|

|||

|

|

|||

|

Page Title:

Section VIII. LOW- AND INTERMEDIATE-RANGE CLUTCH SPACER ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

Section VIII. LOW- AND INTERMEDIATE-RANGE CLUTCH

SPACER ASSEMBLY-REPAIR

7-46. Inspection and Repair

Refer to paragraph 5-3 for inspection and repair

Low- and intermediate-range clutch spacer assembly

recommendations.

(36) separates the low-range (41 and 42) and the

intermediate-range (27, 28, 33, and 34) clutch disks.

7-47. Repair Standards

Eight pins (38) are pressed through spacer (37) to

anchor the external-tanged clutch disks (27, 33 and 41).

repair standards.

Refer to paragraph 2-7.

Do not remove pins (38) from spacer (37) except for

a. If pins (38) were removed from spacer (37),

replacement.

install new ones.

7-45. Cleaning

b. Install new pins (38) into shallow side of

Refer to paragraph 5-2 for cleaning recommendations.

spacer (37). Press each pin in until it projects 0.900

inch above the highest surface of the spacer.

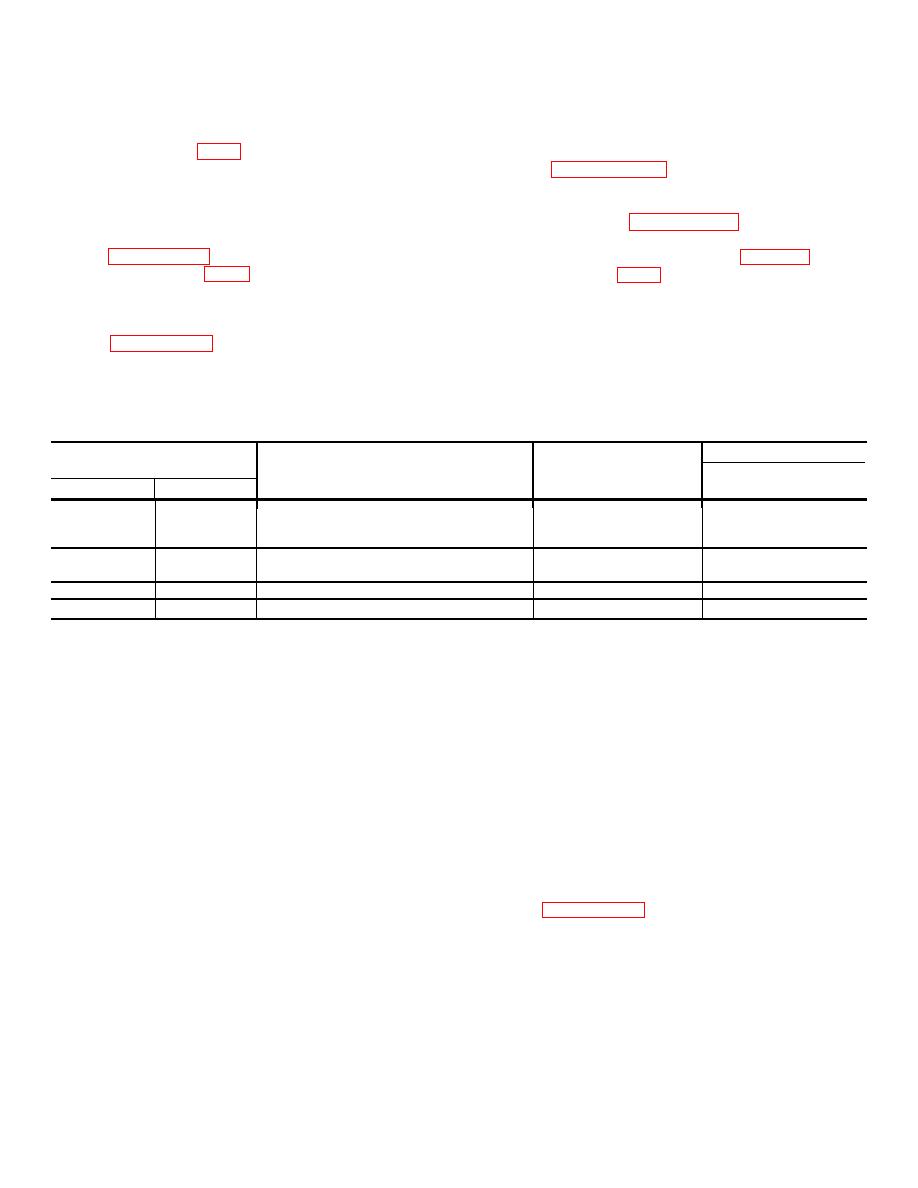

Table 7-7. Repair Standards (Low-, Intermediate-range Clutch Spacer)

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

4

27a,

Thickness of disk..................................

0.1166 to 0.1226

*

33a

4

28a.

Thickness of disk..................................

0.1580 to 0.1630

0.1480

34a

4

41a

Thickness of disk..................................

0.1166 to 0.1226

*

4

42a

Thickness of disk................................. .

0.1580 to 0.1630

0.1480

*Replace when worn beyond new dimensions.

Section IX. TEFLON SEALRINGS AND EXPANDERS-REPAIR

7-51.

Removal

7-49. Description

Teflon sealrings have better wear characteristics, but

a. Insert a thin bladed tool (such as shim

are less elastic than rubber-type rings. They require an

stock) into the sealring groove, and work one edge of

expander in most cases where the endless sealring is

the sealring out where it can be grasped by the fingers.

used. The expander is a thin wavy strip of metal with

WARNING

open ends and goes into the bottom of the groove

Do not dispose of Teflon sealrings by

between the sealring and the piston.

burning. Toxic gases are produced.

7-50. Instructions Apply to All Clutches

b. Remove the sealring expander. Clean the

a. These instructions apply to the installation

groove thoroughly, and make sure there are no burs or

of Teflon sealrings and their expanders into all pistons

rough spots in the groove sides or bottom.

or other components, regardless of the clutch applied by

7-52. Cleaning

the piston using these rings.

Refer to paragraph 5-2 for cleaning recommendations.

b. All overhaul sections in this chapter which

involve sealrings and expanders are referenced to this

section for removal and installation.

7-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |