|

|||

|

|

|||

|

Page Title:

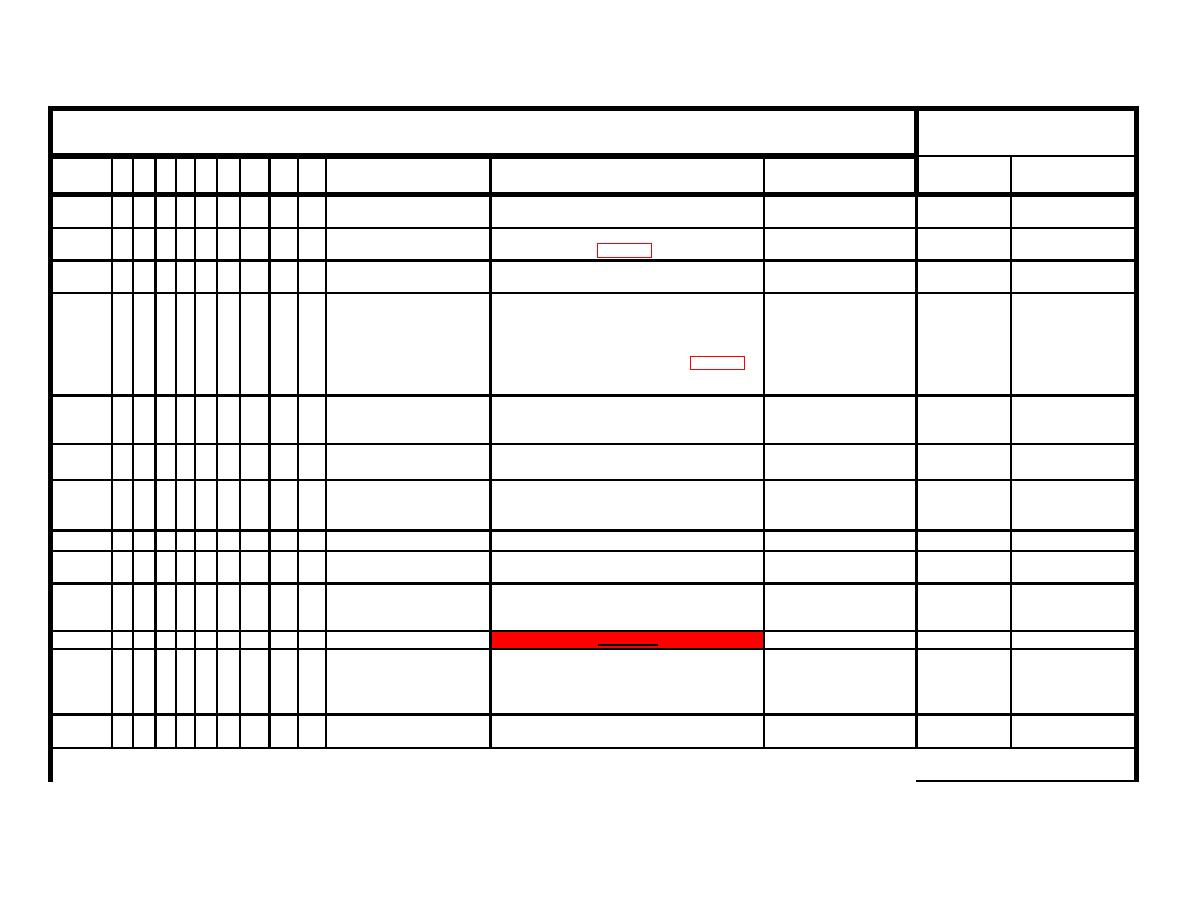

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

X

X

X

Inspect winch for hydraulic and oil leaks. Refer to Repair leaks as necessary. Class III leaks.

75

Stern Ramp Jigger Winch

TM 55-1915-212-24&P.

X

Check oil level in the gear case. Refer to Chapter Add oil as necessary.

2, Section III, Para. 2-5.18.2.

X

Inspect cables for serviceability.

Replace cable as

necessary.

Deck machinery

Inspect power units and moving parts of capstansAdd oil as necessary.

X

X

X

76

Deck Machinery

non-operational

Repair deck machinery as

for serviceability. Ensure deck machinery is

necessary.

securely mounted and that connections are

properly aligned. Check oil level in gear cases.

Refer to Chapter 2, Section III, Para. 2-5.17.1

X

Check that pressure/vacuum gauge shows a

Troubleshoot, repair or

77

Groen TOB/6 Kettle

vacuum reading of 20 to 30 inches when the kettle replace as required.

is cold.

X

Jacket Water Level

Check that water level is between the marks on

Add water as needed.

the gauge glass.

X

Electrical Wiring

Check that electrical wiring is securely connected. Repair/replace frayed or

Frayed or

Check for frayed or damaged wiring.

damaged wiring.

damaged wiring.

X

Support Housing

Check that interior of housing is clean.

Clean as necessary.

X

Safety Valve

Check that safety valve works freely.

Repair/replace safety valve. Safety valve

inoperable.

Clean as necessary.

Inspect condenser coil to make certain that air

X

78

Marine Reach-in

Remove debris.

flow is not hampered and that it is clear of dust

Freezer/Refrigerator

and debris.

WARNING

Prior to any cleaning of the system involving

moving parts, the system should be deactivated

by disconnecting the power supply cord or

personnel injury may result.

X

Drain Line

inspect and check drain line to ensure it is not

Unplug drain line.

plugged up.

LSV PMCS

Change 12

2-286

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |