|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2990-206-34&P

3-6. REPAIR.

REPAIR COMPRESSOR HOUSING

TOOLS:

Hand file

1/4 to 3/4 inch diameter, 1/2 inch drive, stud remover and setter

1.

Smooth small nicks or raised metal using a fine hand

file.

Remove and discard loose or damaged stud(s) using

2.

stud remover and setter.

Drill a 21/64 inch (8.33 mm) hole to a depth of

3.

7/8 inch (22.211111).

4.

Tap a 5/16-18 thread using special Heli-Coil tap

(Heli-Coil Part No. 5CBB).

5.

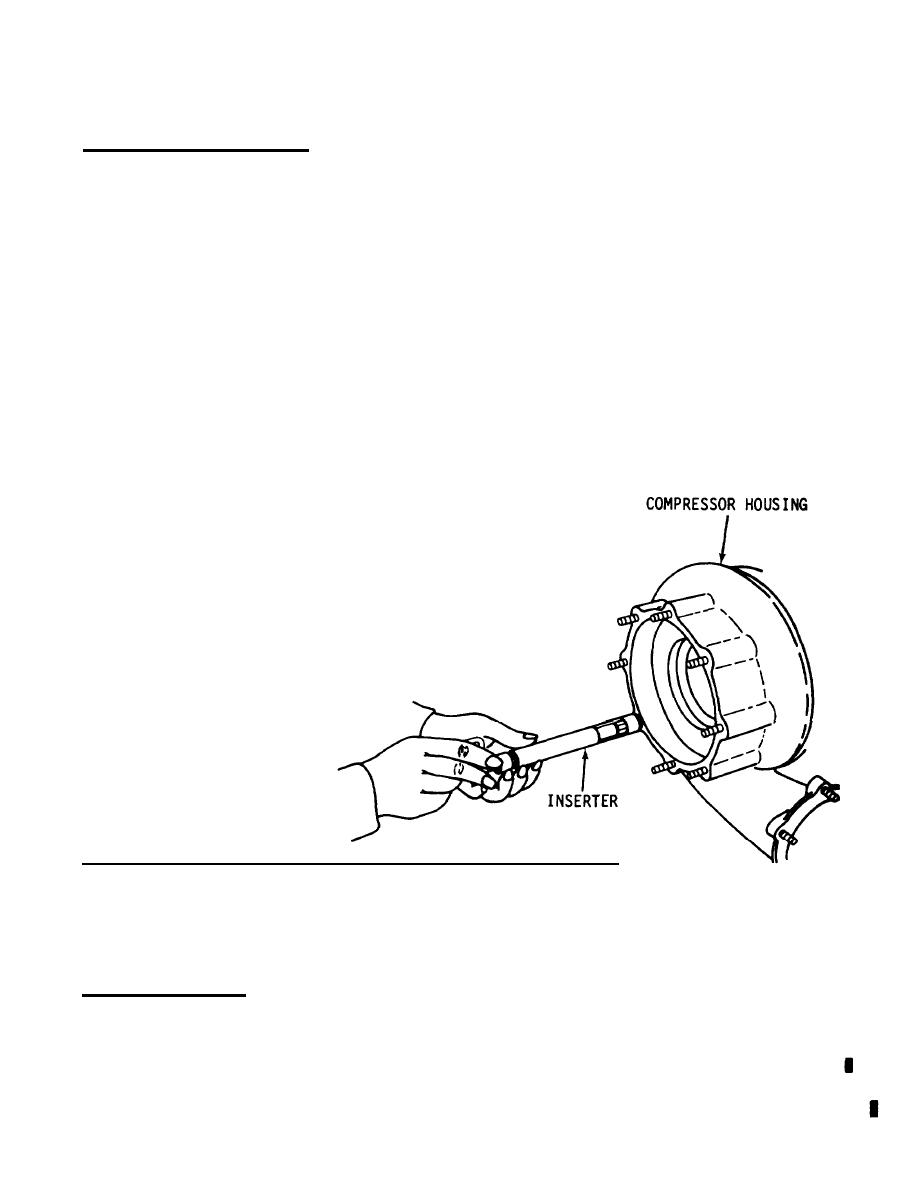

Install screw thread Insert, Part No. MS21208C5-20,

into threaded guide of screw thread inserter, Part

No. 3551-5, by S1OWly turning the pilot counterclock-

wise until the insert is flush with the end of the

inserter. Insert the pilot of the inserter into the

tapped hole, with the face of tghe inserter resting

solidly against the compressor housing. Slowly turn

the pilot handle clockwise until no further

resistance is felt. Remove inserter.

Using stud remover and setter, install coarse thread

6.

end of new stud, Part No. 400678, to a setting

height of 13/16 inch (20.64 mm).

REPAIR MOUNTING LEGS, OIL DRAIN TUBE, BACKPLATE, AND SHROUD

TOOLS:

Hand file

Smooth small nicks and raised metal using a fine hand file.

REPAIR HEAT SHIELD

1. Straighten minor bends.

2.

If heat shield cannot be restored to original con-

figuration, it must be discarded.

3-16.1

(3-16.2 blank)

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |