|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM9-2815-224-34&P

Fan Clutch Maintenance Instructions

18-2. FAN CLUTCH REPAIR (CONT).

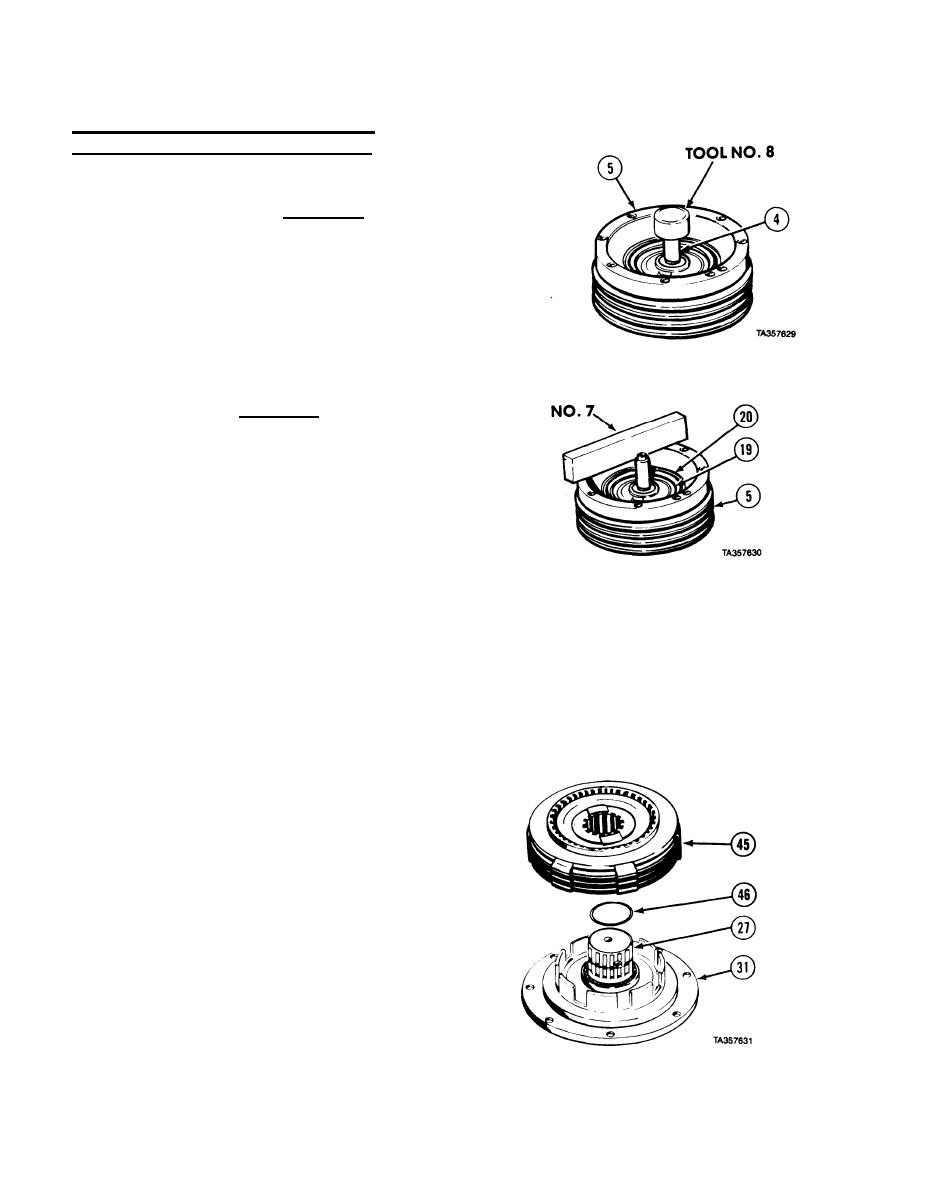

(64) Support fan pulley (5) with suitable blocking.

CAUTION

Apply only slight pressure on shaft when alining shaft straight

up and down, or parts on fan hub may be damaged or

improperly alined.

(65) Aline bracket and shaft assembly (4) straight up and down

using tool No. 8.

CAUTION

Do not place tool No. 7 over screw holes or

improper measurements may result and cause

damage to clutch parts.

(66) Place tool No. 7 on fan pulley (5).

(67) Measure and write down distance between top

side of tool No. 7 and thrust washer (19), Take

measurement next to retaining ring (20).

(68) Move tool No. 7 and repeat step (67) on opposite

side of fan pulley (5).

(69) Add measurement from step (67) to measurement from step (68) and write down answer.

(70) Subtract 2.00-in. (50.8 mm) from result in step (69) and write down answer. This is

measurement B.

(71) Subtract measurement B from measurement A, step (63), and write down answer.

(72) Subtract answer in step (71) from 0. 136-in. (3.45 mm). This answer is shim gap indicator.

(73) If shim gap indicator is 0.000 to 0.008 in. (0.00 to 0.20 mm), shim is not required. If gap is

0.009 to 0.028 in. (0.23 to 0.71 mm), use 0.010 in. (0,25 mm) shim. If gap is 0.029 to 0.048 in.

(0.74 to 1.22 mm), use 0.020 in. (0.51 mm) shim. If gap is 0.049 to 0.068 in. (1.25 to 1.73 mm),

use 0.030 in. (0.76 mm) shim. If gap is 0,069 to 0.088 in. (1.75 to 2.23 mm), use 0.040 in.

(1.02 mm) shim, and if gap is 0.089 to 0.108 in. (2.26 to 2.74 mm), use 0.050 in. (1.27 mm) shim.

NOTE

When removing clutch assembly, carefully lift out

assembly so all parts remain together for easy

installation.

(74) Remove clutch assembly (45) from bearing

retainer (31).

(75) Apply grease to shim (46).

(76) Install shim (46) on fan hub (27).

18-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |