|

|||

|

|

|||

|

Page Title:

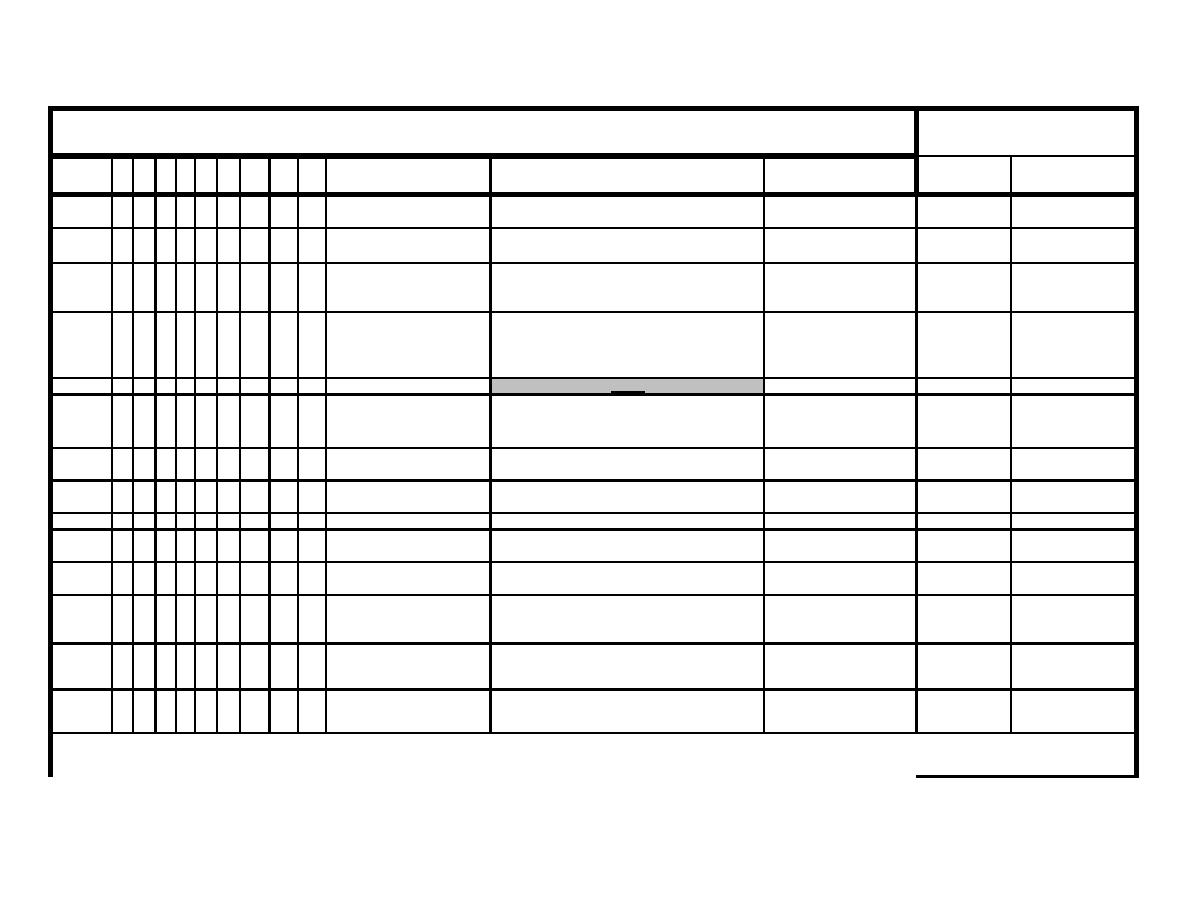

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

X

Fuel Pressure

Check fuel pressure gauge for proper fuel

Troubleshoot and repair as

necessary.

pressure (40 to 50 PSI).

X

Cooling System

Check gauge for proper operating cooling

Troubleshoot and repair as

Temperature greater

necessary.

than 180 Degrees F.

temperature (165 to 180 Degrees F).

X

X

Oil Level

Check engine oil level. Maintain the oil level

Add oil as necessary.

Low oil level.

between the add and full marks on the dipstick.

X

X

Check reduction gear unit for debris, foreign

Remove foreign debris.

Debris, foreign objects

36

Reduction Gear

objects and loose or broken fittings. Refer to

Repair loose or broken

remain wedged or

TM 55-1915-202-24&P

fittings.

lodged in components.

NOTE

Inspection of the reduction gear unit should be

accomplished prior to startup operational checks

of the main propulsion engines.

X

Oil Level

Check that oil level is filled to upper dipstick mark. Add oil as required.

Low oil level

Refer to TM 55-1915-202-24&P.

X

Leaks

Inspect reduction gear unit for oil or water leaks. Repair leaks, refer to unit

Class III leaks.

maintenance.

X

X

Exhaust Stack

Check that exhaust stack is clear.

X

Clutch Control

Check that engine speed and clutch control air

Place in neutral.

valve is in neutral position.

X

Air Transfer Valve

Check that control air transfer valve is in local

Place in local position.

position.

LSV PMCS

Change 12

2-269

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |