|

|||

|

|

|||

|

Page Title:

Inspect sleeve bearing for rough spots |

|

||

| ||||||||||

|

|

TM 9- 2920- 232- 34&P / TO 38X14- 2- 32

-

-

-

- -

DISASSEMBLY OF THE STARTER ASSEMBLY - CONTINUED

-

0008 00

k.

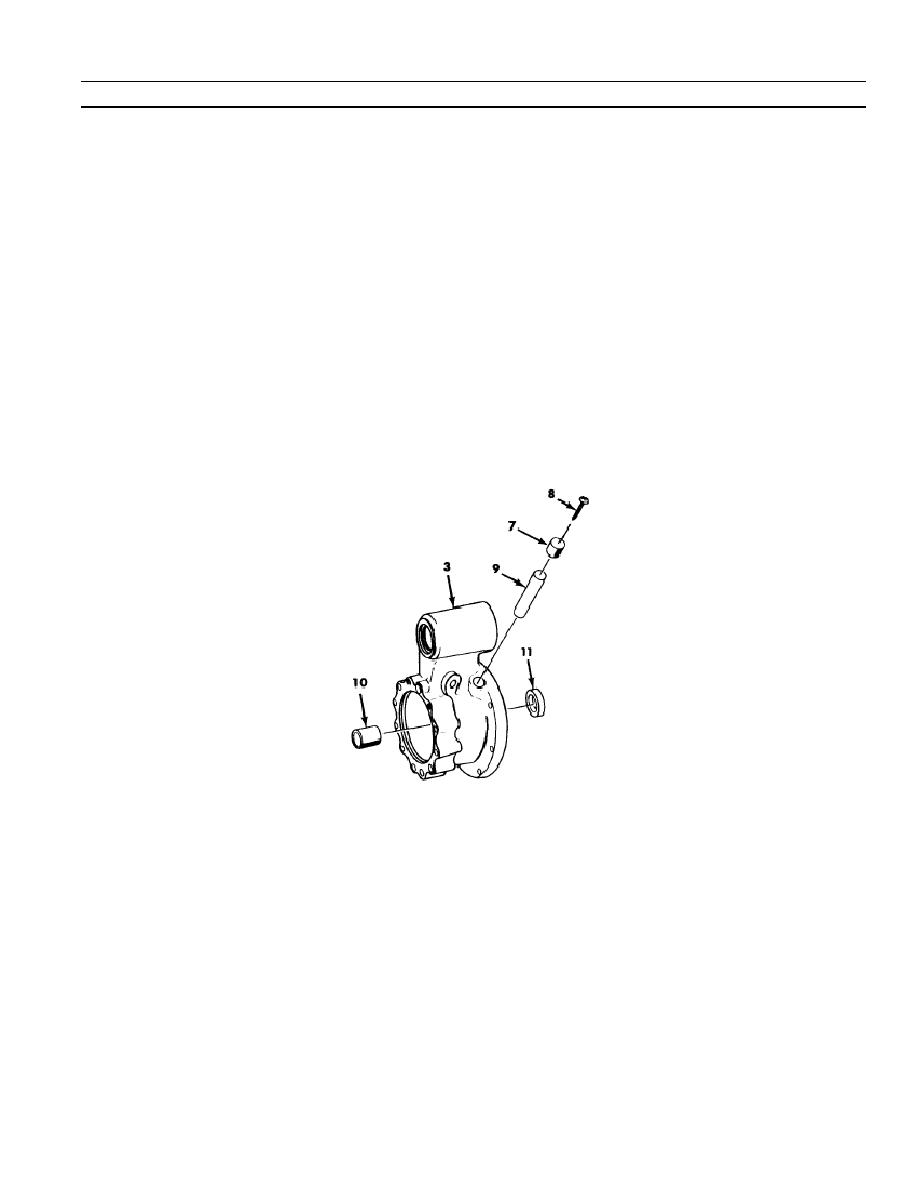

Drill a 5/32 inch hole near the center of exposed surface of oil reservoir cap (7) and thread a thread forming

tapping screw (8) into this hole to use as a puller. Remove cap and wick (9) and discard.

l.

Inspect sleeve bearing for rough spots, score marks, scratches, and nicks. Replace if defective.

NOTE

Do not remove sleeve bearing to check outside diameter and housing bore diameter unless

bearing is loose in housing exceeding the 0.0040 to 0.0060 inch interference fit limits.

m. The wear limits for lever housing sleeve bearing inside diameter should not exceed 0.8335 to 0.8365 inch and

outside diameter should not exceed 0.962 to 0.963 inch. Use a suitable puller from the bearing puller set to

remove sleeve bearing (10) from lever housing (3). Discard bearing.

n. Using a suitable puller from bearing puller set, remove oil seal (11) from lever housing (3). Discard oil seal.

o. Inspect lever housing for cracks or warp age. Check for scratches, burs, and nicks on machined surfaces.

Replace if defective.

p. Check bearing, lever shaft, and oil seal bores in housing. Replace housing if lever shaft bore exceeds 0.9570

to 0.9580 inch, lever shaft bore exceeds 0.508 to 0.512 inch, and oil seal bore exceeds 1.3740 to 1.3760 inch.

q. Inspect threads in tapped holes in lever housing. Replace housing if threads are stripped.

0008 00- 15

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |