|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9- 2920- 224- 34&P

-

-

-

ASSEMBLY OF THE GENERATOR - CONTINUED

-

0010 00

Assembly

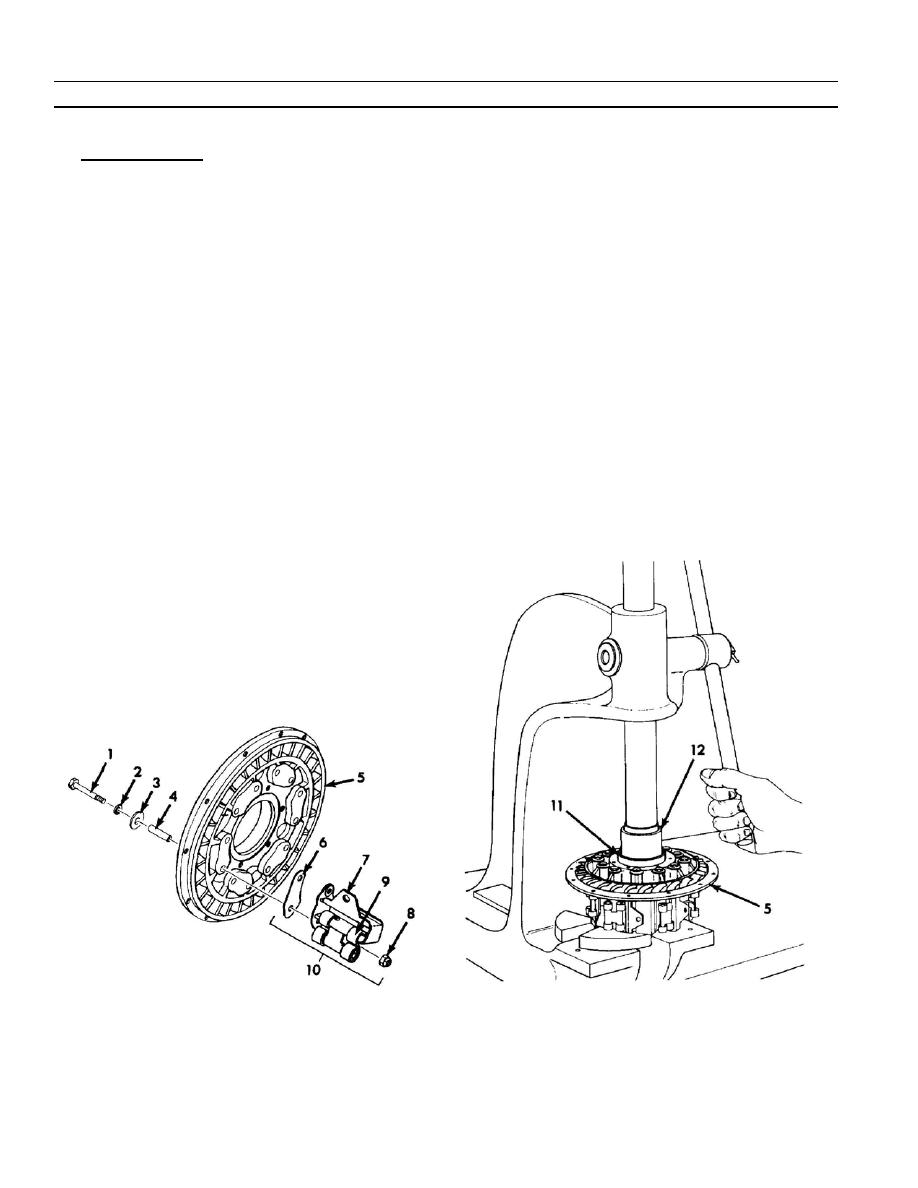

1. Electrical End Bell.

a. Install metal flat washer (2), insulating flat washer (3), and tube (4) on each of two machine bolts (1). Install

these bolts through one brush holder pad on generator support assembly (5).

b. Install one plate insulator (6) over ends of bolts (1), make sure contour of insulator (6) fits contour of brush

holder pad on support assembly (5).

c.

Position one holder (7) over ends of bolts (1) and against plate insulator (6) on support assembly (5). Install

and tighten two new self--locking nuts (8). Torque to 25--30 Ib--in (2.8 to 3.4 Nm).

d. Install each of remaining five electrical contact assemblies (10) by repeating steps a thru c. If torsion spiral

springs (9) were removed for inspection or replacement during disassembly, install all springs (9) on their

respective holders (7) in the position shown.

e. Apply a coating of insulating compound to the head of each bolt (1), make sure that compound covers both

flat washers (2) and (3). Apply compound around attaching flange of each holder (7) and mounting pad on

support assembly (5). Allow compound to dry thoroughly before installing bearing in support assembly.

f.

Apply a film of light grease to bore of bearing liner in support assembly (5) and press annular ball bearing (11)

into bore of support assembly (5) as shown. Use an arbor press and an arbor (12) slightly smaller in diameter

than outside diameter of outer bearing race, as it must make contact with outer bearing race only.

g. Check insulation of electrical end bell. Using a multimeter, check continuity on each brush holder terminal.

Multimeter should read 0 continuity between brush holder.

0010 00- 2

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |