|

|||

|

|

|||

|

Page Title:

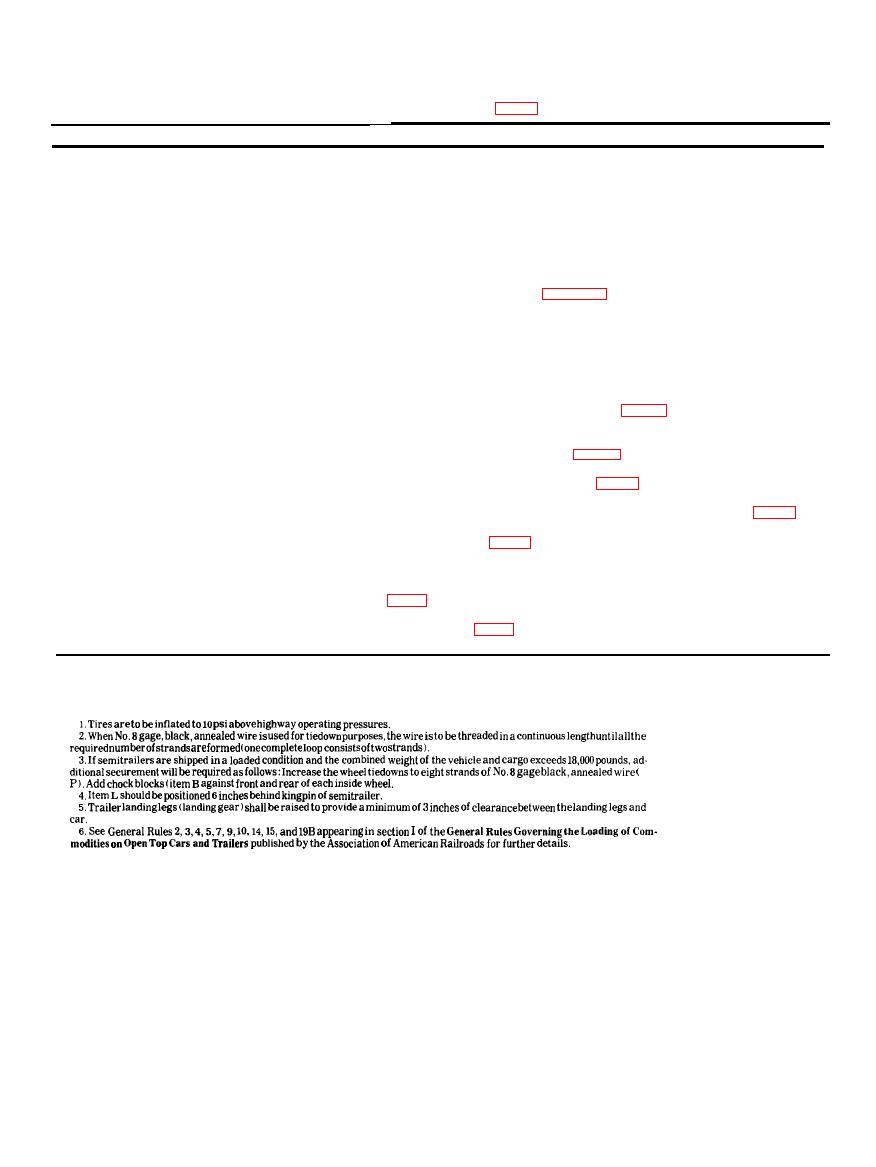

Table 7-2. Application of Materials for Blocking and Tiedown of Typical 12-Ton Semitrailer on CONUS General-Purpose Flatcars |

|

||

| ||||||||||

|

|

TM 55-2330-200-15-1

Table 7-2. Application of Materials for Blocking and Tiedown of Typical 12-Ton

Semitrailer on CONUS General-Purpose Flatcars (Fig 7-1 and 7-2) Continued

Item

No. required

Application

2

F

Lumber, 4- x 4-in. x length-to-suit. Toenail to item E with four 16d nails.

G

4

Lumber, 4- x 4-in. x length-to-suit. Double bevel each end. Cut to insure full bearing for item

L. Toenail to items E and F with two 16d nails at each end.

H

2

Lumber, 2- x 4- x 30-in. Nail to items F and G with three 12d nails at each joint.

2

J

Lumber, 4- x 4-in. x length-to-suit. Double bevel each end. Cut to insure full bearing for item

L. Toenail to item F and to car floor with two 16d nails at each end.

K

1

Lumber, 2- x 4- x 62-in. Nail to items F and J with three 12d nails at each joint.

L

2

Lumber, each to consist of one piece, 2- x 4- x 37-in. and one piece, 2- x 6- x 37-in. Nail lower

pieces to top of items F, G, and J with two 12d nails in each of the items. Offset vertical

joints as shown in detail 3, circle insert X, figure 7-2, and nail top pieces to lower with six

12d nails each.

1

M

Lumber, 2- x 6- x 24-in. Nail to item L with six 12d nails.

N

4

Lumber, each to consist of two pieces, 2- x 4- x 18-in. Nail first piece to item E with four 30d

nails. Nail second piece to first in the same manner.

2

0

Lumber, each to consist of two pieces, 2- x 4- x 12-in. Nail first piece to car floor, against item

J, with three 30d nails. Nail the second piece to the first in the same manner.

4

P

No. 8 gage black annealed wire, six strands. Pass through the spokes or holes in the rear

wheels and through the car stake pockets (detail 6, item P, fig 7-2). Wires should be at-

tached to wheel above the midpoint and the twisted wire tiedowns installed so they form an

X across face of wheel. Twist taut with a rod, bolt, or suitable length of 2- x 2-in. lumber,

and secure to preclude unwinding (detail 5, item P, fig 7-2).

4

Metal fillers sufficient to provide a suitable radius must be used to protect wire at stake

Q

pockets and applied to prevent dislodgement (detail 5, fig 7-2).

4

Wire rope, -in. Attach through the semitrailer front and rear tiedown provision, in a com-

R

plete loop, through the stake pocket on the same side of the car (detail 4, item R, fig 7-2). A

thimble is to be placed at the bottom of each stake pocket and secured to wire rope with

cable clip (clamp) (detail 4, item T, fig 7-2).

Clamps, -in. Secure the ends of the wire rope, at the overlap area, with four clamps each,

24

S

and space 3-in. apart with a minimum of 6 in. from ends of cable. Place one additional

clamp to secure thimble and wire rope together at each tiedown provision and stake pocket

(detail 4, item S, fig 7-2).

Thimble, open type, -in. Place one at bottom of each stake pocket and through each vehicle

8

T

tiedown device (detail 4, item T, fig 7-2).

See item L above.

X

GENERAL INSTRUCTIONS

7-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |