|

|||

|

|

|||

|

Page Title:

Table 7-1. Mechanical Connections |

|

||

| ||||||||||

|

|

TM 750-245-4

7-8. Thoroughness of Inspections

(3) Periodic inspection of tools for proper

Thoroughness of inspections will prevent unsatisfactory

maintenance.

equipment from being released from the maintenance

(4) Replacement of tools when worn beyond

shop. The inspector must initiate the inspection at a

established limits.

common point for soldering operations. The following is

c. Control of Materials Used During Repair

offered to attain a standard level of workmanship:

Procedures.

a. Review the job order (DA Form 2407) to

(1) Only qualified products are to be used.

determine which components were repaired or replaced.

(2) Disposal of excess or unqualified

Connections should meet the requirements of this

materials.

chapter.

7-7. Workmanship Standards

examined to determine adequacy.

Workmanship standards for soldering operations

encompass two areas:

7-9. Mechanical Connections

a. The repairman should be trained in soldering

techniques.

mechanical connections prior to soldering.

b. Workmanship for the inspector is based upon

the inspector's knowledge of the equipment he is

inspecting and knowledge of inspection requirements.

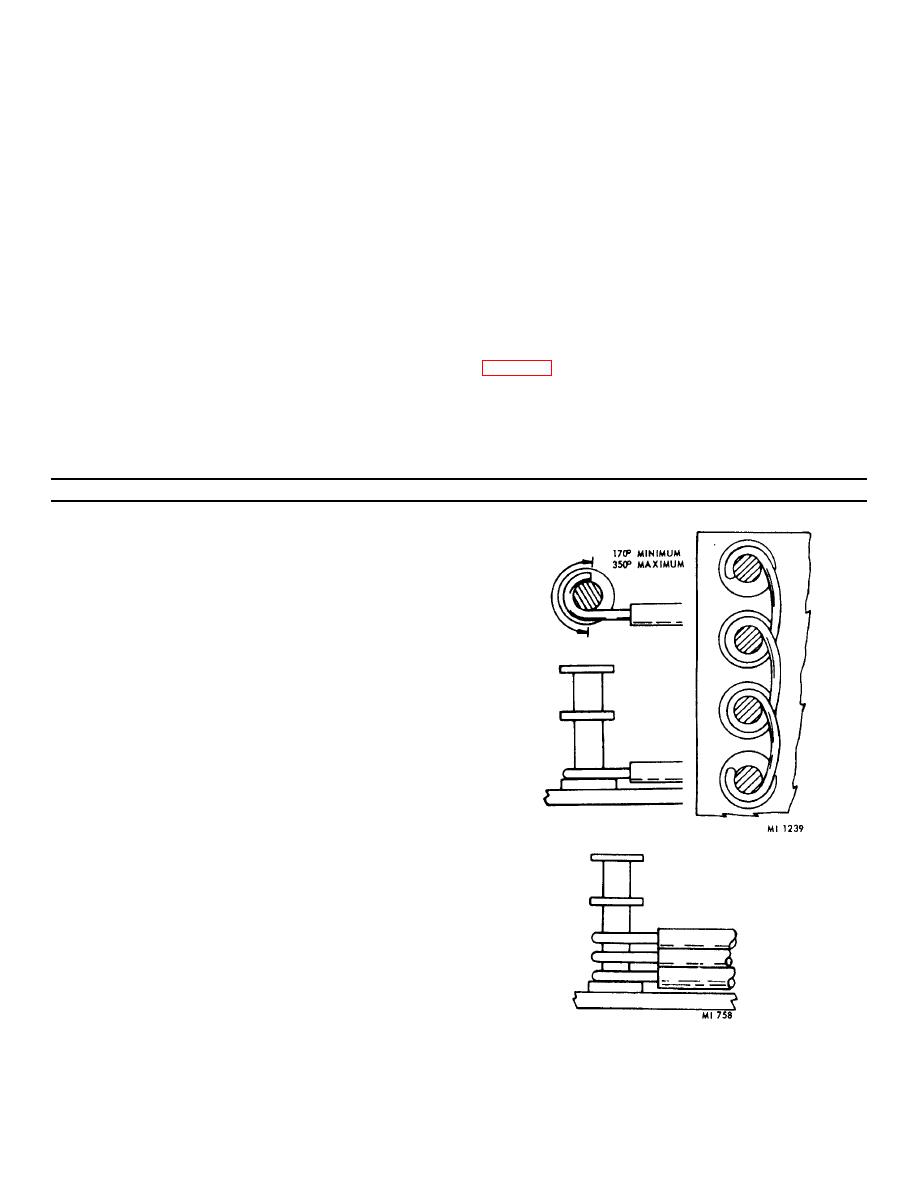

Table 7-1. Mechanical Connections

Connector type

Illustration

Turret terminal wrap

Turret terminal multi-connection

7-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |