|

|||

|

|

|||

|

Page Title:

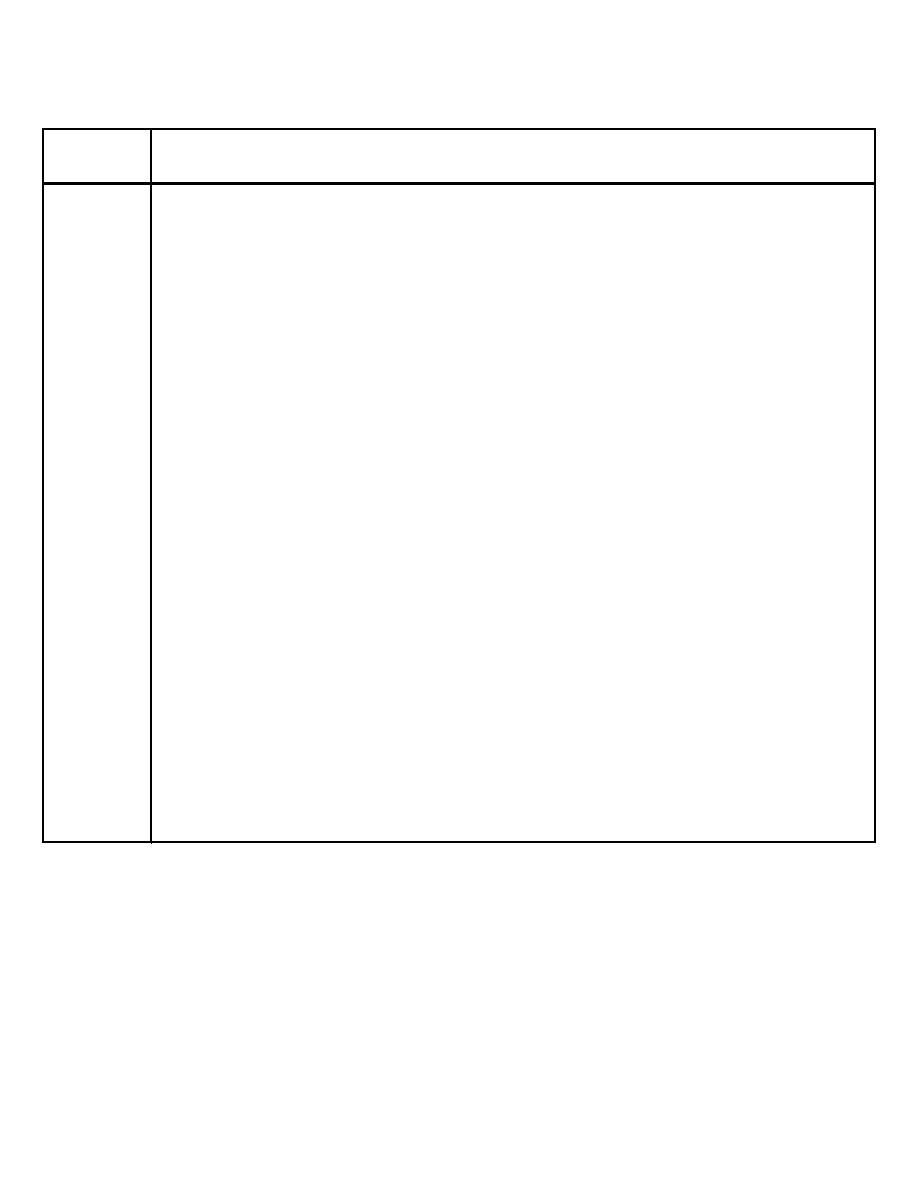

SECTION IV. REMARKS - EMERGENCY GENERATOR SET |

|

||

| ||||||||||

|

|

TM 55-1905-223-24-4

SECTION IV. REMARKS

EMERGENCY GENERATOR SET

REFERENCE

REMARKS

CODE

A

Depot maintenance will be performed on a case by case basis subject to approval and funding by the

National Maintenance Point (NMP).

B

Upon failure, determination should be made to evacuate for rewind or to salvage at general support

level.

C

This item is a candidate for direct exchange with the vendor.

D

Keep hands out of the path of the spring loaded tensioner.

E

Hold the fuel pump delivery valves securely when loosening the high pressure lines. Be sure the lift

pump connection and fuel pump connection is held securely when loosening the low pressure and fuel

supply lines.

F

When rust has formed on the hold down nut, the injector can turn in the bore when nut is loosened. This

will cause severe damage to the head by the, injector locating ball cutting a groove in the bore. Soak the

hold down nut with rust penetrating solvent for a minimum of 3 minutes.

G

If honing or grinding is required on valve or cylinder walls, evacuate to general support level.

H

Do not remove the timing pin assembly unless a new gear housing assembly is to be installed.

I

Mark each rod cap and piston according to the cylinder.

J

Lock the acrankshaft before removing the flywheel.

K

The main caps should-be numbered.

L

Repair at O level is to replace resistor assembly. Repair at F level is total repair to unit.

M

Repair at C level is to replace hoses and damps. Repair at O level is to replacetubes and guards. Repair

at F level is total repair.

N

Repair of this item is by replacement.

O

The starting motor is a candidate for direct exchange with the vendor.

Change 4 B-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |