|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-4940-544-14&P

Lubrication

Proper lubrication is essential to trouble-free op-

eration and Iong life of Portable Hose Assembly

Machine.

1. Grease main shaft bearings every 6 months or

oftener if subject to hard use.

Note: Grease Fittings are provided on side of

base, one at each end of shaft. Use a

good grade of cup grease.

2. Disassemble, clean, and grease Chuck Jaws

and Inserts yearly.

3. Lubricate Vise Assembly as required for smooth

operation.

Motor Brush Replacement

Check Motor Brush Assembly every 6 months and

replace when worn to less than inch. If Com-

mutator is worn, turn O.D. of Commutator and

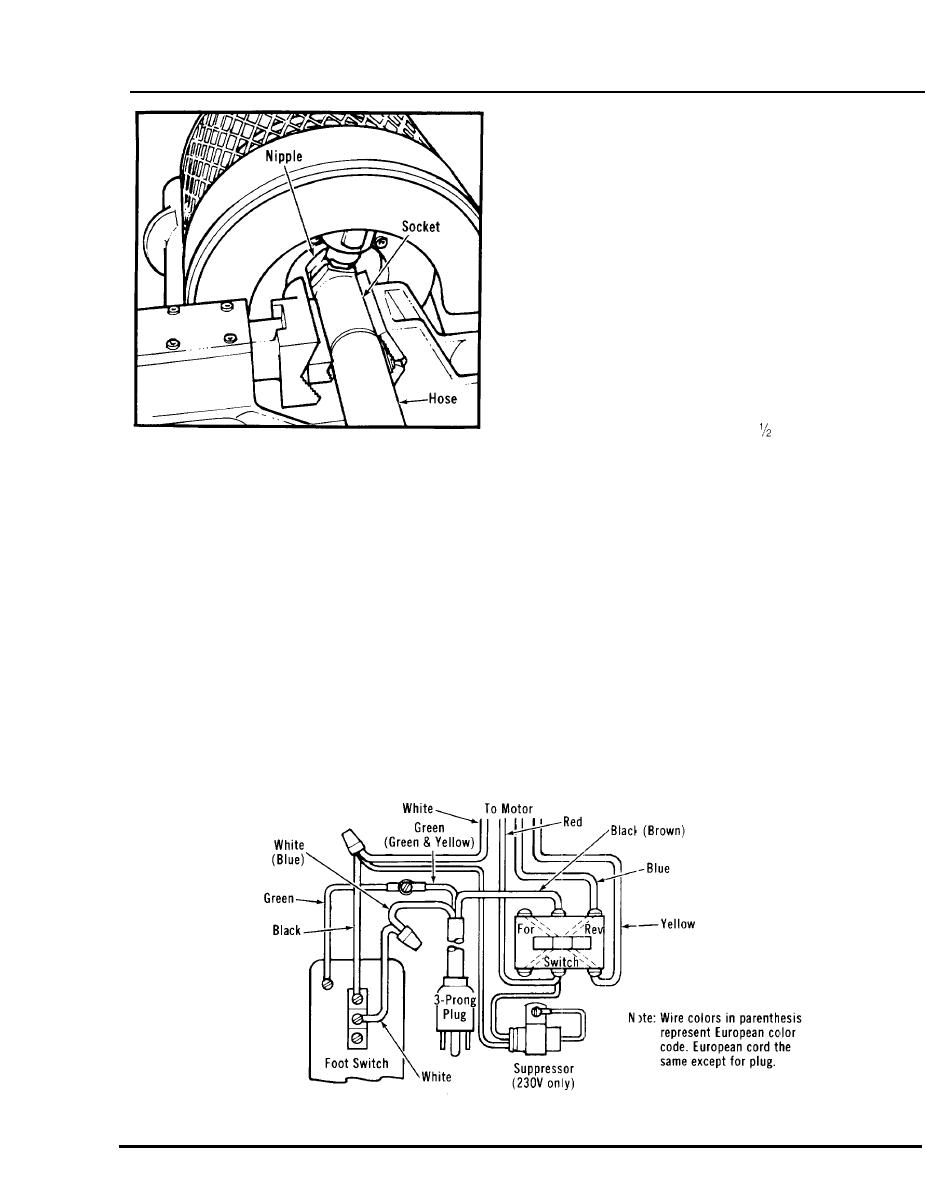

Figure 8. Assembled Hose, Socket, and Nipple.

undercut mica before replacing Brush Assembly.

Motor Replacement

1. Remove two Screws holding Switch Box.

2. Remove two Screws holding Motor.

Maintenance Instructions

3. Loosen Lock Screw in body at neck of Motor.

4. Lift Switch Box and Motor out.

5. Loosen Switch Box Connector holding motor

wires.

Warning: Always disconnect machine from power

source before servicing.

6. Remove red, yellow and blue motor wires on

switch.

General Care

7. Disconnect Wire Nut.

Periodically check machine for loose bolts and

screws. Maintain Power Cord and Foot Switch

Note: Motor is now free from Power Drive.

Cord in top condition. Check frequently.

Figure 9. Portable Hose Assembly Machine Wiring Diagram.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |