|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Blower Maintenance Instructions (Cont)

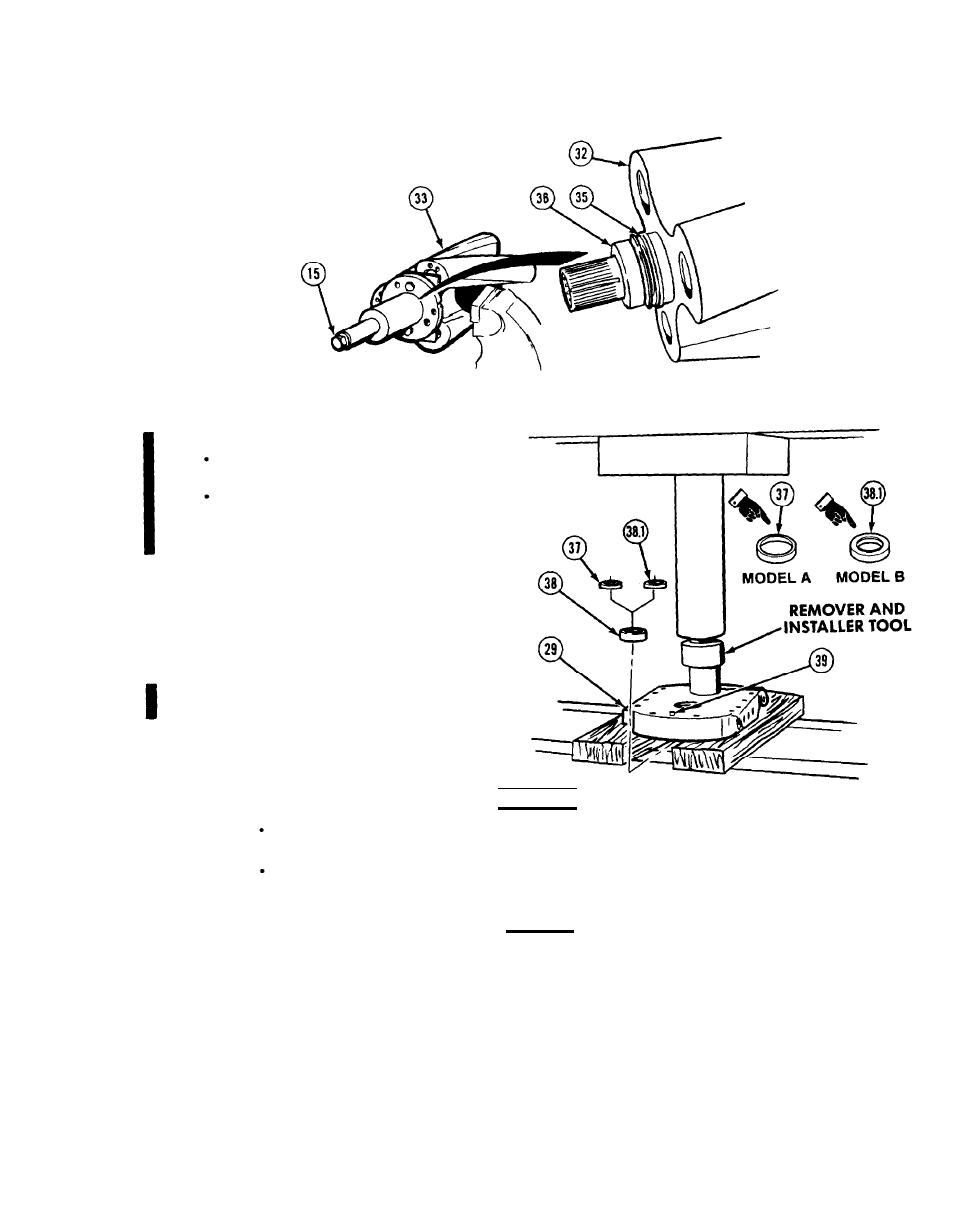

Install puller tool to adapter with two screws. Turn puller screw (15) to remove ring carrier (35)

(27)

and inner bearing race (36) from rotors (32 and 33).

NOTE

Repeat steps (29) through (31) for

front and rear end plates.

Seal ring collar on Model A only. Do

steps (28), (29), (30), and (31) for

Model A. Do steps (28), (29), (30.1),

and (31) for Model B.

(28) Position rear end plate (29) on wood

blocks.

(29) Place long end of remover and installer

tool through seal ring collar (37) into

ball bearing (38).

(30) Press out ball bearing (38) and seal ring

collar (37).

(30.1) Press out ball bearing (38) and double

lip seal (38.1).

(31) Inspect dowel pins (39) for breakage or

damage. Replace if broken or damaged.

b. Cleaning/Inspection.

WARNING

Adhesives and solvents burn easily and give off harmful vapors. To avoid injury, use

in a well ventilated area and keep away from flame.

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.).

CAUTION

Do not use compressed air on bearings. Allow bearings to air dry. Compressed air

may cause damage to bearings.

( 1 ) C l e a n metal parts in drycleaning solvent. Dry parts other than bearings with compressed air.

(4) Inspect oil holes. If clogged, clean with drycleaning solvent.

(5) Inspect all finished surfaces for burrs and scoring. Use crocus cloth to clean.

14-21

Change 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |