|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-238-34

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS), INCLUDING

0014 00

LUBRICATION INSTRUCTIONS -- Continued

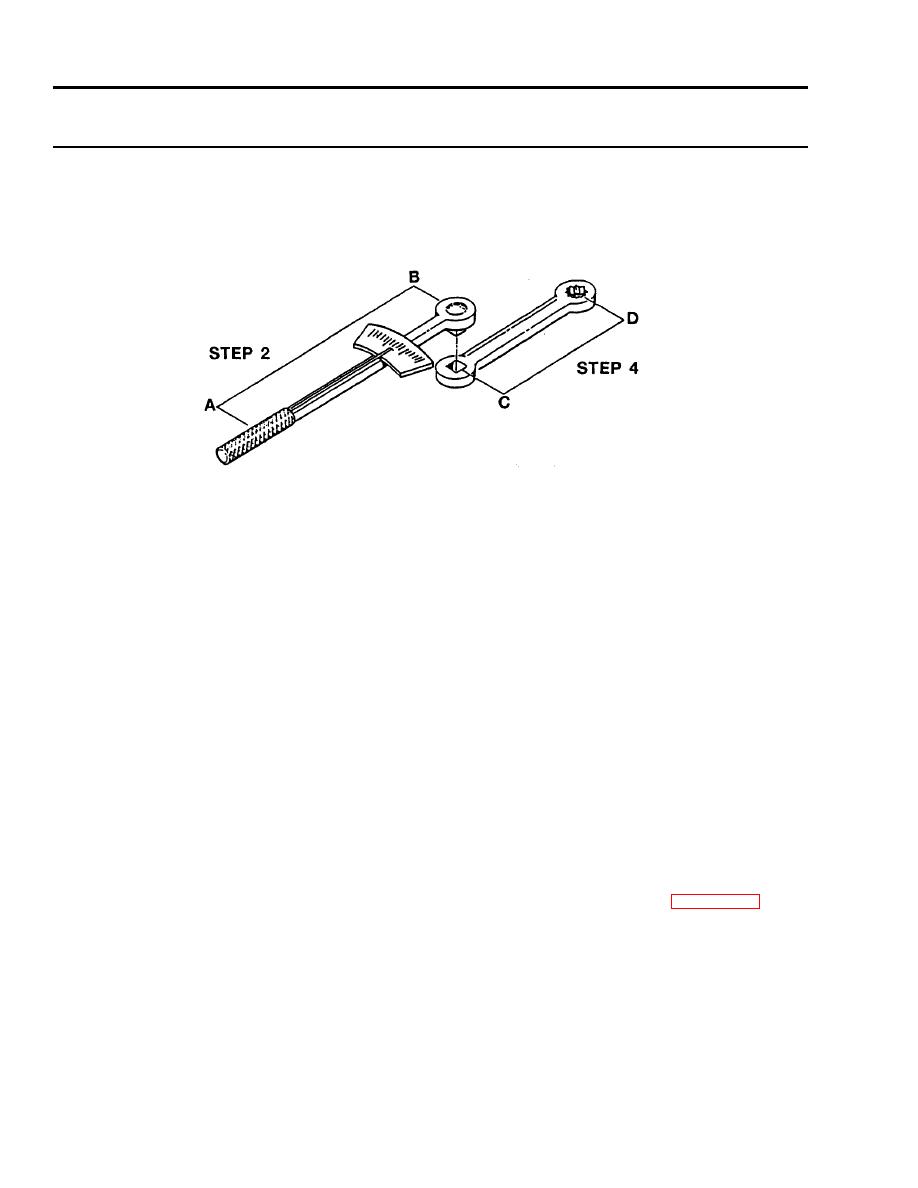

NOTE

Setting the torque wrench dial at the reading found in Step 7a7 will deliver the required torque

at the end of your adapter.

Example: (Metric equivalents omitted for clarity).

1) 40 lb-ft required.

2) 12 inches.

3) 12 x 40 = 480.

4) 4 inches.

5) 12 + 4 = 16 inches.

6) 480/16 = 30 lb-ft.

7) Torque wrench dial setting = 30.

CLEANING

8.

GENERAL. Cleaning is very important. All parts must be cleaned well and kept clean during maintenance. Dirt or

foreign matter can cause malfunctions and equipment failure. General cleaning procedures are detailed in the following

steps. Special cleaning procedures are covered in the task relating to the specific part. Clean after repair and before

assembly.

9.

CLEAN EVERY PART. Clean every part well after disassembly and before assembly or installation. Clean parts such

as housings, covers, and dipsticks before disassembly. Avoid getting dirt and foreign matter in a system.

10. HANDLE WITH CARE. Use care when handling parts during cleaning and maintenance. Nicks, scratches, dents, and

burrs can prevent proper assembly or cause malfunctions after assembly.

11. AVOID ABRASIVES. Except where specially called for in a task, don't use abrasives, files, wire brushes, or sharp

tools. On some surfaces, finish is important to the operation of close fitting parts.

12. REMOVAL AGENTS. Remove gum or old grease deposits by soaking parts in cleaning compound WP 0035 00, Item

4. Scrub with a brush. Use crocus cloth to remove minor surface defects.

0014 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |