|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-238-34

REPAIR COOLING FAN RIGHT ANGLE DRIVES A AND B -- Continued

0015 00

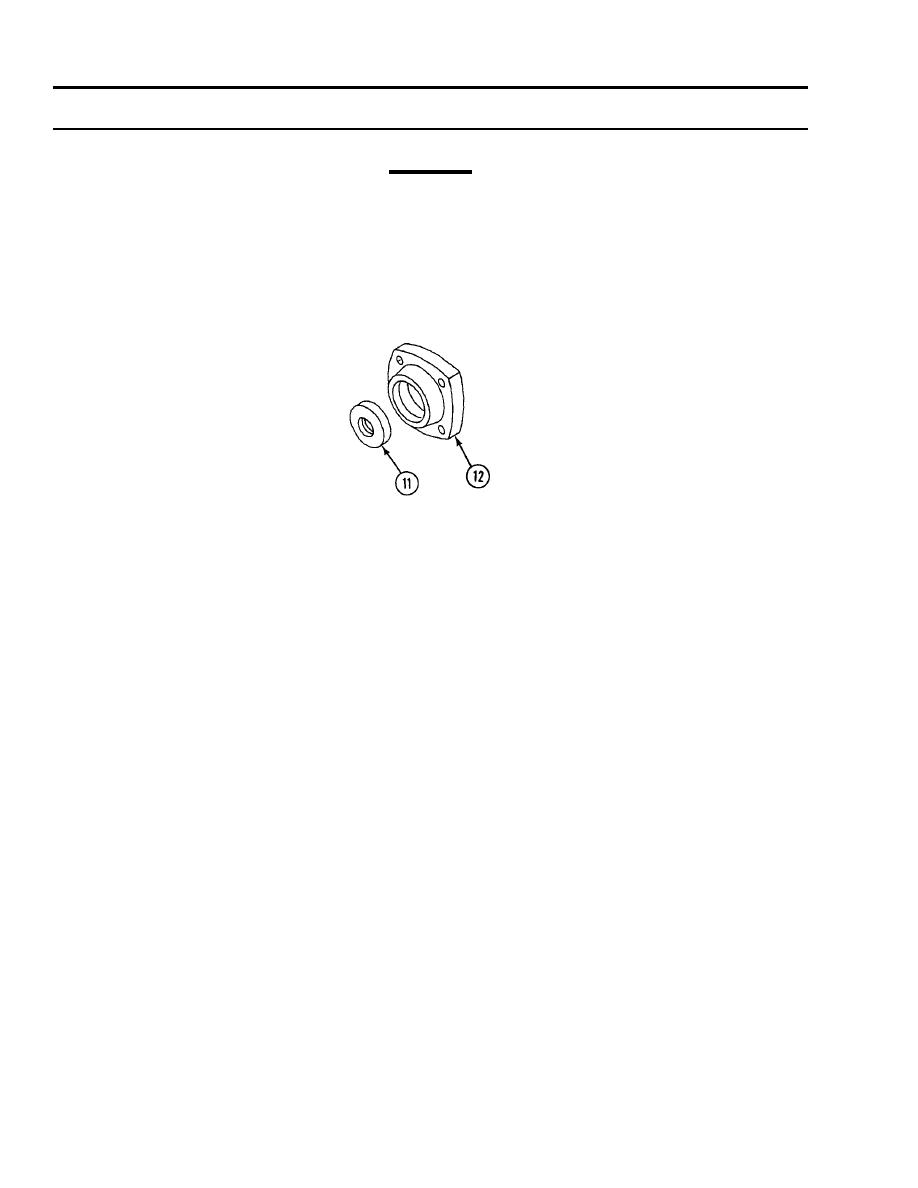

CAUTION

To prevent damage to encased oil seal, do not press seal beyond face of bore. After installation

seal must be flush with outer surface.

10. Install new encased oil seal (11) in bearing retainer housing (12) as follows:

a.

Clean mating surfaces of oil seal (11) and bearing retainer housing (12). Apply a thin film of sealing compound to

outer edge of oil seal.

b.

Press oil seal (11) into bearing retainer housing (12). Use arbor press.

11. Determine thickness of shim (1) as follows:

a.

Without installing shim (1), install cartridge assembly (2) and bearing retainer housing (3) on housing (4) with four

new key washers (5) and cap screws (6). Tighten screws, but do not bend tabs on key washers at this time.

b.

Measure inside diameter A in housing (4). Use caliper set.

c.

Measure dimension B between inside edge of housing bore and unetched portion on face of bevel gearshaft. Use

vernier height gage.

d.

Calculate shim thickness using above measurements and M.D. dimension (etched on gearshaft) recorded in Step 8.

Shim thickness = M.D. -A/2 + B.

e.

Peel new laminated shim (1) to calculated thickness or next thinner laminate.

f.

Remove four cap screws (6), key washers (5), bearing retainer housing (3), and cartridge assembly (2) from

housing (4).

0015 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |