|

|||

|

|

|||

|

Page Title:

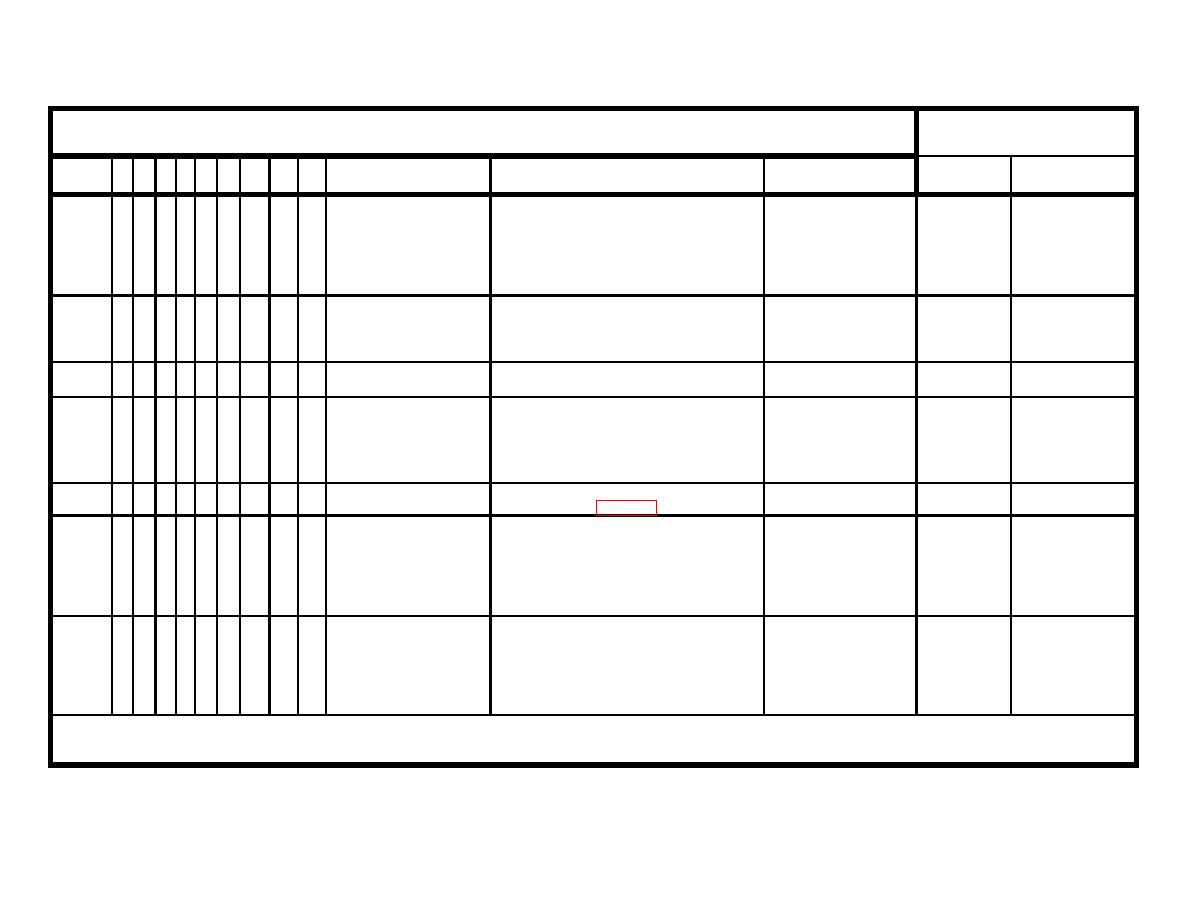

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

X

X

Sealing Gasket

Inspect sealing gasket for damage from contact Refer to supervisor, higher

With ramp closed,

with cargo, or for accumulations of foreign matter level of maintenance for

watertight fit is not

such as grit, oil, paint, etc. In addition, the gasket repair/replacement.

achieved.

should be checked for cracks or permanent set of

more than 50 percent of design compression.

X

X

X

Inspect ramp winch for hydraulic and oil leaks.

Repair leaks as necessary. Class III leaks.

73

Bow Ramp Winch

Refer to TM 55-1915-211-24&P.

LO/LO

Operations only.

X

Inspect clutches, drag brakes and automatic

Repair as necessary.

brake lining serviceability.

X

X

Inspect anchor chain that is VISIBLE for unusual Refer to unit maintenance

deterioration or visible defects. Complete runout offor repair.

chain is not required. Inspect only that chain

section VISIBLE is in the as-stored condition.

X

X

Check oil level in the gear case. Refer to Chapter Add oil as necessary.

2, Section III, Para. 2-5.18.2.

X

X

X

Inspect stern ramp and related components

Refer to supervisor and unit Evidence exists

74

Stern Ramp

including wire rope, hinges, sheave assemblies, maintenance.

that proper and

hydraulic jigger winch, hydraulic controls and

unsafe operation

ratchet dogs for proper adjustment, damage, or

is not possible.

excessive wear.

Inspect sealing gasket for damage from contact Refer to supervisor, higher

With ramp closed,

X

X

Sealing Gasket

watertight fit is not

with cargo, or for accumulation of foreign matter level of maintenance for

achieved.

such as grit, oil, paint, etc. In addition, the gasket repair/replacement.

should be checked for cracks or permanent set of

more than 50 percent of design compression.

LSV PMCS

Change 12

2-285

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |