|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 94940-462- 14&P

NO. ATM-1

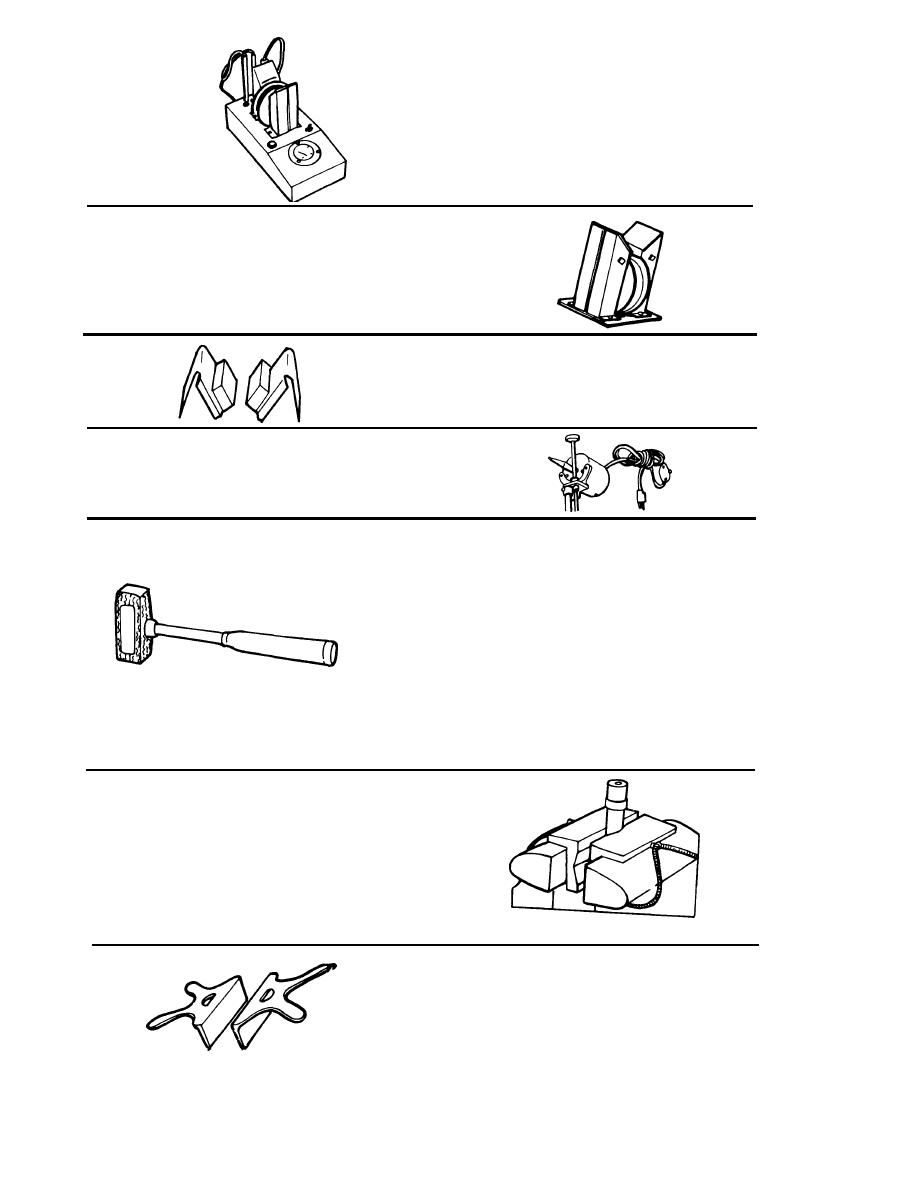

ARMATURE TESTER

The basic unit for armature repair. Extra laminations and

winding for strong magnetic field. Has 0-30 ampere meter

and double prods to locate open and short circuits. Shock-

proof test circuit with ruby light and single prods to locate

grounds. Used with 115V 60C current. 12" x 6" x 8 1/2" high.

NO. AT-2

ARMATURE GROWLER

Has same laminations and winding os ATM-1. Locates shorts,

opens, and grounds by means of a hack saw blade. Used

with 115V 60C current. 4 1/2" x 4 3/4" x 6" high.

NO. ATJ

REDUCER ATTACHMENT

For testing small armatures. Reduces throat opening on ATM-1

and AT-2 from 1 1/4" to 5/16". Keeps armature up in magnetic

field. Clamps on growler jaws.

MOTORIZED UNDERCUTTER ASSEMBLY

NO. 3000

For converting No. B-10 lathe to newer No. B-15 type with

motorized undercutter. Complete as shown with 115V 60C

motor.

NO-MAR HAMMERS

NOS. 1A, 2A, & 3A

The strongest, safest, most reliable fiberglass handles made

are epoxy-bonded to unique aluminum aloy heads that are

non-marring, non-sparking, and non-spalling. Heads will not

crack, loosen, fly-off, or become misaligned. Handles have

rubber grips to provide a secure cushioned hold that reduces

vibration and user fatigue. Minimum rebound. Long life.

NO-MAR HAMMERS

NOS. 2B & 2C

These combine the safety and comfort features of our non-

marring, non-sparking, non-spalling aluminum alloy hammers

with the heavier blow of brass or copper. Epoxy-bonded to

fiberglass handles, as above. No. 2B Brass is more durable,

No. 2C Copper is softer; but both are long-lasting, heavy

duty hammers.

BRASS VISE JAWS

NO. BVJ

These heavy brass inserts help prevent damage to expensive

parts that are clamped in a vise. Faces are 3/8" thick, 1 3/4"

deep, and 4" wide. Spring straps easily slip over the vise

jaws to hold inserts in place and to center them automatically.

The faces have flats, plus both vertical and horizontal grooves

to grasp round parts. These cast brass inserts will save their

initial cost many times over long years of service.

NO. CVJ

COPPER VISE JAWS

Cast from #1 copper, these jaws provide soft, flat faces

that taper from 4 11/16" top width to 4 1/2" bottom width, are 1 5/16"

deep, and are at least 1/8" thick. Tabs can be bent to hold

inserts an the vise. An inexpensive way to avoid chewing up

parts with standard steel jaws.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |