|

|||

|

|

|||

|

Page Title:

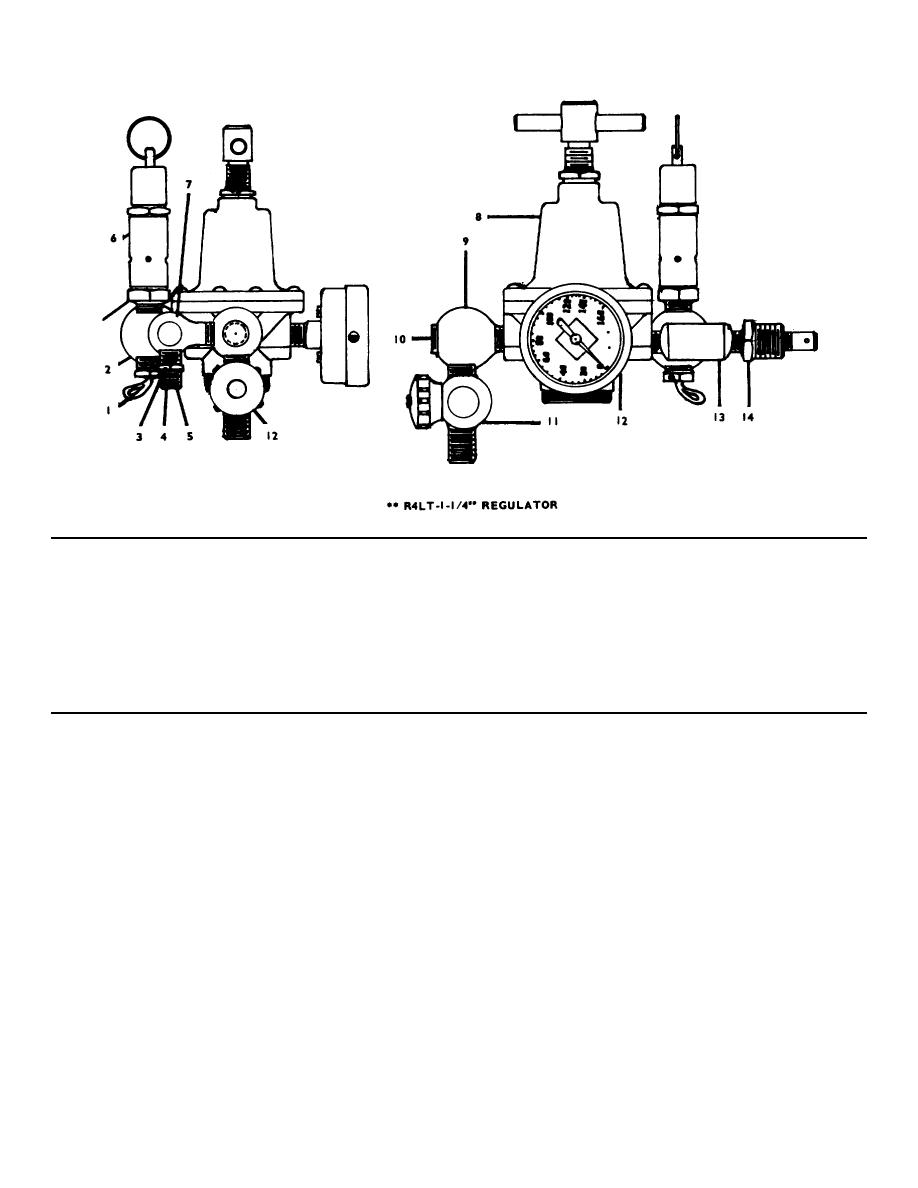

R4LT-1-1/4" REGULATOR WITH PARTS LISTED |

|

||

| ||||||||||

|

|

ASME-A3, 5, 10, 20, 30 AND 60 GALLON TANKS AIR REGULATOR PARTS

** R4LT-1-1/4" REGULATOR WITH PARTS LISTED

No. PART

DESCRIPTION

No. PART DESCRIPTION

1. HRV-1/4" Release Valve

8.

R-65-1/4" Regulator

2. HF-564L 3 Way Tee

9.

HF-560L 4 Way Tee

3. HF-33S Coupler W/Strainer

10.

1/4" Allen Pipe Plug

4. U-811 Air Inlet Strainer

11.

HF-1 /4" Valve

5. DH-74 Retaining Ring

12.

GB-2"-60# or GB-2"9-160# Gauge

6. PU-725 ASME Pop Valve

13.

HF-342-1/4'* 3 Way Tee

7. HF-1/4"-90 Elbow

14.

HF-34AS Splash Coupler

** Specify 1 or 2 Outlets.

Air pressures are required, heavy materiel requires

higher Pressure. The Speed of Application depends

CAUTION

upon the Size of Spray Gun. Air pressures and

When filling Tank with Inflammable materials,

C.F.M. capacity of Multiplehead.

explosive vapors will ignite from Static or

2. Do not use excessive Air pressure on Fluid in Tank

Electric Spark due to contact of metal can with

as this will force the Paint out faster than the Spray

top of Tank. When using this or any other type

Gun can Atomize it, causing rough Finish. The Tank

material .... Do Not forget the Fire and Safety

Pressure should range from two pounds and higher,

Regulations. Do not use strong Alkali Solutions

depending upon the consistency of material, the

an they will destroy the Galvanized Lining of the

length of Fluid Hose and height the material must be

Tank. Certain Material my be allowed to stand In

raised above the level of the Tank. Generally, the

Tank for days, providing connections remain

Pressure should be increased 1 lb. per ft. of elevation

tight and no Air gets Into Fluid Line to cause

and regulated so the material flows slowly from the

material to harden. Make sure proper room

Spray Gun Fluid Tip when Atomizing Pressure is

Ventilation Is provided during operation and use

shut off and Trigger Is drawn back.

of any type material.

Approved Ventilating

3. After Fluid Regulator Is properly Regulated,. adjust

Equipment should be used.

Atomizing Pressure which gives satisfactory results

so fumes and mist will be held to a minimum and

waste of material eliminated. Light materials require

AIR SUPPLY

10 to 30 lbs. Pressure for Atomization. medium

1. An adequate Supply of Compressed Air is essential

consistency Finishing materials 30 to 50 lbs. and

for proper Atomization of all types of Coating and

heavy material 50 to 100 lbs.

Finishing materials. For light consistency Fluid, Low

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |