|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM9-2815-224-34&P

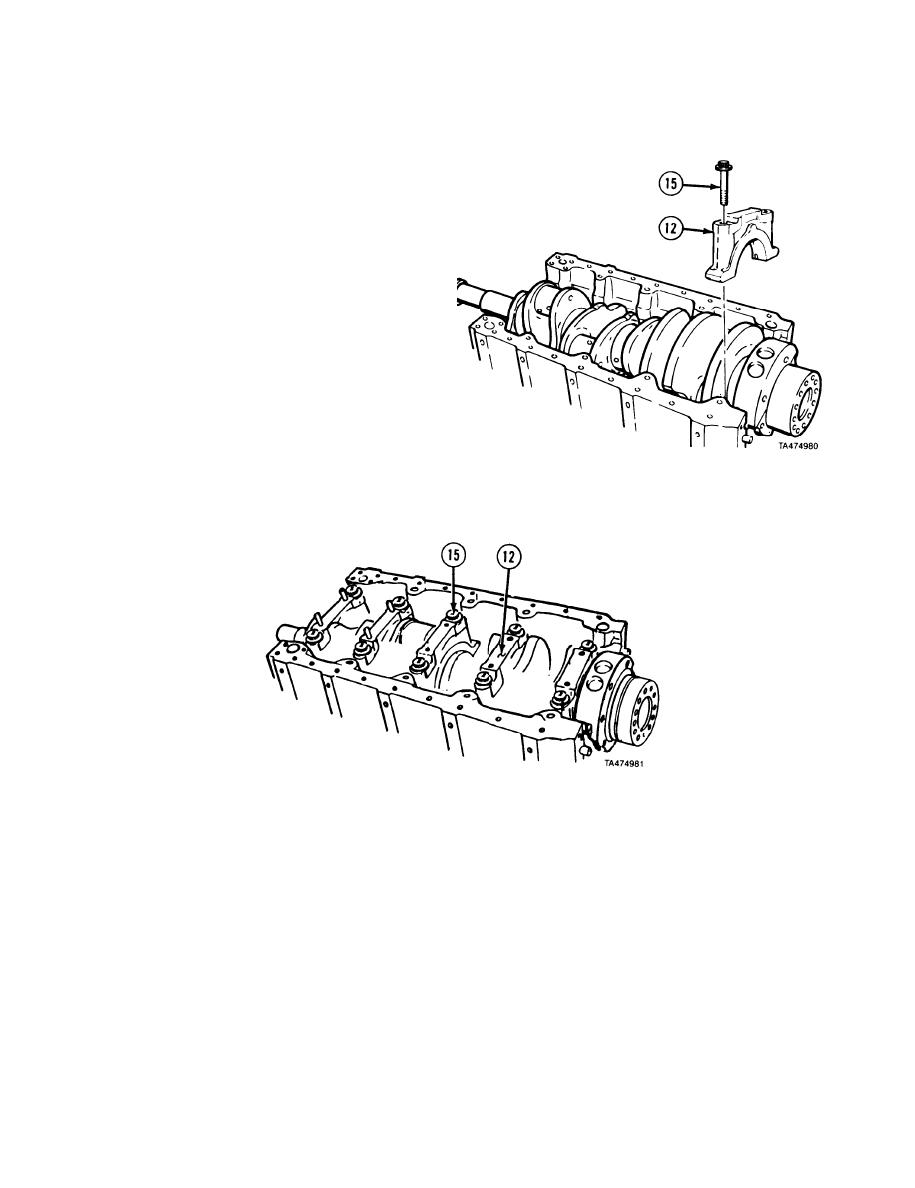

Crankshaft Maintenance Instructions (Cent)

(13) Install five bearing caps (12).

(14) Strike bearing caps (12) with

soft-face hammer.

CAUTION

When installing bearing cap screws on

engines built prior to Serial No. 8VF085 187

replace all ten flanged head screws

with new 12-point screws with

captured washers. If engine has new

type screws, individual screws may be

replaced. Mixing of old type and new

type screws may cause damage to

engine.

(15) Install ten screws (15).

(16)

Tighten ten screws (15) to 50 lb-ft (68 N-m).

(17)

Strike bearing caps (12) with soft-face hammer.

(18)

Tighten ten screws (15) to 110 lb-ft (149 N-m).

(19)

Tighten ten screws (15) to 230 to 240 lb-ft (312 to 325 N-m).

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |