|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-270-34

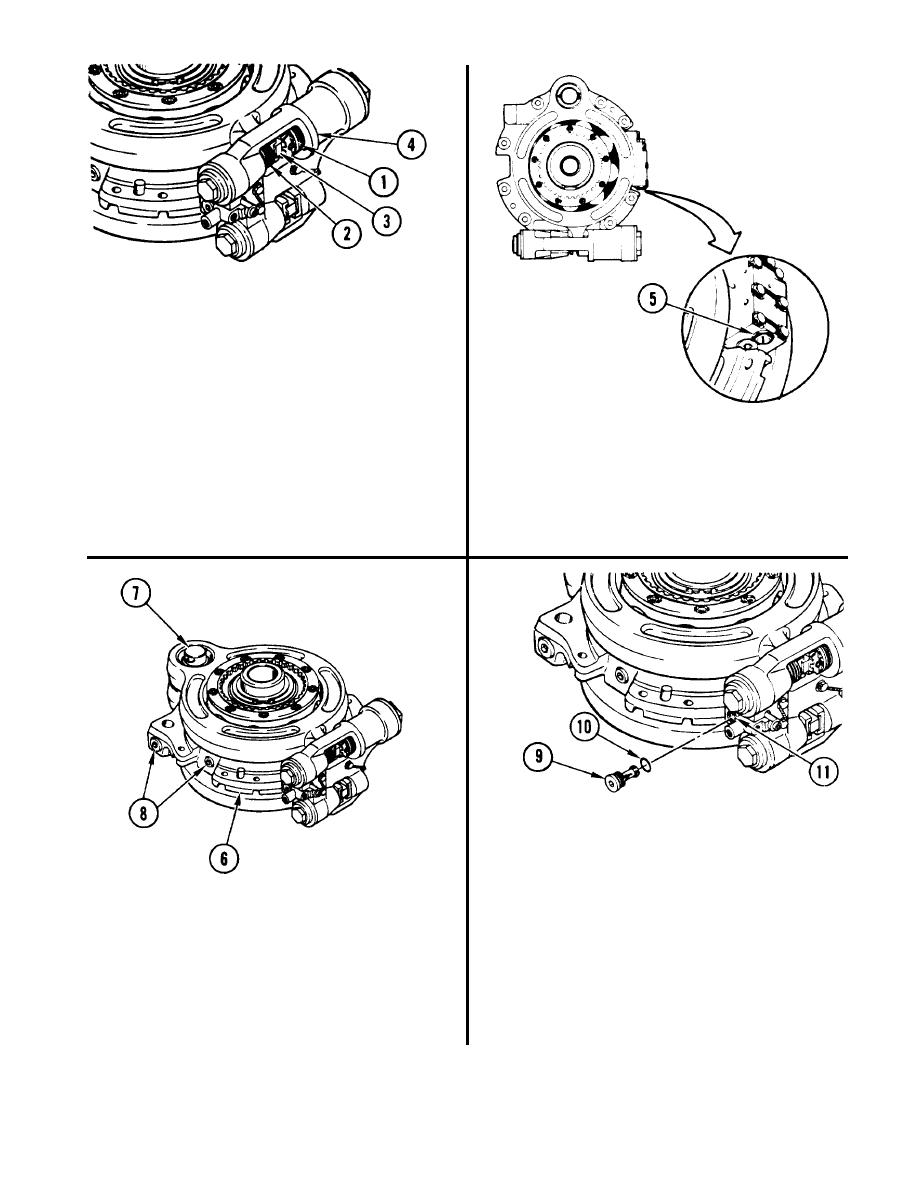

19. CHECK ACTUATOR PISTON

A S S E M B L Y (1) AND ACTUATOR

PISTON (2).

Move tang (3) back and forth by

a.

pressing piston (1) into housing (4)

with finger and releasing.

b.

If tang (3) moves freely and pistons (1)

and (2) move smoothly back and forth,

go to step 20.

20. INSPECT PLAIN NUT (5).

c.

If tang (3) does not return smoothly

a. If nut (5) is tight, go to step 21.

to center position with pistons (1)

If nut is loose or missing, go to

and (2) resting against tang, go to

step 37.

step 37.

22. REMOVE PRESSURE FLUID FILTER (9).

a. Using 3/8-inch drive ratchet handle and

5/16-inch socket wrench attachment,

remove filter (9).

21. INSPECT PINTLE ASSEMBLY (6).

b. Remove preformed packing (10)

a. If pintle assembly (6) and pin (7) are

23. INSPECT FILTER (9) AND

not damaged and plugs (8) are

FILTER CAVITY (11).

installed, go to step 22.

a. If metal chips are found, go to

b. If pintle assembly (6) or pin (7) is

step 24. If not, discard packing (10)

damaged or plugs (8) are missing, go to

and go to step 26.

step 37.

GO TO NEXT PAGE

4-393

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |