|

|||

|

|

|||

|

Page Title:

ASME-A Pressure Feed, MATERIAL TANKS |

|

||

| ||||||||||

|

|

ASME-A Pressure Feed

OPERATING INSTRUCTIONS and

MATERIAL TANKS

REPLACEMENT PARTS

1. CLEAN OUT TANK and blow out all hose before

using. Always use hose of ample size.

2. MATERIAL TO BE USED must be thoroughly

mixed and strained through a fine mesh strainer

or cheesecloth before or while pouring into tank.

Follow material manufacturers instructions

regarding proper type and amount of thinner to

be used.

3. When using the Airmotor Agitator do not fill tank

over the required amount, 3/4 Full .This is to

prevent paint from entering the Agitator

4. PLACE COVER ON TANK. Turn each clamp

down until it touches the cover. Proceed around

the cover, turning each clamp one full turn until

all are tight. This method insures longer gasket

life and uniform sealing.

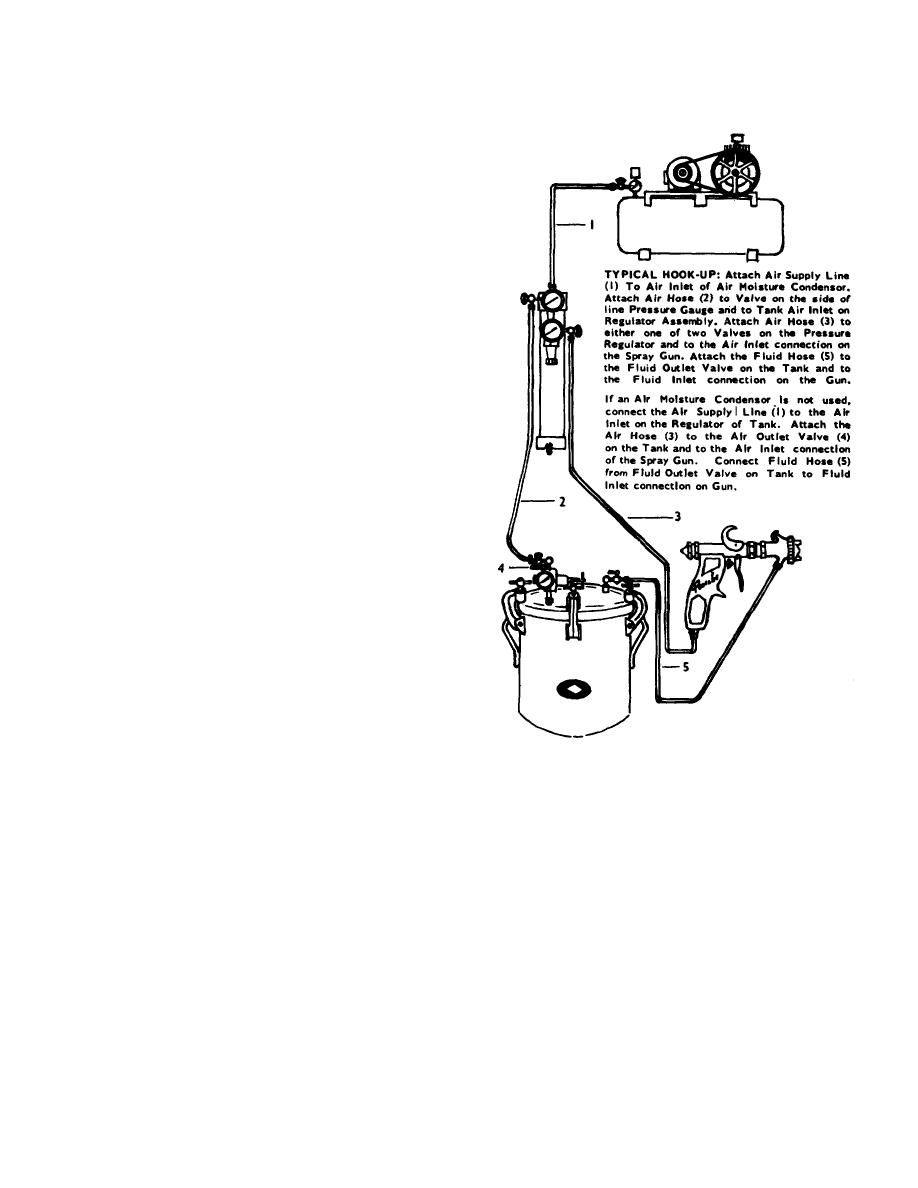

5. FOLLOW HOOK-UP INSTRUCTIONS AT

RIGHT.

6. OPEN AIR LINE VALVE on Air Regulator and

Moisture Condensor Unit to allow air pressure to

enter tank.

7. ADJUST AIR PRESSURE for material by

turning the adjusting handle on the tank

regulator

until

the

gauge

indicates

approximately 5 lbs. When it is necessary to

decrease pressure in the tank, the excess

pressure must first be released by opening the

release valve.

a. CAUTION: Release valve should be opened

before removing filler plug or cover.

8. PROPER FLUID PRESSURE will vary from 2

lbs. upward, depending upon the consistency of

the material and the height to which fluid must

be raised.

CARE AND CLEANING

9. FLUID PRESSURE should be adjusted to give a

1. Tank should be kept in upright position to keep

uniform flow. Use lowest pressure that gives

liquids and materials away from inside part of

satisfactory results.

Cover, Air Passales Must Stay Clean.

10. TO CLEAN HOOK-UP, Remove all pressure

2. PU 566 Splash Cap on Regulator Air Outlet

from the tank by opening the release valve.

inside Tank Cover should be inspected

Then force material back into the tank by

periodically to make sure Air Ports are open to

loosening the air cap of the gun, holding a wad

admit Airpressure entering Tank.

of cloth over the air cap and pulling the trigger.

3. U8II Air Inlet Strainer in Tank should be

Air thus diverted into the fluid lines forces

Cleaned periodically to remove any skins or

material back into the container.

Remove

heavy particles which might clog the openings.

material from the tank and replace with clean

The same applies to the Spray Gun and Tank

solvent. Apply pressure again to the tank and

Regulator.

spray solvent through the gun to flush out the

MATERIAL:

fluid passages and hose. Wipe off equipment

Fluid material should be mixed to consistency

with a solvent soaked rag.

recommended by manufacturer and should always be

11. NEVER ALLOW SAFETY VALVE TO BECOME

strained through a lint free cloth or metal screen before

COVERED WITH PAINT.

using.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |