|

|||

|

|

|||

|

Page Title:

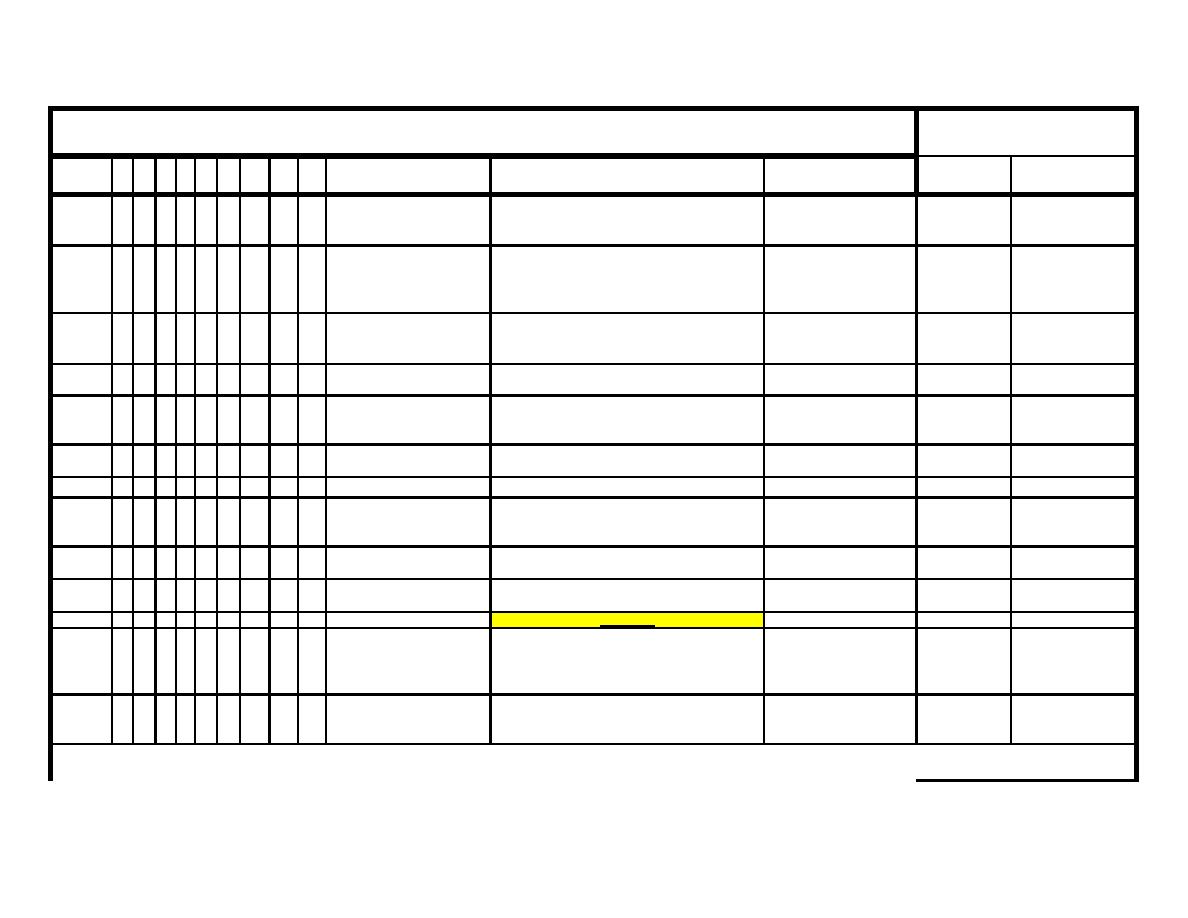

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

X

Liquid Refrigerant

Check liquid refrigerant sight glass to make

Add/recover refrigerant as

System is

certain that the system is fully charged.

necessary. Troubleshoot

over/under

and repair leaks.

charged.

X

Condenser and Evaporator

Check both the condenser and evaporator fan

Repair/replace as

Unusual noise or

Fan Motors

motors to make certain that they are operational

necessary.

vibration

and that the fans are tight and secure.

X

Door Gaskets

Check that door gaskets and breaker strips are

Clean as necessary.

clean. Check door gaskets for dry rot and

Replace door gasket as

necessary.

X

Inspect dispenser valves to ensure they are

Repair/replace as

79

Milk Dispenser #NSF-SK-2

secure on valve holders.

necessary.

X

Compressor

Inspect for proper operation of compressor.

Report abnormal

Unusual noise or

compressor noises to

vibration

supervisor.

X

Duct Panel

Inspect air duct panel and beneath unit for

Remove restrictions.

restrictions.

X

Condenser

Remove rear panel and clean condenser area.

Clean as necessary.

X

Check that ventilators are cleaned daily.

80

Dishwasher Exhaust

Ventilator Control Cabinet

X

Detergent System Fittings

Check that all fittings are air tight.

Tighten fittings as

necessary.

81

Hydraulic Watertight Door

CAUTION

Do not operate door with low and high pressure

shutoff valves closed. This will back-pressure the

local hand pump and cause the shaft seals to

rupture.

X

X

Bleed Off

Check that hydraulic system is bled at all high

Turn bleeder valve handle

Bleeder valve handles

points to remove trapped air.

to release trapped air.

unserviceable.

LSV PMCS

Change 12

2-287

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |