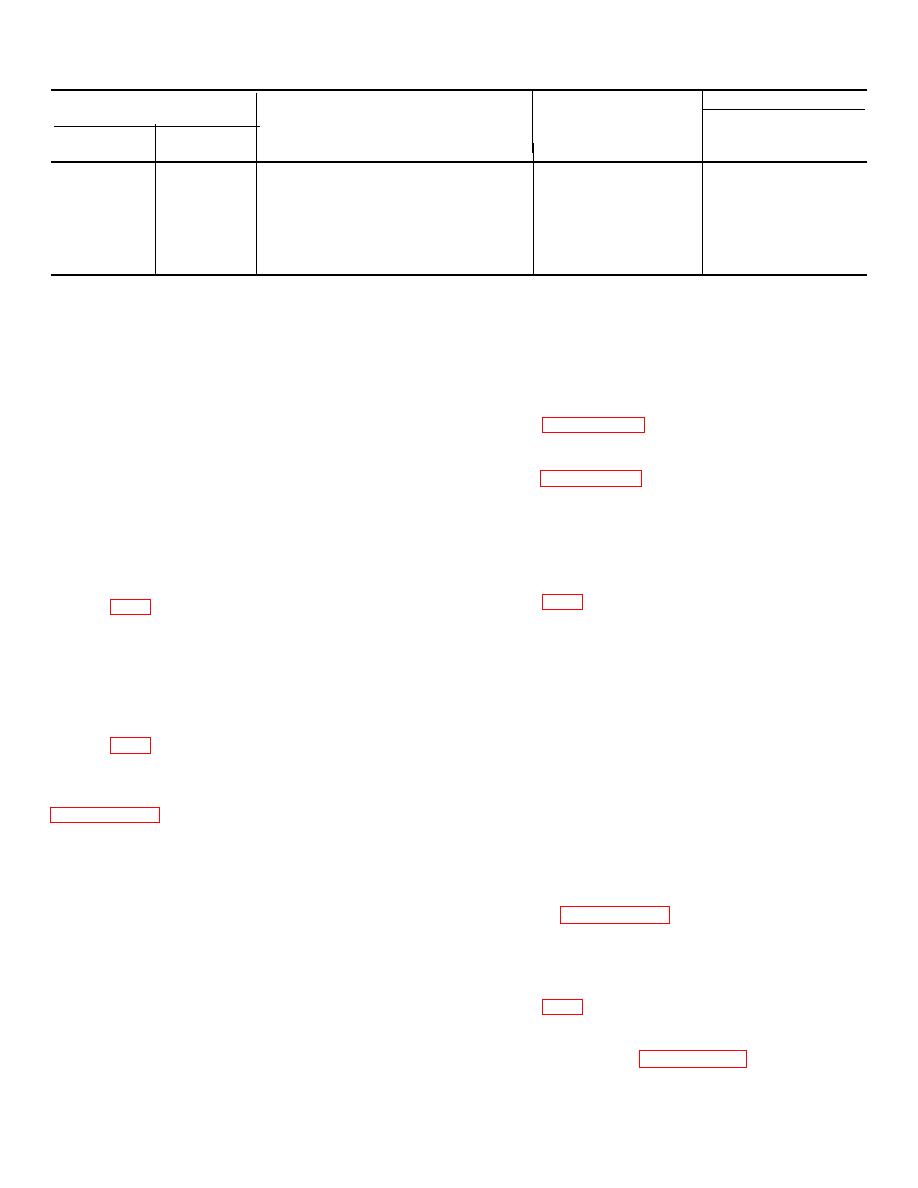

Table 7-12. Repair Standards (Bevel Drive Gear)--Continued

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

5

36a

Inside diameter of bearing inner race ...

4.2500 to 4.2510

*

5

38a

Outside diameter at bearing surface of .

4.2515 to 4.2525

4.2512

support

5

36a,

Fit of bearing inner race on support .....

0.0005T to 0.0025T

38a

*Replace when worn beyond new dimensions.

Section XV. STEER COOLANT CHECK VALVE

RETAINER ASSEMBLY-REPAIR

disk (30) from which the valve was removed.

NOTE

Right and left assemblies use

7-88. Cleaning

identical parts and require identical

Refer to paragraph 5-2 for cleaning recommendations.

repair procedures; however, the

assembly relation of parts differs for

7-89. Inspection and Repair

left and right. They must be kept

Refer to paragraph 5-3 for general inspection and repair

separate so that each will be

recommendations.

assembled

properly

in

the

transmission. Only the right side

7-90. Repair Standards

parts are referenced in the following

These components do not involve repair standards.

procedures.

7-91.

Assembly

7-86.

Description

The steer coolant check valve (53) is a two-diameter,

a. If any of the 11 guide pins (49) were

step-type, spool-shape valve. Its larger diameter end

removed from retainer (50) for replacement, install new

enters a bore in steer coolant check valve retainer

pins. Press each pin until it projects 1.to 1.80 inch above

assembly (48). The smaller diameter end passes

the flat side of the retainer.

through a hole in reverse-range reaction clutch disk

b. If alinement pin (51) was removed from

(30), where it is retained by a spring-type pin (52).

retainer (50) for replacement, install a new pin into the

7-87- Disassembly

same hole from the flat side of the retainer. Press the

pin in unit it projects 1.76 to 1.80 inch above the flat side

of the retainer.

a. Remove Teflon sealring (56) and expander

c. If valve (53) was removed from reaction

(55) from retainer assembly (48) as outlined in

disk (30) for replacement, install a new valve into the

same hole, from the same side of the plate as removed

b. Do not remove alinement pin (51) or guide

(marked at disassembly). Install retaining pin (52)

pins (49) from retainer (50) except for replacement. If

through valve (53), letting it protrude equal lengths at

alinement pin (51) is removed, mark the hole from

each side of the valve stem.

which it is removed for proper replacement.

d. Install expander (55) and sealring (56), as

c. Remove steer coolant check valve (53)

outlined in paragraph 7-55, preceding.

only if it needs replacement by pulling out pin (52). To

insure proper assembly, mark the hole and the side of

Section XVI. REVERSE-RANGE PLANETARY CARRIER ASSEMBLY-REPAIR

NOTE

7-92. Description

The right and left carrier assemblies

Reverse-range planetary carrier assembly (36) is 6

are identical, therefore, the right

pinion type carrier assembly with rollers (39.5) for each

assembly only is described in the

pinion (39.4). Refer to paragraph 2-11.

following procedures.

7-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |