|

|||

|

|

|||

|

Page Title:

Operating Instructions |

|

||

| ||||||||||

|

|

TM 9-6685-202-14

c. If the vacuum test chamber is to be maintained

at 15 inches of mercury absolute pressure, the

handwheel is adjusted until the desired pressure is

indicated on a manometer or indicator connected into

the system. Turning handwheel (1) clockwise increases

the absolute pressure and counterclockwise decreases

the absolute pressure. When operating at 15 inches of

mercury absolute pressure, the net resultant force of the

bellows and spring equals that applied by a pressure of

15 inches of mercury absolute, and just sufficient air

passes through port (10) to maintain equilibrium. If the

pumping rate of the source of vacuum or the

atmospheric pressure changes, the bellows immediately

reacts and throttles the air inlet so that equilibrium is

maintained.

d. In order to use the regulator on a pressure

system, connect the pressure source to air inlet (8) and

the pressure test chamber to test connection(6).

Vacuum throttling valve (4) is cracked and allowed to

vent to atmospheric pressure.

CAUTION

Take care when approaching the

limits of the operating range so that

the regulator is not forced past the

internal stops. As soon as the crank

wheel assembly binds, stop turning

the handle. If it binds at any point

other than the limit of the operating

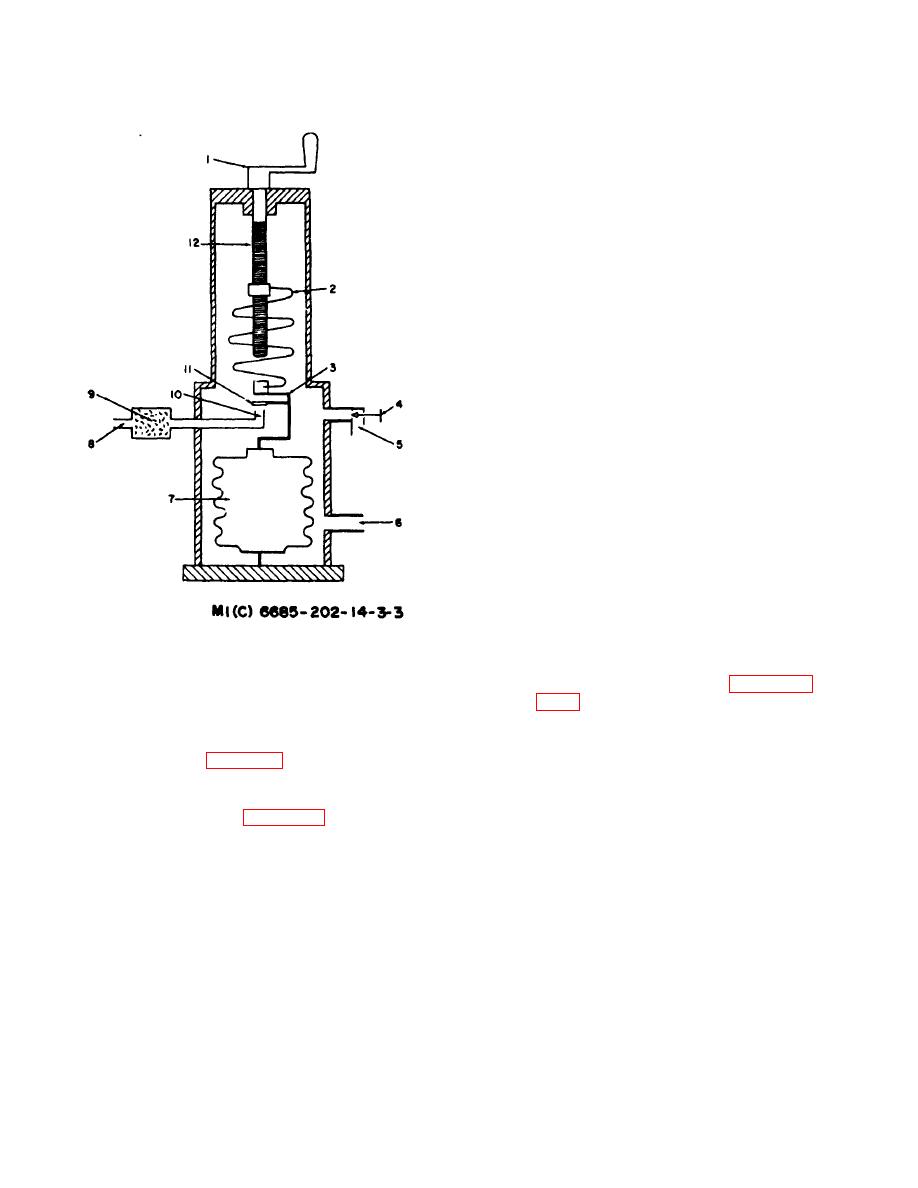

Figure 3-3.

range, (3 to 60 inches of mercury

Constant vacuum regulator - operated wider

absolute pressure) disassemble the

vacuum.

regulator as described in paragraph

NOTE

mechanism.

The numbers in parenthesis shown

3-9. Operating Instructions

below refer to figure 3-3.

a. General. Correct sighting of the mercury level

b. The operation of the constant vacuum regulator

and reading of the barometer scale must be thoroughly

is schematically shown in figure 3-3. The source of

understood prior to using the barometer.

These

vacuum is connected to the vacuum pump connection

operations are explained in this section and are used in

(5). The vacuum test chamber, barometer, or apparatus

all applications of the barometer. These applications

where control of vacuum is desired is connected to the

include operating the instrument as a barometer, to

test connection (6). Vacuum throttling valve (4) is

calibrate altimeters, as a gage-pressure manometer, as

opened and adjusted to suit the capacity of the vacuum

a differential-pressure manometer, and as an absolute-

pump. Air inlet (8) with air filter (9) is left open to

pressure manometer. The procedures for checking the

atmospheric pressure. When adjusting handwheel (1)

level of mercury in the barometer and for removing an

is turned clockwise, adjusting screw (12) stretches

air bubble from the tube are also included.

control spring (2). The spring tension is transmitted to

bellows (7) by spring and bellows connector (3). Valve

b. Sighting the Mercury Level. Proper sighting of

disc (11) is positioned over valve port (10) by spring and

the mercury level is essential for accurate and

bellows connector (3), and valve disc (11) moves away

consistent readings. Proceed as follows:

from valve port (10) as the bellows (7) expands, and

toward valve port (10) when the bellows contracts,

thereby controlling the flow of air through the regulator.

3-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |