|

|||

|

|

|||

|

Page Title:

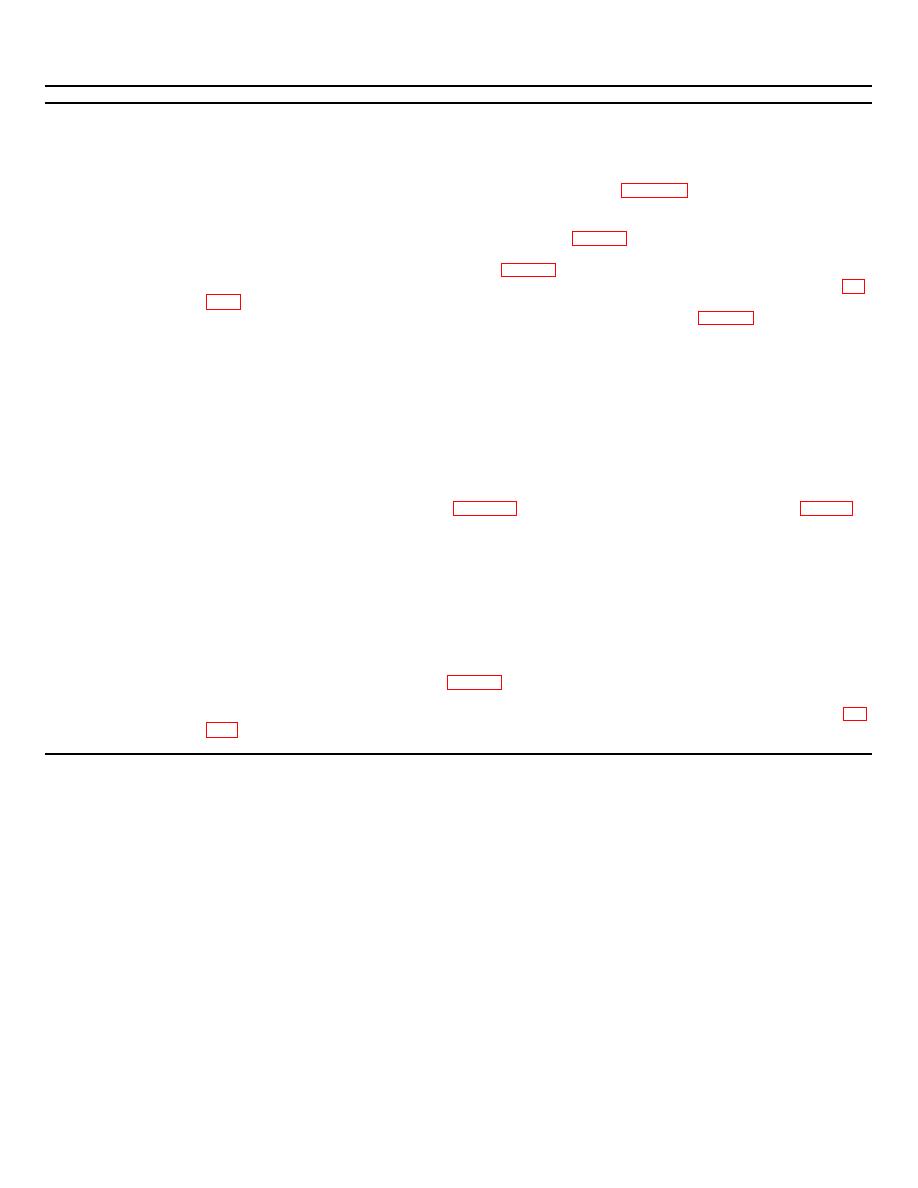

Table 7-6. Application of Materials for Blocking and Tiedown ofLACV-30 Components Shown in Figures 7-7, 7-8, and 7-9 |

|

||

| ||||||||||

|

|

TM 55-1930-218-14

Table 7-6-Continued

Item

No. required

Application

C

12

Strapping boards, 2- x 4- x 10-inch lumber, beveled to fit top edge of bottom module. Position under steel

strap (item F) to protect flanges and corners of bottom module.

D

10

Strapping boards, 1- x 4- x 36-inch lumber. Position under steel straps (item F) crossing top modules.

E

3

Plywood, 3/4- x 8- x 24-inch (approximate). Bolt to flanges of side decks at three places to maintain

separation.

F

11

Steel straps, 1 1/4- x .035-inch x cut-to-length. Position as shown in figure 7-7. Each strap is fabricated by

looping a length of strapping through the stake pocket on each side of the railcar, with a pad (item G)

between the strap and the stake pocket. The loops are formed by attaching two seals (item H), butted

together, at least 18 inches above the stake pocket (detail 3, fig 7-10). Overlap the two lengths of strapping

at the top of the load, tighten, and join with two seals (item H) butted together. All seals at strapping joints

must have two pairs of crimps per sea] (detail 4, fig 7-10).

G

22

Pad, 1 1/4- x .035- x 18-inch steel strap. Position under and seal to item F at each stake pocket (detail 3, fig

H

88

Seals, steel strapping. Two seals required for joining strap at each joint (detail 4, fig 7-10). One seal

required for securing each pad (item G) to strap.

J

1

Lower end brace, 4- x 8-inch x 9-foot. Stand on 4-inch edge against the end of the bottom module and

toenail to the railcar deck with ten 40d nails.

K

4

Backup cleats, 4- x 4-inch x 4-foot. Place against item J and nail to railcar deck with five 30d nails through

each.

L

1

Lower end brace. Consists of four pieces of 4- x 6-inch x 4-foot lumber nailed to one piece of 4- x 8-inch x

9-foot lumber with two 40d nails through each 4- x 6-inch x 4-foot piece. Place the 4- x 8-inch x 9-foot piece

against the end of the lower module and toenail the lower ends of the 4- x 6-inch x 4-foot pieces to the

railcar deck with two 40d nails through each side of each piece.

M

4

Backup cleats, 4- x 4-inch x 4-foot. Place one against the end of each 4- x 6-inch x 4-foot piece (item L) and

nail to the railcar deck with five 30d nails through each.

N

2

Wire rope, 3/8-inch. Locate as shown in figure 7-7. Form a loop through the railcar stake pocket, (fig 7-11),

pass the wire rope around the end brace, and form a loop through the stake pocket on the opposite side of

the railcar. Position the wire rope in the notch of each end brace. Place a thimble (item Q) underneath the

wire rope at each end of the end brace. The wire rope may be tensioned with an appropriate size come-

along mechanical hoist or equal tensioning device.

O

2

Wire rope, 3/8-inch. Form a loop through the railcar stake pocket, loop the wire rope around the side deck

mooring bit, then through another stake pocket. The angle between the wire rope and the railcar deck

should be as near to 45 degrees as possible. Place a thimble (item Q) on the wire rope where it passes

through the stake pocket. Tension as for item N.

P

36

Clamps, 3/8-inch. Secure the wire-rope loops with three clamps spaced 2 1/2 inches apart, leaving a

minimum of 6 inches from end of rope (fig 7-11). Place one additional clamp to secure thimble (item Q) and

wire rope together at stake pocket.

Q

Thimble, open-type, 3/8-inch. Place one at bottom of each stake pocket where wire rope passes through (fig

7-11). Attach thimble to wire rope with one clamp (item P). Place one thimble underneath the wire rope at

each end of the end braces.

7-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |